Hello,

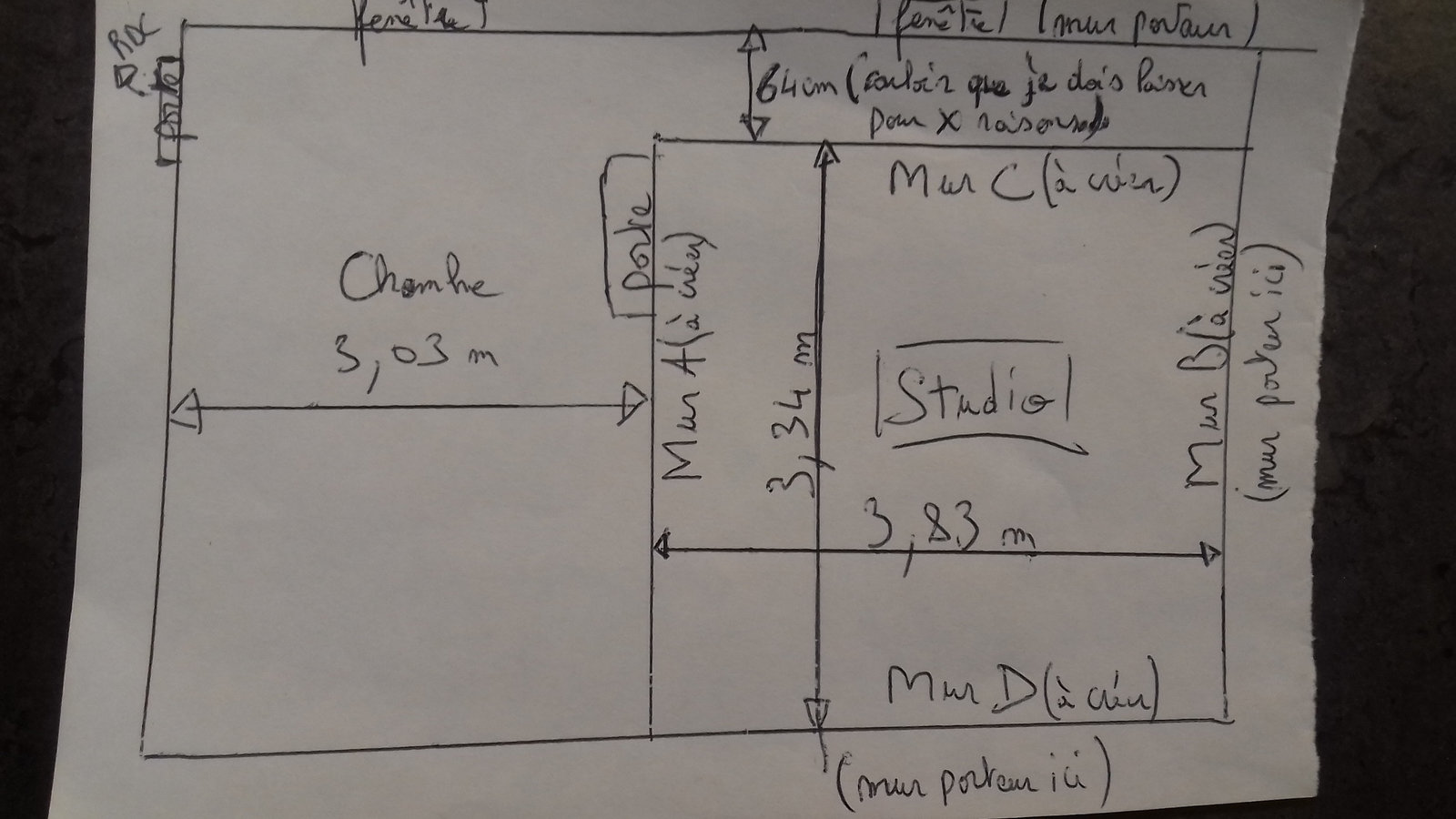

I post exceptionally because drummer from France I can hardly find advice for my sound insulation project. I intend to order the products below and do myself the work with a friend specializing in partitions. Already well advanced in my head and on paper, I have only 1 question. If you had a contact who knows these topics well it would be great to be able to ask him his opinion. I take any last advice to realize well this studio "box in the box", ground, walls, and ceiling based on mass-spring- mass. Here is the plan and the details of my play and my question, or rather seeking advice, is on the balance of these walls:

Does the ratio of rockwool vs masses seem balanced? (Or if it would take more mass or on the contrary more rockwool?)

Note that this apartment is in the basement, no neighbors below or on the sides (left, right, front, behind), but above only and the ceiling height is 2.15 m.

I will use rockwool 70 kg/m3, and that the heavy mass makes about 5 kg/m2 for 2.5mm, or in 5 mm 7.5 kg/m3, or in 10 mm 10kg/m3.

ba13 and ba18 are plates of plaster 13 and 18 cm thick.

(The details concerning the electticity, the light, are regulated, so I do not approach them)

- Floor : Because of this lack of ceiling height, but also because I have no neighbors below, I intend to do the ground quite simply: 5 mm (minimum) heavy mass on the entire surface floor + floating floor 14 mm = 1.9 cm. I know that my floor should not touch the walls (separation of a few mm) to separate, do not create bridges phonic.

- Wall A (where there is the door 82 mm/-50dB): ba 13 mm + heavy mass 20 mm (glued to ba13) + wood frame (100 mm depth) + in the frame rockwool 100 mm + empty air 10 mm + ba 18 mm + heavy mass 20 mm + acoustic Ba 13 mm = 19.4 cm (thicker wall because it looks on the rest of the apartment, and not on the load-bearing wall).

- Wall B (on very thick load-bearing wall): wood frame 100 mm + in the rock wool frame 100 mm + Ba 18 mm + heavy mass 10 mm + ba 13 mm acoustic = 14.1 cm.

- Wall C: Ba 13 mm + heavy mass 10 mm (glued to ba 13) + wood frame 70 mm + in the rockwool frame 70 mm + ba 18 mm + heavy mass 10 mm + ba 13 mm = 13.4 cm.

- Wall D (on thick bearing wall which gives on cellars): As wall B.

- Ceiling: Glue heavy weight to the original ceiling. But before fixing the acoustics shroud (sustainers) in which we enter the lines (rods) to create a frame to put over the rock wool, and screw to the frame of the heavy mass previously glued to the ba13. Total: 20 or 22 cm.

(Note that some rubber bands will be used mainly on the ground so that the wood frame does not touch the ground, so to separate, do not create sound bridges between the tiles and the walls. They will be useful in general construction everywhere necessary if it will break any bridge possible phonic between two "hard" materials.)

Best regards.

(Here are the products used) :

- https://www.amazon…

- https://www.acousti…

- https://www.leroyme…

- https://www.leroyme…

- https://www.leroyme…

- https://www.leroyme…

Then one of the following 3 heavy masses (must re compare, there are the data sheets) :

- https://www.audioph…

- https://www.audioph…-polymere-adhesif-500x600mm-03m-p-10698.html

- https://www.pierree…

Comments

If i am not wrong, i think the extremes of the ceiling need to b

If i am not wrong, i think the extremes of the ceiling need to be separate by Joist tape (called also Confort silent / neoprene Joint) like in this draw isn't it ?

Here is the product :

https://www.greengluecompany.com/products/noiseproofing-joist-tape

https://www.greengluecompany.com/products/noiseproofing-joist-tape

I forgot a very important question. I don't know if we need to do the walls first (like in this first picture )or the ceiling first like in this second picture (and if the ceiling first the Joist tape will be at the top of the walls) ? I think it's logically before the walls to the top of the wood structure and after the ceiling (ceiling and walls separate by resilient bands)

And under the wood structure, some says i don't need to put, fix resilient under it (between wood structure and floor tile), some says yes like in this picture :

ps : there is not a lot of information in France about insulation and those pictures i send from the beginning are, after best research, the best pictures, draws we can found.

Sorry.

jerem1, post: 461075, member: 51587 wrote: Thank you very much.

jerem1, post: 461075, member: 51587 wrote: Thank you very much.

- I just need to translate Rod's book with Word Office (there is an option to do it), it's easier for me, and i will be ready.

- For the different Risc, i note it. I will see with the technician that help me because he gonna see with me and better than me the purpose of each.

- It is also very good to know that i need to leave minimum 1" (so minimum 2.5 or 3cm) between rock wool and the walls or the ceiling.

So everything is really clear now. Just need to see, brief the technician and command the products.

- But the last little hesitation, but it is note very important because the result is i think quite the same, is for the soil. I have two options : A thick parquet or a thick carpet. As we see in that discussions, Rod doesn't recommend carpet because "It really is going to just suck the high frequency life out of it". But i am not sure 10m2 of carpet in that little space will make a significant problem on high frequencies. That's why he and some others recommend parquet because (in all the case where you can't do a structure on the soil with anti-vibrations pads/studs) every material you simply put on the soil is close in acoustic qualities so it's better to chose an esthetic one and mostly parquet is better because if the carpet takes to much high frequencies, it can't be difficult to rebalance, make the treatment on the walls (foams, bass traps...). So the advantage of the parquet is that i could take less risks, because i can do more precisely the the treatment by the walls..

Also he says : "Carpet won't help with that except for direct impact noise - not even one little bit.

For the purpose of room treatments - carpet is pretty bad - all is does is suck the life out of the room and leave is bassy - boomy......... not a treatment anyone would really recommend as anything even remotely effective for a recording studio environment......."

In that link gave by Ethan Winer, we saw that parquet is a little little bit better than other material, but there is no carpet in that board, so maybe carpet is little bit better than parquet but i quote above the possible problems with, of carpet.

So i need to chose between parquet and carpet. Some says parquet is better for the reasons i described, and others carpet will be better because a little better absorption (but not very much and in high frequencies only which can be no good because embarrassing for room treatment after or recording)

http://realtraps.com/art_surfaces.htm

https://www.gearslutz.com/board/studio-building-acoustics/596373-flooring-question.html#post6492225

To clarify, i was suggesting the use of carpet under the drums specifically. The rest of the floor would be left bare- parquet, tile, concrete, ect.

Carpet under the drums is a common practice.

Use of carpet on the walls is a common myth, which is what i think rod was mostly refferring to.

Use of carpet on an entire drum room floor is optional. At Normandy Sound the main room is parquet with drums on a carpeted riser, and the main vocal booth is carpeted. The booth is used for vocals, speaker cabs, and for drums when a tight, dry sound is needed.

At the end of the day the floor covering wont make or break your sound, and floor reflections are only generally used for ambience.

I stick by my original suggestion of a typical area rug under the kit, and the rest of the floor bare, as we do in the Triad Recording, and Normandy Sound, live rooms. This would be considered "standard" practice in drum tracking.

The rug helps mitigate reflections coming off the floor, and back into the snare mics, which can cause phase cancellizations. Should you need to, you can simply roll up the rug, and put it off to the side.

jerem1, post: 461076, member: 51587 wrote: If i am not wrong, i think the extremes of the ceiling need to be separate by Joist tape (called also Confort silent / neoprene Joint) like in this draw isn't it ?

Rod details the corner junctions for various assemblies, and includes drawings. None of the plans call for joist tape, so it is unessesary.

From your link:

"One of the biggest noise complaints is the sound of footsteps and squeaky floors. The squeaking occurs naturally when floors settle, and joists rub together with subflooring – but this is avoidable. The solution is Green Glue Noiseproofing Joist Tape. The tape creates a seal that prevents void spaces which occur as joists and subfloors dry and shrink."

It seems its main purpose is for joists where a subfloor is layed, to eliminate squeaks.

----

In general, once the new walls and ceiling are decoupled, either with clips, or an entirely new set of framing within the existing room, there is no need to decouple the ceiling from the walls, or walls from the floor.

So once the new walls, ect, are decoupled from the Existing Structure, there is no need for anything more. You dont need to decouple the isolation assemblies from themselves. In other words the isolation assemblies can touch each other. They just need to be sealwd properly.

To seal, non hardening caulking (silicone or butyl), backer rod, and staggered seams do the job.

As far as insulation, there is no need to use it anywhere but where you would for a typical wall frame - in the bays, the space between a joist, and the one next to it.

---

The new wall frames can be fastened directly to the basement floor, as rod describes in the books drawings.

There is no need to "float" the walls on brackets, ect. There could be a case for that on if your studio was located on the second or higher floors.

I appreciate your work researching, so yoy get this right. Planning is the key to studio designs that work well.

Yes of course i have always a carpet, rug just under the drum. B

Yes of course i have always a carpet, rug just under the drum. But for the all soil, ground, i'm still hesitant. I'm not reassure with floor tile (even if there is a rug under the drum). For sure you are right. And maybe it is psychological. For me doing something on the soil brings me closer to the idea of the "box in the box".

So i can do only carpet, rug under the drum and leave the floor tile as it is. It' a good idea, simple, and i save this precious space i miss. And also has the board above says (as you said also) there is not so much difference "acoustic" and vibrations between all materials.

Or i have those 3 options but so it's maybe not needed, necessary. In the third possibility there is a layer of wool, maybe it's good for vibrations, absorption ?

3 others possibilities : 1) On the all floor i put carpet (carpet which integrates for example foam underlay); 2) Thick floating flooring on the tiles (and i don't know if it is necessary to put under the parquet OSB wood plates before?) 3) An underlay of high density wool and over OSB plates wood, and over parquet, or an underlay of wool (+ plate to plaster insulation) + parquet (like in this video) :

But thank you again, you helped me a lot and everything is clear except i have like 4 options for the soil, ground(n). I will see the very last details and preferences with the technician who's doing the job with me. I think i will follow your advice to just keep the floor tile and put a carpet under the drumset.

- And thank you very much also for the decoupling question. I did not knew that the new walls and ceiling can touching each others. I thought resilient between them or a very little space air (few mm) was needed. But you said they can touch and the most important is just the decoupling from the original ceiling thanks to the wood ceiling frame, structure.

And also thank you for the question about the wall frames that can be, as you said, fastened directly to the basement floor tile, so no need Confort Silence/rubber joist in between walls and floor tile.

- It is just that point that i did not so much understood : "To seal, non hardening caulking (silicone or butyl), backer rod, and staggered seams do the job. As far as insulation, there is no need to use it anywhere but where you would for a typical wall frame - in the bays, the space between a joist, and the one next to it.". Because in my case i'm just gonna do the suspend wall with shrouds directly from the wood frame structure we gonna build. So i am not touching the bays or anything from the original ceiling.

I just need to translate with Word Office Rod's book because i have no forces to read it in english.

Thank you a lot for you help and encouragement.

I will come back post some pictures when it will be done.

Also i see, but it's maybe just a detail, that there is 2 kinds

Also i see, but it's maybe just a detail, that there is 2 kinds of shrouds that can be fixed to the wood frame new structure wee gonna build.

There are shrouds that are going under the wood boards like in those pictures :

https://www.acoustique-studio.com/sustainer-p25-10-pieces-c2x9061918

Or there are other shrouds that are fixed not under, but on the sides of the wood boards like in this video at 1.17 min : '">

or those pictures :

http://ekladata.com/6voLZ9XXzHVtEU1_K1CPG3scsro.jpg

Maybe there is a better way, solid way or something else. And also i think maybe in one of those two technical i will need to use thicker woods boards which is not so good, because thicker wood it is more space i loose for the suspended wall himself.

- For closing the walls there is no problem, no different solutions. I will show this video you send me if we got that kind of product fixed to the wood frame in further to close the walls.

Just in case : sorry i just understood earlier when you talked a

Just in case : sorry i just understood earlier when you talked about 2-3 layers of 15.8mm plaster drywall . You talked about something like this : https://designcenter.nationalgypsum.com/storage/components/thumb/30.jpg

But i want do it a differently : instead of using 3 layers of drywall i use 2 (1 of 18mm and the other of 13mm) but in between i don't have another layer, i have the heavy mass because it got really much density than a drywall (it got 10kg m2 density). Is what i described in my plan from the beginning.

Here is the product (i put between 2 layers of drywall). Heavy mass : https://www.audiophonics.fr/fr/amortissants/pinta-amortson-bi10a-phd-amortissant-bitume-auto-adhesif-400x500mm-p-5408.html

so the advantage of this is that have a lot of density, more than a plaster drywall soo you get a very good insulation with less product, you have a gain of space.

so the beginning and the end of my walls A and C because it is a complete creation of wall have that layers at the beginning and at the end (like in this picture above).

But the wall B and D because they are on a bearing wall, they will have that "sandwich" of layer only at the end.

ps : sorry so much. I'm a little bit ashamed of that maybe to long discussion but the help you gave me is precious and i really want to thank you again. It is the best help i had by reading again all the thread. I have read again all the discussion from the start and now everything is clear, except that point (not very important), it is just to tell you (again because maybe it was not clear) the way i see the walls, not 3 layers of drywall in each part of the wall but drywall/heavy mass/dry wall in each parts of the walls (except the beginning of the walls B and D because the first "mass" is the actual, original bearing wall himself, so i think, if i am not wrong, i don't need for those 2 walls at the beginning because there is the bearing wall, to put layers of drying walls. In other term the bearing wall replaces the first layers of dryingwall that we have at the beginning of the walls A and C because they are a total creation of wall, they are not standing on a bearing wall like walls B and D are.

- And i see also that you said that between each layers of drywall i need to leave 1" space. I really did not knew that. I though all layers can be fixed, glued. I don't understand why there is that space.

- Another important thing you said but i am not sure i read it well, is that for the suspended ceiling i'm gonna do i don't need wool ? But it is better to have only some mass (layers of drywall and heavy mass). So wool is only for the walls ?

- Another important thing you said is that : Between the new walls and the new ceiling, the junction of the two, no need resilience but to seal, the non-hardening caulking (silicone or butyl), the support rod and staggered seams do the job. I thought it can touch each others as you said also but i see that you talked about silicone or butyl to separate them, but i don(t know what it is if you found with google a picture of that product will help me a lot.

I just need to send an email at pac-intl.com to know which susta

I just need to send an email at pac-intl.com to know which sustainer / shrouds can support the maximim of weight and can be fixed at that type of wood frame : https://img.audiofanzine.com/image.php?lang=fr&identifier=image&size=normal&module=user&userPhoto_id=280135

I send above some pictures of sustainers/shrouds, but i saw again the products of pac-intl, and to support the weight of the suspended wall the best is will be the RSIC-WHI. But there is not so much difference with the RSIC-04 series, except that the RSIC-WHI support more weight if i choose the good color, calculate before the weight of the 10m2 suspended ceiling (drywall, heavy mass, etc...). I need to read more but it can be interesting technically to understand why RSIC-WHI can support so much more weight than RSIC-04 ? I'm gonna ask pac-intl.com and the technician that help me because i am curious to know why the RSIC-WHI can support really, so much more weigth ?

So i just need to calculate the weight of my suspended wall to choose which color, which one of the RSIC-WHI is needed. I need to know also with which wires works with the RSIC-WHI (it's in the documentation maybe) and how to fix in the wood boards (this is classic but i don't know and the personn that help me knows that) and more important i want to ask them which thickness wood boards should i use because the shrouds, wires are fixed just under the wood board so even if the RSIC-WHI support weight, the wood frame, boards, needs to support also the weight so maye there is a thickness and kinf of wood to use for those wires and RSIC-WHI shrouds, sustainers. Also for 10m2 ceiling, how far away to each others i need to put them (after calculate the total weight of mu suspended ceiling). All that technical questions i need to see with the technician that help me, and also asking pac-intl.com sending them a picture of the wood frame.

https://www.pac-intl.com/rsic_whi.html

https://www.pac-intl.com/pdf/Installation_Guide_WHI.pdf

Maybe this french product will be ok, i need to calculate, because it doesn't support more than 25 kg.

https://www.acoustique-studio.com/sustainer-p25-10-pieces-c2x9061918

There is a lot of choice for the walls : RSIC-1, RSIC-1 Retro , RSIC-2, RSIC-2 Retro, RSIC-U-HD (i need to read, compare supported weight and everything, and also to see which one goes with the hat tracks, drywall frame channels we have in France). http://www.pac-intl.com/pdf/RSIC-Product-Guide-2014.pdf

http://www.pac-intl.com/pdf/Installation_Guide.pdf

I think you told me something about adding green glue to help them supporting more weigh but i did not understand.

So i have some reading and i will come back few days later just to give the conclusions because i need to read that documentation, i need to translate (with Word Office) and read Rod's book, and i need to talk with the technician help me because i wanted to do my own research before re-talking to him. After all this i will come back because i don't want to bother more, i have some reading book and documentation to do.

But if you have time to see just those last post above, those last note or question it is perfect because it was really by reading everything from the top, the beginning the last things i wanted to talk after.

Best regards.

I think i "advanced". I begin with the things i still hesitant

I think i "advanced".

I begin with the things i still hesitant or have question and after the thing i understood to avoid answer.

1) I start with the things that still not clear or just hesitant :

- More secondary because all options seems close, no much gain, I'm just still hesitant for the floor because a little bit better if possible will be good particularly in that room where the conditions are not the best. I wanted above in my last post give a last time those 4 last options if there is an evolution on your side or if you still for the floor tile with just a carpet under the drum set. I think i will go on your option.

- For the RSIC 1 i will come back maybe later because i need to understand more. For sure we don't have this exact product in France. I searched well, we have only this product below, which unlike RSIC1 have no rubber on it, rubber that can be (i ask ?) all the interest of that product because maybe it is good for vibration and also it creates a little air between wood frame and metal. So maybe those 2 things are essentials, maybe not ? Here is the french product (only thing we have) and it do not fave this rubber thing. I need to read more about RSIC1 but if somebody already understand the difference (that i tried to explain above) between the RSIC 1 and those only products we found in France, it will help me and maybe i can order RSIC1 if better as i tried to described :

https://www.placo.fr/placolog/Produit/PR00022286/Cavalier-Stil-R-F-530

https://www.placo.fr/placolog/Produit/PR00022287/Cavalier-DF-Stil-R-F-530

- For the shrouds of the suspended wall i still also have interrogations because i really see 3 options and it could be different and, except capacity weight, maybe one is better than the other, and for now i try to know if there is an interesting difference or not :

Indeed i see this product, this system shroud that we found in France and note that it is fixed on wood boards from the sides. The only advantages i see is the fact that it is fixed from the sides so you have by the sides more fixations points (if the wood boards are enough thick) and also it is not wires but little metal plate.

https://www.placo.fr/placolog/Produit/PR00023540/Suspente-Maxi-400-Stil-R-F-530

Or totally the same purpose but different is the RSIC-WHI and we don't have it in France (i can order it if it's better) and note that it is not fixed from the sides of the wood boards but from under, and maybe there is less fixation points in contrary of the product above but maybe not (difficult to see if there is multiple fixation points), and to finish it is not a metal plate like the product above but it goes with wires :

https://www.pac-intl.com/pdf/RSIC-WHI_flier.pdf

So i need to clarify this and contact pac-intl.com to know which wires i need with the RSIC-WHI and how it is exactly fix under the wood board (i did not see that), and if there more than one point of fixation in the wood board it could be a good thing. But the advantage of being fixing by under the wood boards is that (maybe) i can have thinner wood boards because i need space, i miss space in high and so when it is fixed from under and not the sides i can maybe have thinner wood boards. I need also to treat the wood against mold and to know what kind of wood and around which thickness wood boards can support the suspended ceiling.

The last option is that product. It is note metal plate like the first product, it is also not wires like the RSIC-WHI, but it goes with hard metal stem that is screwed under the wood boards and so can be fixed only one point of fixation which maybe for wood boards made this product the less interesting of all ? : https://www.acoustique-studio.com/sustainer-p25-10-pieces-c2x9061918

- For the 3 dry wall in each parts of the wall you use (from Rod book i think) i need to think about it because you said that the best is to take 3 layers of dry wall separated by 1" (2.5 cm) space of air one to each other but i though it could be done as described earlier : instead of another drywall in the middle i prefer a layer of heavy mass because it is a very dense material as i described earlier. We can see technical spec here : https://www.audiophonics.fr/images2/5408/Amortson Bi.pdf

And also i am not sure i need air between each layers because in "my system" the air, the "spring" is only in the middle of the walls and it is done by the rock wool (with a 3 cm layer of air only as you told me in further that the rock wool not touching the dry wall plasters). So a have plaster / heavy mass / plaster "sandwich" totally fixed (no air) to each other. It is the first "mass". After the rock wool. It is the "spring". And after again a "sandwich" totally fixed (no air) to each other of have plaster / heavy mass / plaster. I know that you took that from Rod's book but maybe it can be do differently. I see an acoustic engineer next week and i'm gonna ask what he think about those two options.

So you have the same thing but 3 layers of plaster dry wall in each parts of a wall and each one separated by 1".

So for me it fixed like this in this picture, so no 1" air between plaster, and except that i will put as heavy mass as possible between the 2 dry walls (and also the rock wool is not touching the dry walls) : https://prd-mediafolder.s3-eu-west-1.amazonaws.com/h01/h69/8835628564510.jpg

2) And here are the only point i understood i think well to avoid answers on that question if i am right.

Some says that joist tape called also resilient is needed between new walls and new suspended ceiling. You said no. It can touch, so and i don't need resilient/joist tape, but mastic or silicone sticks or backer rod (i prefer silicon stick) can reseal the small space between new walls and new ceiling and under the walls. Perfect, thank you.

Here is the resilient they use in France and they said it is exactly to put between walls and ceiling :

https://www.placo.fr/placolog/Produit/PR00022460/Bande-resiliente-Caroplatre-R-7-en-feutre

What do you think about Green Glue for that job ? For me the Green Glue can be the best option isn't it ?

Again sorry to be here, asking, having those reflections. It maybe can be interesting sometimes in some cases or for some people like me who are "beginners" and interested to understand more before undertake work or giving that work to somebody.

Best regards.

If you go with the suspended ceiling, its a goo idea to go with

If you go with the suspended ceiling, its a goo idea to go with hangers that hold more mass than you intend to start with. This way you can add more if you discover the initial design isnt blocking enough sound.

Insulation for the ceiling rests directly on top of the mass, if there are no ceiling bays.

Im having a bit of a hard time following exactly what you intend for the walls and ceiling, since we've discussed so many options.

To clarify, if you have a wood framed ceiling resting on the new walls, you dont need a suspended ceiling too. Its one or the other. Its just important to verify the suspended ceiling clips or hangers, are allowed for use where the existing drywall is still installed on the ceiling.

I think it would be easier at this point to critique a first draft of your design. Either a drawing or written description or both.

The way i understand it now is:

Ceiling- suspended via hangers

Walls- 4 new walls attach to floor, and existing walls with clips, or new ceiling.

Floor- tile or parquet.

------'

Im not sure if im correctly defining your design.

The closer thing of the RSCI1 is this, it is from the better fre

The closer thing of the RSCI1 is this, it is from the better french company in France but it looks maybe a little bit baddest that the RSIC1 because it look like there is less rubber and they don(t says if like the RSIC 1 it can support 2 boards :

https://www.materiaux-naturels.fr/produit/478-cavalier-anti-vibration-pan-terre

So this french product, very rare, and it look less performing than the RSIC1 because we see clearly a good rubber conception that is separating the structure from the dry walls, the gypsum boards. But if you know where i can order the RSIC 1 because i found this and it is expensive :

https://www.amazon.com/dp/B006UFG1A2/?tag=r06fa-20

Also the RSIC 1 can support 2 dry walls (and it is the product that can support the more layers of dry wall, so forgot about the question about the differences between all of them, the RSIC 1 is the one who support the more weigh), but how do you do when you have 3 dry walls. You put some RSIC 1 between each layers of dry walls ? I think i read (i have to see where) that RSIC 1 can support more than 2 layers of dry walls only if you use more of them, so if there is less separation between them. Maybe in in the documentation or on that video (i will check again). Because it is very important because with the heavy mass i want to put between the 2 layer of dry wall i gonna have some weigh...

(Also in that video i have to understand why they use with the RSIC1 the RSIC-Multi Clip. I think it is the thing they but i did not understood why yet.)

- The RSIC-2 RETRO looks very close to RSIC 1.

- For the suspended ceiling i see that except the RSIC-WHI, i see that the RISC-DC04 series is interesting also. I don't know if there is a reason that i should use more RSIC-WHI than one of the the RISC-DC04 series ? It is not told, written in the documentation, but i think it could be an advantage for the RSIC-WHI because the RSIC-WHI is in the middle of the suspend wall, so maybe the weigh of the dry wall plaster of my new ceiling will be better distributed. I'm really no sure of that. I need to ask specialist in general between those different shrouds for the ceiling (because for the walls it is only the RSIC 1 or the french product above).

Thanks again.

I just saw your answer. Thank you. It's ok i'm gonna see with an

I just saw your answer. Thank you. It's ok i'm gonna see with an acoustic engineer i met if i forgot something in that construction. And i still did not read Rod's book. Don't woory i will see with somebody for the question about the ceiling because maybe a really don't see how to do it.

Indeed as a reminder, i make suspend wall, so i first fix the shrouds directly from the wood board of that kind of wood frame : https://img.audiofanzine.com/image.php?lang=fr&identifier=image&size=normal&module=user&userPhoto_id=280135

But maybe i totally forgot earlier that before fixing the shrouds i need to begin by closing that wood structure with rock wool and plaster just like that :

And in what i explained above it's really not like in those pictures. In what i described above i did not want to do anything on that wood structure, wood frame, wood boards, except putting shrouds on the wood boards at the top to make a 1 leaf mass suspended wall. So like this, i have not a 3 leaf of mass leaf ceiling, which is not good if i remember what you said, but a 2 leaf of mass : my original plaster ceiling and the suspended ceiling.

But maybe i'm totally wring and i need to begin by closing the wood frame like in those last picture above. But if i do that i have 3 leaf : the original ceiling, the wood frame that i close, and my suspended wall.

I don't know if it's clear. If not no problem i will manage this in few days.

- "Insulation for the ceiling rests directly on top of the mass, if there are no ceiling bays." : Yes. That's why i said that in that construction (for the ceiling) i have just one piece of "mass" which is of my suspended ceiling (contain a "sandwich" of dry wall/heavy mass/plaster. So it is a 2 leaf mass.

- "If you go with the suspended ceiling, its a goo idea to go with hangers that hold more mass than you intend to start with. This way you can add more if you discover the initial design isnt blocking enough

sound." : Of course i need to see larger. But as we saw there is different kinds of shrouds that can be fixed on the wood boards (if is like this we need to do...). It can be fixed from under the boards, from the sides. But ok maybe i can forgot that detail because it is not important and just be focused on the weight they can support. That's what you mean i maybe.

- "Im having a bit of a hard time following exactly what you intend for the walls and ceiling, since we've discussed so many options." : Fot the ceiling it is above here. And for the walls i just said that you marhe a separation of 1" air between 3 layers of plaster dry wall, and i just mention the way i will do it : 2 layers of dry wall and not another layer in between but heavy mass (and no air between them). That's the only difference for the walls.

- "To clarify, if you have a wood framed ceiling resting on the new walls, you don"t need a suspended ceiling too" : the wood frame is not resting on anything (that what we talked earlier, it is absolutely

disassociated. So fore sure there maybe something i don(t understood or i was not clear because it is not easy for me in english.

But it is ok. As you said we saw the all the options and so it is just a misunderstanding, something i maybe did not understoot and i will see rod's book and i'm gonna see this acoustic engineer.

Thank you again. I think we went around.

Best regards.

Kyle, I think it would be easier at this point to critique a fi

Kyle,

I think it would be easier at this point to critique a first draft of your design. Either a drawing or written description or both.

You're right, ti is (i hope) really luch easier to understand my interrogation (and i am sorry because i am a beginner). So I made a draw because i am confused a little for the ceiling mostly (but it is the same principal for the walls...so if i understand the ceiling, it is the same for the walls) and for sure there is one of that those 3 options that is the "good" one.

As a reminder all the construction is not resting on actual walls and ceiling, i do not touch to the ceiling and the walls of the room, it is totally dissociated with (that kind) of wood structure, frame fixed in the ground :

Here are the 2 ceiling option construction i thought but i don't know which one is the "good one" ?

http://zupimages.net/viewer.php?id=19/20/90ba.jpg

As you see, in the first little draw, i directly hooking the suspended wall from the wood boards.

But in the second option i first close the wood structure, and after closing it i hook the suspended ceiling from it..

And this third option is really more imposing, more material, but it is maybe the good one :

http://zupimages.net/viewer.php?id=19/20/m31x.jpg

Thank you.

ps : just a detail, note that between 2 layers of dry wall, some put another layer of drywall (so 3 dry wall) and it is what you told me, but i would prefer having heavy mass (very high density kg/m2 for less thickness than dry wall) between 2 dry wall layers : https://www.audiophonics.fr/fr/amortissants/pinta-amortson-bi10a-phd-amortissant-bitume-auto-adhesif-400x500mm-p-5408.html

So of course in draws 2 and 3 (because it was difficult to draw)

So of course in draws 2 and 3 (because it was difficult to draw) i fill the bays of the wood frame like one of those pictures :

Ok so i think i understand. As long as: 1. the rockwool goes

Ok so i think i understand.

As long as:

1. the rockwool goes in the bays of the wood framing

2. The wood framing is 1" spaced from existing room

3. The mass is attached directly to the framing.

All appears to be good! What your building is a true "room-in-room". This offers the best isolation, and the lowest cost. Excellent. In this method there is no need for clips.

There are some basic details as far as caulking the seams, and staggering the edges at the corners, which will ensure airtight construction.

It is also very important to plan on your wiring for both audio and electrical. It is often possible to hide the wiring behind your acoustic treatment.

At this point it makes sense to plan on the room layout, the basic acoustic treatment, and the wiring.

Doing this will help identify areas that need special attention.

Thank you very much. - "1. the rockwool goes in the bays of the

Thank you very much.

- "1. the rockwool goes in the bays of the wood framing" : Yest of course. My dray was just like a little bit "inverted"... because the rock wool in the draw wasn't going in the direction of the wood boards... so of course the wool gonna be in the bays (my draws were inverted...).

- "2. The wood framing is 1" spaced from existing room" : Yes of course, i remember you told me that important information before (it is minimum 2.5 or 3 cm spaced form existing room).

- "3. The mass is attached directly to the framing" : I checked my draw again and there are errors. I need to do it again but i will check with a specialist because i am confused on those possibilities : there are 1 mass possibilities, 2 mass possibilities... I will just do the draws better again because it is not good, i saw gross errors. Really sorry.

- Another thing, for sure i will not use rock wool but regular wood, glass wool (the pink in us) because for the "spring" it is not density that is important, but a low AFR Resistance Air Flow, AFR.

I saw gross errors on placing rods/wires, rail maybe and of cour

I saw gross errors on placing rods/wires, rail maybe and of course sustainers on my draws (or i could do it differently), i did it late in the evening, and also of course i am not a specialist in assemblies, etc... and because i'll of course do the job with a specialist in construction work, the only thing important for me right now is just to understand the mains possibilities in terms of layers of mass and spring, etc..., the principal.

Indeed to be precise my principal and only interrogation, the very main question in those ceiling possibilities is that to do simple, i don't know if i just need to close simply the wood frame with wool in the bays and rail/dry wall/heavy mass/dry wall and it is just finished (like in little the first draw even if i did not correctly) or it is more like the draws 2 and 3 where i have a first ceiling that i close directly with wool/rail/dry wall/heavy mass/dry wall but after that i make another suspended ceiling with exactly the same assemblies wool/rail/dry wall/heavy mass/dry wall.

You said it is all good but for sure it is different. Number 2 and 3 gives i think the best insulation but maybe don't do that in construction, and only do a simple closig a little but like the first draw wait wool in the bays and rail/dry wall/heavy mass/dry wall to close. But i think it is less insulation that closing like that ok, but after doing it again so you get 2 times spring and 2 times mass.

Thank you.

jerem1, post: 461111, member: 51587 wrote: You said it is all go

jerem1, post: 461111, member: 51587 wrote: You said it is all good but for sure it is different. Number 2 and 3 gives i think the best insulation but maybe don't do that in construction, and only do a simple closig a little but like the first draw wait wool in the bays and rail/dry wall/heavy mass/dry wall to close. But i think it is less insulation that closing like that ok, but after doing it again so you get 2 times spring and 2 times mass.

You dont need anything more than an independent wood frame, mass, and the insulation. Adding additional rails, and springs. Doing so would add leafs to tbe system. Once you decouple the framing, you want all your mass attached dirctly to that.

The principal behind this is called the mass law. Each time you double the mass, you cut the sound in half (roughly 10db).

So 2x layers is 10db.

Next 2x layers is 10db.

Then you need to add another 4x layers for the next 10db.

Then add another 8x layers! For the next 10db. This means 16x layers.

(I understand the mass law can be a bit confusing)

You want as much mass as possible attached to your isolation layer. And you want 2 leafs, or as few leaves as possible.

Thank you very much Kyle. Trust me it is absolutely finish and i

Thank you very much Kyle. Trust me it is absolutely finish and i am sorry and thank you again for this time you took, help you gave, it really allowed me to understand the last things i wanted to understand.

Also those very few, but good videos above here (in "chapter 2)"), helped me also by showing very well the construction and details (clips like "RSIC1", hat channel, sealant between dry walls, under and at the top, dry walls in cross, and more). Of course all of this gonna just help me just to discuss with the technician, to be sure we do the best as we can.

1) First of all i have no more question about the ceiling or the walls (except q little one above). I perfectly understood that the first one of my draws was the "good one", the closer one of what i need to do, because there is one leaf "mass" (we do not count of course, as said before, the original ceiling of the room because it is decoupled and does not fit into the discussion).

Indeed I had to ask again about those 2 or 3 draws i did because the first time you told me that all where goods but i remember that problem of multiplying "mass" layers, the "double mass" law. In that two last draws indeed, after closing the wood frame with wool/rail/dry wall/heavy mass/dry wall there was once again another layer of wool/rail/dry wall/heavy mass/dry wall,. So the two last draw were really not what i needed to do as you just said above because it creates a double leaf which is cutting the sound. So just one leaf of "mass".

It is very clear now, i will go for a simple thing like the first draw, so a simple leaf mass which consists by closing the wood frame with wool in the bays/dry wall/heavy mass/dry wall (i will see the details with the technician).

(I note also that with a simple one mass layer ceiling, it gonna be possible to add more "spring", more wool.)

So the ceiling gonna be very close to this (with the shrouds appropriate in weight capacities to maintain all of this) : wood frame (decoupled, not touching the existing room ceiling with minimum 1" separation)/ 10 to 15 cm of wool in the bays of that wood frame / RSIC 1 (or equivalent) screwed to the wood frame / Hat channel into the RSIC1 / dry wall/heavy mass/dry wall directly (all together is 4 cm of mass) screwed to hat channel.

I forgot, very important, i think i will put 10 or 15 cm of wool in that ceiling (i can't put more). Do you think it is a good proportion, quantity of wool ? 42mm, so 4,2 cm of "mass" (dry wall 19 mm /heavy mass 10 mm /dry wall 13 mm) does it seems ok ? If needed or a possibility to put more mass please tell me because it is a drumset ? So 15 cm wool + 4.2 cm mass it is around 20 cm new ceiling, should it be enough ? If no i don't know how it could be better because i have to respect that 1 "leaf of mass" in my new ceiling as you said.

2) So to finish (again i really did the round, i have every thing to talk with the technician : pictures, videos, main products) but there is that only 2 things i wanted to tackle to finish.

By seeing this picture (took from a video) i see that, in classical insulation construction (in France), wool is very stuck ,tight to the dry walls and maybe it could be not the best thing for insulation. I need to see that with the technician, i need to see if we have something like the hat channel because indeed as we see in that video, the hat channel allows to not stuck the dry walls to the wool. I just wanted to know if it is a big problem if we do the "french" classical way. Of course if we have hat channel like you we gonna use it but this picture show that it is more "traditional" what should maybe worries me little ? But if there is not hat channel, we have no choice, we will do without.

Here is the "classic" way, wool stuck to dry wall (simple channel in between) : http://zupimages.net/viewer.php?id=19/21/sgoq.png

Here is very short video (i did and recording) showing the same thing with hat channel (so air, space between wool and dry walls thanks to hat channel) : https://streamable.com/935oo

(They say also that that product can carry 3 dry walls, in contrary of RSIC 1 that can carry 2 boards)

And the last thing, a little bit in the same idea, do you think the rubber "thing" in RSIC 1 is very important because i understand that i can maybe mitigate vibrations, because of this rubber in between the metal of the RSCI 1 and the wood frame ? I found also clips without that rubber but i will use rubber ones (but more expansive that's why i ask) because in the second video above they says "it dramatically reduce sounds transmissions".

(I'm note sure if i need to use an acoustic sealant like the GG sealant or another classic acrylic sealant, but i will see)

(To finish not by a commentary or a question, i just put above 2 videos that i find clear and short. Note that in those videos they use heavy mass called "techsound" between the dry walls boards as i wanted to do) :

Thank you.

As a reminder the height of the room is 2.15 meter that's why i

As a reminder the height of the room is 2.15 meter that's why i can't do not more than 20 cm ceiling. Even if it is not enough and perfect i need to do it. So if you Kyle are used to see and build studios, with the the precise information that i put above, maybe you have a feeling it that should provide me a good isolation for the ceiling ? I'm not playing very high level music, not playing also on big drum set (medium or small), but just sometimes i hit little bit harder.

Also but not very important information but good to say, the 19mm dry wall got a thin layer of sound proofing material in it, and the 13 mm dry wall is a special phonic drywall.

As a reminder also the existing ceiling of the room (even if is disassociated from the new structure and new ceiling of course) is not a very strong one because as we can see (in this draw again) it is composed by 3cm of parquet (neighbors), wood joists under the parquet, and under the joists it's 25 cm full of plaster, in the bays it is 8 cm plaster with 17 cm air above (so it does some kind of waves of plaster) : http://zupimages.net/viewer.php?id=19/19/zeu5.jpg

For sure i am gonna screw some heavy mass boards to this existing room ceiling (even if of course it is disassociated from the new structure and new ceiling), because it will take only very little height under ceiling (thin plates of 5mm), reassure me a lot also, and i will see with the technician how much mass he thinks that existing ceiling can support ?

So simply i hope with all that : add heavy mass to the existing ceiling, create a disassociated wood frame / put 10 to 15 cm of wool in the bays / acoustic dry wall 19 mm / heavy mass 5 or 10 mm if possible / acoustic dry wall 13 mm, will finally be enough insulation for a drum set ? When you never build a studio before it is indeed difficult, almost impossible to have an opinion, imagine what level of insulation it can provide if i do simply like this.

I thought maybe i can put less wool and the so i will be able to put another layer but thinner layer wool and "mass" again (so like in draws 2 and 3, less wool in further to double another time another floor of wool and "mass") , but you told me that even if it seems strange and confusing, it is a double layer of mass which is not good (law of mass), so i see i have no other options that doing like above except if you see an option but i guess it simply what to do.

I note that in that "simple layer mass" ceiling : create a disas

I note that in that "simple layer mass" ceiling : create a disassociated wood frame / put 10 to 15 cm of wool in the bays / acoustic dry wall 19 mm / heavy mass 5 or 10 mm / acoustic dry wall 13 mm. We have not a mass-spring-mass system but only spring - mass, except if you count the existing room ceiling as the first mass. If you count the ceiling, yes it is exactly a mass-spring-mass system.

Sorry, i am ashamed to insist, but i really need to be sure.

jerem1, post: 461125, member: 51587 wrote: So the ceiling gonna

jerem1, post: 461125, member: 51587 wrote: So the ceiling gonna be very close to this (with the shrouds appropriate in weight capacities to maintain all of this) : wood frame (decoupled, not touching the existing room ceiling with minimum 1" separation)/ 10 to 15 cm of wool in the bays of that wood frame / RSIC 1 (or equivalent) screwed to the wood frame / Hat channel into the RSIC1 / dry wall/heavy mass/dry wall directly (all together is 4 cm of mass) screwed to hat channel.

There is no need for clips and channel when you have an independent wood frame. Clip systems are only for attaching to existing construction.

The air space between the existing structure and wood frame is the "spring".

The wood frame holds more mass than the clips could. You'd be reducing your isolation with the clips, and increasing cost significantly.

jerem1, post: 461125, member: 51587 wrote: I forgot, very important, i think i will put 10 or 15 cm of wool in that ceiling (i can't put more). Do you think it is a good proportion, quantity of wool ? 42mm, so 4,2 cm of "mass" (dry wall 19 mm /heavy mass 10 mm /dry wall 13 mm) does it seems ok ? If needed or a possibility to put more mass please tell me because it is a drumset ? So 15 cm wool + 4.2 cm mass it is around 20 cm new ceiling, should it be enough ? If no i don't know how it could be better because i have to respect that 1 "leaf of mass" in my new ceiling as you said.

You want the standard thickness of "classic" insulation that fits into the wood frame.

Save the rockwool for the acoustic treatments.

jerem1, post: 461125, member: 51587 wrote: . I just wanted to know if it is a big problem if we do the "french" classical way. Of course if we have hat channel like you we gonna use it but this picture show that it is more "traditional" what should maybe worries me little ? But if there is not hat channel, we have no choice, we will do without.

No problem. Insulation offers very little isolation.

Most likely you'll have 2x4 wall studs, and a 2x6 or 2x8 ceiling joists. This depends on the ceiling span.

jerem1, post: 461125, member: 51587 wrote: I'm note sure if i need to use an acoustic sealant like the GG sealant or another classic acrylic sealant, but i will see)

GG is only for increasing isolation between mass.

For sealing use a standard Non-Hardening SILICONE, or BUTYL caulking.

Acrylic will crack over time because it hardens fully.

jerem1, post: 461126, member: 51587 wrote: As a reminder the height of the room is 2.15 meter that's why i can't do not more than 20 cm ceiling. Even if it is not enough and perfect i need to do it. So if you Kyle are used to see and build studios, with the the precise information that i put above, maybe you have a feeling it that should provide me a good isolation for the ceiling ? I'm not playing very high level music, not playing also on big drum set (medium or small), but just sometimes i hit little bit harder.

A 2x6 ceiling joist, with 3 layers of 5/8 drywall, with GG in between equals 5x layers of drywall, which is good.

Having no DB level of your drums to go off of its tough to estimate.

Also since your existing assembly and your new one doesnt have specific test data its not easy to estimate.

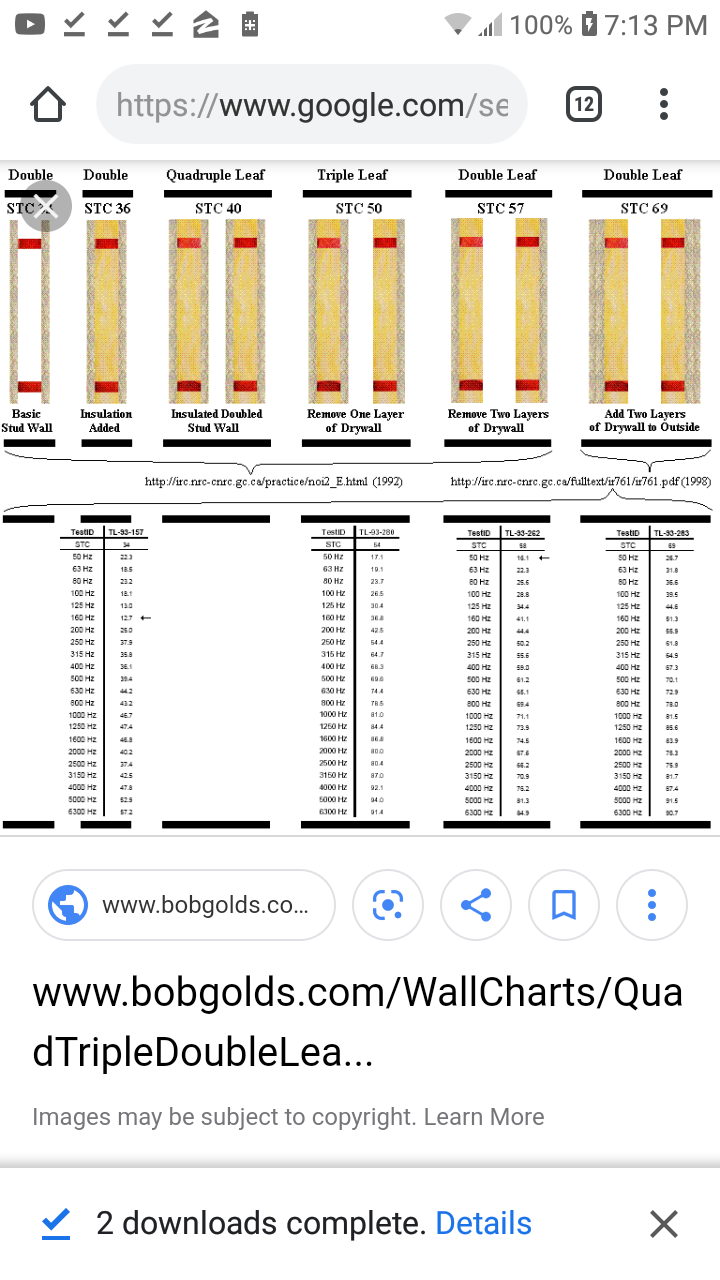

Based on the additional mass and the chart your looking at something around STC 65, with your existing ceiling, decoupled wood frame and 3x layers drywall + GG.

This is equal to a standard double wall with 2x layers each side.

Will it be enough? It really depends on whats directly above you. If its a quiet office, then you could have issues. If its a loud kitchen or retail store playing music on a system, you should be ok.

To give expample.

One studio i built has the a STC 65 type wall between drum room and control room, with the kit 3 meters away from control room. No sound bleeds between room, dead silence.

The booth next to the drum room also has an STC 65 wall between them, but the kit is less 1 meter away than the booth. The kit can be heard by ear in the booth, but doesnt get heard by the mics. Part of the reason is the door isnt as thick as the walls, the other is how close the kit is to the room.

I measured a 45DB reduction in sound with a sound meter, between the booth and drum room, measured 1 meter away. STC ratings are based on 1 kilhertz frequency. So they tell you how many DBs get blocked at 1k. This is how a STC 65 wall can only block 45DB full range, even when buit properly.

So to give a very, very general estimate Your looking at blocking 45-50db. So if your drums are quiet at 100db, then you block 50db, there's roughly 50db of bleed into the upstairs.

jerem1, post: 461126, member: 51587 wrote: Also but not very important information but good to say, the 19mm dry wall got a thin layer of sound proofing material in it, and the 13 mm dry wall is a special phonic drywall.

Make sure you check the test data for this, and that it is worth any additional cost. Often standard drywall is preferred over "quietrock" and other specialty drywalls. Bur if space is tight it might make sense.

jerem1, post: 461126, member: 51587 wrote: So simply i hope with all that : add heavy mass to the existing ceiling, create a disassociated wood frame / put 10 to 15 cm of wool in the bays / acoustic dry wall 19 mm / heavy mass 5 or 10 mm if possible / acoustic dry wall 13 mm, will finally be enough insulation for a drum set ? When you never build a studio before it is indeed difficult, almost impossible to have an opinion, imagine what level of insulation it can provide if i do simply like this.

Insulation is whatever fits into the bays. I would consider using only the thickest drywall for each layer. So 19mm only, no 13mm.

jerem1, post: 461126, member: 51587 wrote: I thought maybe i can put less wool and the so i will be able to put another layer but thinner layer wool and "mass" again (so like in draws 2 and 3, less wool in further to double another time another floor of wool and "mass") , but you told me that even if it seems strange and confusing, it is a double layer of mass which is not good (law of mass), so i see i have no other options that doing like above except if you see an option but i guess it simply what to do.

You want the insulation in the frame, and all drywall layers attached to the frame. Just like the drawings in rods book.

jerem1, post: 461129, member: 51587 wrote: I note that in that "simple layer mass" ceiling : create a disassociated wood frame / put 10 to 15 cm of wool in the bays / acoustic dry wall 19 mm / heavy mass 5 or 10 mm / acoustic dry wall 13 mm. We have not a mass-spring-mass system but only spring - mass, except if you count the existing room ceiling as the first mass. If you count the ceiling, yes it is exactly a mass-spring-mass system.

The existing ceiling counts.

Thank you for all these useful details. There is no need for cl

Thank you for all these useful details.

There is no need for clips and channel when you have an independent wood frame. Clip systems are only for attaching to existing construction. The wood frame holds more mass than the clips could. You'd be reducing your isolation with the clips, and increasing cost significantly.

So i understand that : i don't need that hat channel that creates space between wool + wood structure and dry wall, a "simple" channel (even if it doesn't create that air space wool + wood structure and dry wall like hat channel) will do the job. So wood frame + wool in it will be very close to each other, nor air in between likes does hat channel).

So also simple clips can carry the "simple" channel will be ok, i don't need also rubber clips. Just take care a little bit that the clips can carry my layers of "mass" but it is no so important because it is mostly the wood structure that carry it.

So if i understand, but i will see the technician, it may be even possible to have no channel and no clips (clips carry th , because the mass can be screwed directly to wood structure.

I'm not used to constructions of course but by reading you i see that it quite simple, a simple channel and simple clips (channel goes into the clips) can be used and maybe the technician would like to

The air space between the existing structure and wood frame is the "spring".

Yes to be exact there is minimum 1" air between that existing walls and ceiling and the wood structure and in the wood structure the wool. So all of that is the spring (even if there is of course some wood with the wood frame).

Thank you for all these useful details and opinion. There is no

Thank you for all these useful details and opinion.

There is no need for clips and channel when you have an independent wood frame. Clip systems are only for attaching to existing construction. The wood frame holds more mass than the clips could. You'd be reducing your isolation with the clips, and increasing cost significantly.

I don't understand why because i thought that no matter if you build a wood frame separate of the existing structure or a wood frame fixed to the existing walls like the 2 videos above, it is in my mind absolutely the same need of using channel and clips. But you say that i don't need either channel or clips when the wood frame is separate from the existing wall.

And by the way so there to i don't need that hat channel that creates space between wool + wood structure and dry wall, a "simple" channel (even if it doesn't create that air space wool + wood structure and dry wall like hat channel) will do the job. So wood frame + wool in it will be very close to each other, no need air in between likes does hat channel.

So also simple clips can carry the "simple" channel will be ok, i don't need also rubber clips. Just take care a little bit that the clips can carry my layers of "mass" but it is no so important because it is mostly the wood structure that carry it.

More than than that if i understood you, it may be even possible to have no channel and no clips (clips carry the channel and the screws are going into the channel) , because the mass can be screwed directly to wood structure.

So what is important here is that first i have no obligation to use hat channel that create that air space, no special clips also, and maybe also i don't need either channel or clips (i need to see with the technician if he can do without clips and channel and screw the mass directly in the wood frame.

The air space between the existing structure and wood frame is the "spring".

Yes, to be exact there is minimum 1" air between that existing walls and ceiling and the wood structure with the wool in it, all of that, 1" air minimum + the wool is the spring (even if there is of course some wood with the wood frame).

You want the standard thickness of "classic" insulation that fits into the wood frame. Save the rockwool for the acoustic treatments.

I called yesterday a technician of the wool company and he was very patient and interesting and he exactly told me what you said. It is a kind of funny coincidence. He clearly told me that for my insulation the mass is the most important and the spring will have very less effect on insulation and absorption because when a wool is placed between well closed dry walls, the wool as a very insignificant effect on insulation and absorption. All the test they did went to this conclusion. And he told me that in contrary when the wool is used inside the room (not in between to well close walls) or in a wall but with micro-perforated boards, that is the case where wool can have impact, effect.

But for me and it is normal to think about the quantity of spring because more spring there is, more further i am from the rooms or neighbors where i don't want to see my sound going. So in further of that i will see the amount of wool i will put, they have classical layer of 100 mm or 140 mm so for sure it will be one of those. So 140 mm will be better no because of the wool (not very much effect himself into 2 "mass"on insulation or absorption), but because it creates of course more space with 140 mm than 100 mm between me and the others rooms where i try my sound to not (or less as possible) go in.

I could go for 140 mm to do the most i can for "insulation", isolation, creating more space between and neighbors upstairs, or 100mm so it will give more space for treatment inside the room, and having a bigger room sound as well for recording. It is a difficult choice and i will go to do the maximum to protect neighbors in despite of the quality of the sound inside (because less "room sound" with low level ceiling). There is a little choice here. Maybe it is really more intelligent to do 100 mm because the treatment inside will have an effect as well a little bit in insulation and for the qualities of the room.

Also putting less wool will give me to add more mass as i talk below. But i still need to respect i think 40 to 60% of wool, so half of the wall or ceiling which is easy to respect eveven with a lot of mass.

I don't ask an answer because there is so more choices and all are ok but if you have an advice, i will of course take it. Finally i think more to put about 100 mm to have a better room sound, and maybe like that will be goof for more room treatment inside (which maybe could have by the way a also a very little impact on the outside because the sound is better inside).

For sealing use a standard Non-Hardening SILICONE, or BUTYL caulking. Acrylic will crack over time because it hardens fully.

i thought that acrylic was more for dry walls because silicon is more for wet rooms. But if you say Silicon is better i trust you.

A 2x6 ceiling joist, with 3 layers of 5/8 drywall, with GG in between equals 5x layers of drywall, which is good.

I wanted to put heavy mass between 2 dry walls. But because you told me above that the wood structure will be mostly carry the "mass" and i can also do the job without clips and channel, it is really more interesting if i can do like this because without clips that can carry more than a certain weight, if the wood structure carry the weight and if we put a lot of attention on the quality of that wood frame to carry the weight, and also the shrouds (the best shrouds i saw are the RSIC-WHI, or equivalent in France if there is), i can do more than i thought. It is a very important point, i want to do the best for the mass of the ceiling. So with the wood frame appropriate and the shrouds appropriate, i could maybe for the mass of the ceiling, do it will be perfect, 3 dry walls, heavy mass between the 2 dry walls, but for the GG between all of them i don't think i will go for it because even if it "adds dry walls", "mass", it is to expansive (need to put 2 sticks for each dry walls, so for the ceiling and for the 4 walls...).

Because i really want to put heavy mass every time between 2 dry walls (like in the videos above) because heavy mass is 10kg/m2 (good for mass) if i put GG every time between heavy mass and dry wall boards and for walls and ceiling it gonna be very expansive. dry wall + GG / heavy mass + GG / dry wall + GG / heavy mass + GG / dry wall at the end. So it does a lot of GG...

But because the ceiling is the most important isolation, insulation i need to care of (neighbors only upstairs) i thing i'm gonna use GG only for the ceiling and exactly as aboce : dry wall + GG / heavy mass + GG / dry wall + GG / heavy mass + GG / dry wall at the end

In the same idea if i want to reduce and optimize the use of the GG, for the walls, i can use it only for the last layer (the last layer close to my studio) between heavy mass and dry wall.

So if as you said it can be possible to directly screw at the wood structure (walls or ceiling), but of course with the shrouds appropriate for the ceiling, so it will be possible to add more "mass" than i thought, and less wool as explain above because it as a low effect on isolation, insulation between to well close walls. So i reduce wool to add more mass because it is the most important, effective.

Thank you for the STC 65 examples, it gave me an impression. As just said above i could also maybe do a little bit better that i thought with dry wall / heavy mass / dry wall / heavy mass + GG / dry wall at the end. So i will put one more layer of mass and dry wall and GG at the end of walls and ceiling (so the layers the most closer to the drum set). I was hesitant for GG but i will follow you. It seems a better product that i thought, and i will try to use at least at the end of the walls and ceiling like above, so a good compromise between not using GG at all, or using GG where it can be the most effective (i would like to use it between all layers, between all boards heavy mass/dry wall, but it gonna to expansive.

I would consider using only the thickest drywall for each layer. So 19mm only, no 13mm.

Very good idea also. Because i will have less wool like explain above, i will have more space for "mass". Instead 19mm dry wall and 13 mm, i will use 25 mm the biggest kind) and 19 mm (both acoustic type). And all the time heavy mass in between. If the wood frame (and shrouds/hangers for the ceiling) are chosen in further to carry all that weight, it is really the best i can do. I heard also that is good for frequencies, diffraction, or something like this, i don't remember exactly the term, to use if possible different thickness of dry wall and for sure i will use different thickness.

So it can be for walls and ceiling, just for the mass part (and with GG at the end between the 2 lats layers) : dry wall 25 cm / heavy mass / dry wall 19 cm / heavy mass / dry wall 19 again. So i close the room with, the last dry wall in the room is a 19 cm.

Or it is interesting to note that it can maybe do (?) because it could be better the exact opposite, conversely : dry wall 19 cm / heavy mass / dry wall 19 cm / heavy mass / dry wall 25 again. So in that case the bigger dry wall is at the end, in the room.

Or intermediate : dry wall 19 cm / heavy mass / dry wall 25 cm / heavy mass / dry wall 19 again.

So there are also the exactly the same options with 2 layers of 25 mm and 1 layers of 19. If i have the space to do it.

What can be interesting to know here, is if we could be a more effective solution, formula, arrangement : put the thicker layer of dry wall at the beginning of the "mass", in the middle, or at the end, close to the studio, the drums, the sound. Maybe it can do is a difference, maybe not, i have absolutely no idea. I don't ask really the question because all will be ok but it can be interesting to know when there is 2 thickness of dry walls and 3 layers of dry wall.

Also you said 2"x6" ceiling joist wood can carry 3 layers of dry walls. Maybe we will need to have bigger joists for the "mass" i described above.

- All the rest is very very clear. So above just some commentary and new ideas, progressions.

jerem1, post: 461134, member: 51587 wrote: I don't understand wh

jerem1, post: 461134, member: 51587 wrote: I don't understand why because i thought that no matter if you build a wood frame separate of the existing structure or a wood frame fixed to the existing walls like the 2 videos above, it is in my mind absolutely the same need of using channel and clips. But you say that i don't need either channel or clips when the wood frame is separate from the existing wall.

The wood frame doesnt touch the existing structure. This gives you mass-air-mass. The air is the "spring".

jerem1, post: 461134, member: 51587 wrote: So also simple clips can carry the "simple" channel will be ok, i don't need also rubber clips. Just take care a little bit that the clips can carry my layers of "mass" but it is no so important because it is mostly the wood structure that carry it.

No clips necessary with decoupled wood frame.

jerem1, post: 461134, member: 51587 wrote: More than than that if i understood you, it may be even possible to have no channel and no clips (clips carry the channel and the screws are going into the channel) , because the mass can be screwed directly to wood structure.

Correct!!

jerem1, post: 461134, member: 51587 wrote: So what is important here is that first i have no obligation to use hat channel that create that air space, no special clips also, and maybe also i don't need either channel or clips (i need to see with the technician if he can do without clips and channel and screw the mass directly in the wood frame.

Clips and channel are not necessary. A decoupled wood frame gives the best isolation possible.

jerem1, post: 461134, member: 51587 wrote: Yes, to be exact there is minimum 1" air between that existing walls and ceiling and the wood structure with the wool in it, all of that, 1" air minimum + the wool is the spring (even if there is of course some wood with the wood frame).

Airspace is the "Spring".

The insulation is a "dampening" entity. Like tea towels, or moon gels on a drumhead.

jerem1, post: 461134, member: 51587 wrote: I could go for 140 mm to do the most i can for "insulation", isolation, creating more space between and neighbors upstairs, or 100mm so it will give more space for treatment inside the room, and having a bigger room sound as well for recording. It is a difficult choice and i will go to do the maximum to protect neighbors in despite of the quality of the sound inside (because less "room sound" with low level ceiling). There is a little choice here. Maybe it is really more intelligent to do 100 mm because the treatment inside will have an effect as well a little bit in insulation and for the qualities of the room.

Use the standard thickness insulation for your walls and ceiling joist size.

jerem1, post: 461134, member: 51587 wrote: i thought that acrylic was more for dry walls because silicon is more for wet rooms. But if you say Silicon is better i trust you.

Rod told me to use silicone...

jerem1, post: 461134, member: 51587 wrote: but for the GG between all of them i don't think i will go for it because even if it "adds dry walls", "mass", it is to expansive (need to put 2 sticks for each dry walls, so for the ceiling and for the 4 walls...).

Look into bulk GG and caulking. Buying by the small tube adds up fast. You can get caulking in a large bucket, and GG as well, last time i checked a few years back.

jerem1, post: 461134, member: 51587 wrote: But because the ceiling is the most important isolation, insulation i need to care of (neighbors only upstairs) i thing i'm gonna use GG only for the ceiling and exactly as aboce : dry wall + GG / heavy mass + GG / dry wall + GG / heavy mass + GG / dry wall at the end

Make sure you verify GG is even tested use between "heavy mass" layers. Ive only seen testing for its use in drywall, that i can recall.

jerem1, post: 461134, member: 51587 wrote: Or it is interesting to note that it can maybe do (?) because it could be better the exact opposite, conversely : dry wall 19 cm / heavy mass / dry wall 19 cm / heavy mass / dry wall 25 again. So in that case the bigger dry wall is at

I woud use all 25cm for each layer.

The order of the drywall and mass does not matter. Its functioning as one unit.

jerem1, post: 461134, member: 51587 wrote: Also you said 2"x6" ceiling joist wood can carry 3 layers of dry walls. Maybe we will need to have bigger joists for the "mass" i described above.

The amount of load (drywall) depends on the span the joist.

1. figure the span

2. Check the smallest joist rated for the span

3. Check that joists load bearing capacity

4. Compare that with your intended mass.

5. Remember screws, lighting, wires, caulking, glue, acoustic treatments, and the Joists themselves count as the load / mass

A structural engineer is reccomend to sign off on the final design. There are plenty of charts online which help architects plan such things.

Thank you very much. The wood frame doesnt touch the existing s

Thank you very much.

The wood frame doesnt touch the existing structure. This gives you mass-air-mass. The air is the "spring".

I understand that i have the choice to just leave air in the wood frame. But i prefer adding some wool because i heard that it is always better to put a wool than nothing/air, but maybe not, because if i reed you and what told me the technician of the company ("with the same thickness of "spring" and 2 well close mass at each parts of the walls the type of the wool will be insignificant", after laboratory test). So with the same thickness "spring", if the kind of wool have no impact, we can also maybe conclude by extension that, with same conditions, same thickness of "spring" and 2 well close mass at each part of the walls, between air and when the wall there will be no effect on insulation, isolation, or absorption. But the test they did was between different wools and no between wool and air but maybe it will do the same, and for sure i guess very less effect.

So i will see what i am gonna do. Nothing in the wood frame or little bit of wool because it reassures me, and furthermore it doesn't take space because it is in the wood frame. I guess there is always a little bit of sound that crosses the first layer of mass, so wool can have a maybe minimum "dampening" insulation, isolation impact and i will take that little chance. Also wool is good for thermal insulation i guess.

So if as he told me the kind of wool have no effect (no matter level of AFR, Resistance Air Flow) when same thickness and 2 layers of mass are to the extremities of the wall or ceiling, i think it can be interesting to go on rockwool 70kg/m3, not for absorption (no effect as said...) but to add a little bit more "mass", even if it is nothing in term of mass comparatively to the heavy mass (10kg/m2) and dry walls. So that rock wool is still spring comparatively to the "mass" at each parts of the walls (and ceiling), but it just add a little bit of mass. Maybe it is very little more insulation comparatively to air, but i will take that chance.

Use the standard thickness insulation for your walls and ceiling joist size.

Yes, the wool gonna be in the wood frame and in the "bays" of the wood frame ceiling and gonna be around the thickness of the wood frame. For the ceiling for sure in don't want to put the wool on the wood frame but in the wood frame, in the "bays" because if i put it on i am gonna loose some height. So as you said above the 1" separation + the frame himself gonna be the spring and if i put some wool it gonna be only in the wood frame.

Here is a very detail, no need to answer : i will also see with the technician (even if just air will be ok) how to maintain the wool in the frame (maybe some normal kinds of wires are needed, maybe some thin metal channel) because in that decoupled wood frame there is nothing in the side between the existing wall and the wood frame so i don't want the wool to "fall" into that 1" space (indeed it is not the case of the videos where the wood frame is"glued" to the existing walls, the wool is easily in place because it is stuck to the existing wall). It is a detail and also i can do without any wool, but i will see that because it is just interesting to know how the wool can stand, maintain in place with a decoupled wood frame. For the ceiling i guess we have some thin channels under the wood frame to maintain the wool who is in the frame, and for the walls also and the thin channel (or wires) are in both sides of the wood frame to maintain wool in the frame (and of course in the frame we have some wood boards doing some squares in the wood frame to pose the wood on them + wires or thin metal channel to maintain it). Short, it is just a detail, i will see with him.

...

All the rest is also clear.

Thank you very much also because i understood (i think) that channel and clips are no used for assembly requirements as i thought, but for adding some air, spring and also make a decoupling between wood frame+wool, and mass. So if i understand in those videos they do a not between the existing wall and the wood frame, but between the wood frame and the mass, thanks to the channel and clips. So i don't understand why they don't just do a decoupled wood frame directly as i do. Maybe they don't know in those 2 videos that it is de the best option to decoupled before and not after as they do with channels and clips.

So maybe they do like to because they "don't know that the best solution is to make a decoupling before the wood frame and not after (with the channel and clips). So i understood that those channel and clips are no here for needs construction but to create more space, spring and also have a decoupling between wood structure and mass, but it could be better to make that decouplation as you suggest me, between existing wall and wood frame.

I will see for the large bucket of GG and for the GG with heavy mass (i can send an email to the company) because i also saw that it was between 2 dry walls.

The 25cm for each layer is a great idea ! I hope we can make a wood frame and found shrouds that can support 3 time 25 cm dry walls + heavy mass in between each layers of dry walls.

I will see with the technician because it is also a detail in construction, that if the wood frame is enough strong, maybe we don't need shrouds for the ceiling and can screw all the mass directly to the wood frame, but i do not think there is enough long screws to do that, so maybe shrouds with channel will be needed and also because i will reinforce the capacity of the wood frame to carry the mass.