dvdhawk - I'm starting a new thread with details on the proposed ICF building project. Here's the background information our moderators like.

Location: Western PA -USA

If you looked at a satellite photo of my location you would see all the forests and farmland, and you might think that outside -> inside noise wouldn’t be much of a problem in such a rural setting. Not true. We just have different problems than the suburbs and cities. We’re in the middle of a small cluster of homes along one of PA’s primary 2-lane roadways and we’re just 1/2 mile from Interstate-80. We’ve got great neighbors and we all try to be respectful and not make too much racket, early or late. I personally don’t need much volume to be happy and I’m much more likely to pick up an acoustic guitar or play an unplugged electric. But due to some unresolved karmic debt from a past life, my son plays drums. Thankfully he’s not a basher, but still, a 16 yr. old drummer playing the kind of music 16 yr. olds and his friends would play. (on the loud side) I own no less than 3 decibel meters, and have never measured the dBs inside or out when he's playing. I’d have to guess 95-100 dB inside would be the maximum inside level.

Project Description:

Multi-Function 55’ x 32’ Multi-Level Building attached to existing home.

Goals of the entire building project:

To make the most sound-proof and energy-efficient building possible on a reasonable budget.

2-car Garage with Workspace and Storage.

Recording and Production Space for my solo projects, band projects, and my 16-yr. old son’s band(s)

Production Space for occasional outside recording projects, and A/V post-production.

Control Room that can double as client-friendly Video Screening Room

Rehearsal Space for me and my son’s bands ( they practice a lot more than us old guys )

Workspace, Office Space, & Storage for the A/V Contractor business.

Project Status: Making final decisions about design, construction scheduled to begin with footer work in the spring, basement walls immediately after, - March if we’re lucky. It’s not too late to make changes!

Known Construction Challenges:

Attaching to existing house at correct heights.

Sloping lot - 30ft. drop over 300ft. length of lot. < somewhat improved >

Excessive ground-water needs adequate drainage. < improvements made and more plans in-place >

Driveway needs reworked. < major improvements made >

The patience of my wife of 25 years, who does not like change.

Noise Issues: Typical neighborhood noises - not complaining, just listing all the things that could wreck a recording.

Road noise - cars, trucks, Harleys, punks with car stereos I can literally hear coming a half mile+ away.

Moderate truck traffic with potential for much more if they make I-80 a toll road through PA. (which state lawmakers are trying to do)

The big trucks are a problem here. They're either coasting and Jake-Braking down one grade, or going like hell to get up the other side.

Neighbor’s idling big rig - sometimes rumbles for hours at a time, especially in cold weather.

Snow plows - an earthshaking rumble as they scrape the ice and snow off the roads in the winter.

Barking bird dog(s) in their pen - sometimes hours on end - year round.

Hunting related gunfire - sporadic and seasonal.

Lawn mowers - Neighborhood lawn mower brigade runs for hours - spring through fall.

Motorcycles (on and off-road) - loads of Harley traffic and the occasional ATV or dirtbike on the property behind us.

Helicopters - the good folks at Stat MediVac fly over regularly, between 2 local hospitals and interstate accidents.

Jets - that’s right... Jets. A couple times a month - F18s, A10s, C130s, etc. ripping through here full-throttle at tree top level. We apparently live at a navigation point for training flights and they hit a spot 1/4 mile East of here and bank hard North just outside my window. That leaves us in the loud wash, but it doesn’t happen enough to be a huge problem. And heaven help me, I love watching them go by, when I can look fast enough.

Vocation: I run my business out of our medium-size 2-story farmhouse style home.

Sound/Video Contractor - specializing in churches & schools. (95% of my business)

Professional Sound System Installation ( mixers, power amps, speakers, mics, racks, the works )

Video Projection Systems - ( screens, projectors, presentation software )

Theatrical Lighting - conventional lighting consoles & dimmers, plus new LED technologies

A/V production - Pro Tools & FinalCut Pro (5% of my business)

Special Interest / Corporate Video Production

Radio Commercial Production

Remote Recording - Live Concerts etc.

Recreation:

Still making music 2-3 times a month in a 3-pc rock / blues band

Golfing, fishing, motorcycling ( not enough free time do to any of these lately )

Research:

I have several great books including Rod's, and I've been doing my homework, reading everything on the Auralex & GreenGlue sites, at John Sayers' forum, and recently joined up here at recording.org to name a few resources.

Drawings and Pics to follow because, 'That’s all I need in life, a little place for my stuff.' - George Carlin

Comments

Welcome PITA, smooth transition from lurker to poster. I hope I

Welcome PITA, smooth transition from lurker to poster.

I hope I can do as good of a job as Max has done with pix and updates. I would love to have a jointer and a planer and a stack of lumber, but I just don't see that happening. I'll never have Max's wood-working capability and I've made my peace with that. But I will try to document as much of the process as I can. I believe the energy-efficiency of ICF is going to lead more builders that way in the future.

Seems like we've been stuck in the planning stages forever, but it looks like it may finally be gearing up for a Nov. start. My ICF/concrete contractor has been booked solid all year, and just had knee surgery this week. So he feels like as soon as he's back on two feet and ties up a couple loose ends with his big projects, he'll have time to get to work on my little project. (he hasn't used the word "piddly", but I know 200 yards of concrete is a small project to him)

We've already had a little short-lived snowfall here in PA, so that got everyone's attention - as if it may be an early winter. This is at least a four-stage pour with the concrete, so all we can do is hope it doesn't get too cold. The other contractor who I'll have doing the roofing, says he's not afraid to do roof trusses and sheeting in the snow. He says he's had to shovel snow off roofs before to do the shingles. So that's good to know, I guess. It looks like I'll be using that new sheeting for the roof that's bonded with titanium or something to make it water repellant and doesn't require tar paper - so it can wait until spring for the shingles. I would love to be able to button it up and get to some inside work during the winter months. (wiring and drywall, etc.)

Anyway, nice to know someone will be interested. I'll do my best to keep you posted.

Updates appreciated. I am heart torn between finding a old stone

Updates appreciated. I am heart torn between finding a old stone church for both residence and studio build or building a new structure. I really like the idea of a big stone church. Trying to find one thats within my budget or isn't falling down is proving challenging. Not to mention it has to be near a larger metro area to be viable as a business plan.

One thing we have going here is we are in a pretty nasty property value depression so prices are getting down to reasonable.

Anyways yes keep me updated.

Its either that or I am going to find a gaint peice of bedrock mountain to cut my way into. Awesome isolation in the side of a mountain. No mountains out here though.

But a big studio hal cut into a mountain on a nice high peak.

Wow that would be truly glorious. But who could afford the blasdting and excavation ?

LOL.

And so it begins..... About a year since the last meaningful

And so it begins.....

About a year since the last meaningful post regarding any progress. You'll notice in the pics from Page 1, it's been so long that the big pile of topsoil pushed aside during the site-prep excavation last Nov. has grown 3 ft of grass & weeds. As well as 3 ft. of grass gowing on the exposed clay (which the locals seem to enjoy)

He's standing on the very top of the overgrown pile of topsoil.

This area is all clay and you get an idea how deep the grass is and an idea how wet the clay has been to grow grass like that.

ANYWAY....

I had to switch to a different, (more responsive) ICF contractor. We could never find the right time to get started with the original ICF guy. I'm definitely not saying it was all his fault - the shaky economy and last year's early winter were factors on the construction-end as well. So we wish him well and have moved on to a guy a little closer to home who knows how to return a phone call. I've tried several other local concrete guys who had done a little ICF - but none of them seemed up to the task. I was telling my problems to a friend who is a general contractor and couple Sundays ago. And he said , "have you called this guy (Joe)?" That day, he called Joe - Joe called me and an hour later I had my plans on his table. A week later Joe had a written quote as promised, and a week after that we've got a contract and a schedule.

Which promptly leads to a yard full of diesel powered hydraulics and testosterone. The weather here is fairly mild for this time of year, so we're moving ahead with an eye on the forecast.

I've been working ridiculously long hours minding my business, while the expert excavation and concrete professionals take care of the first stages of the project and I get to come home and see something that finally resembles progress.

The equipment moved in on Monday, the earth-moving began Tuesday and continued through Wednesday and near as I can tell by the moonlight when I get home at 2am, they've got the perimeter dug down 14' 6" to what looks like the depth of the footer. (13' 6" for the rest of the area)

I took these out the kitchen window before I left his morning, while waiting for the bacon to cook. I'd love to stay and watch them do their thing, or better yet, put on my muck boots and get dirty - but that isn't going to pay any of the eeeeNORmous bills involved.

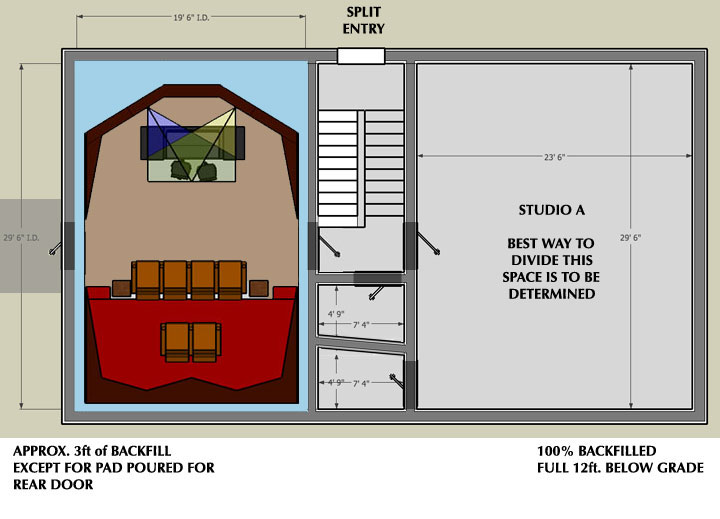

I'm entertaining all suggestions on how to best divide this spac

I'm entertaining all suggestions on how to best divide this space for the tracking room. approx 23' 6" x 29' 6" (hoping to net about 11ft of ceiling height)

one big space

drum booth - no booth

The floor above is engineered for clearspans up to 40ft, so theoretically we should be able to go without any load-bearing walls in that space, if that's the consensus. There will be tubing in the polished concrete slab for in-floor heat, so if we're going to add non-load-bearing walls for isolation later - we'll need to be sure it maps out OK with the tubing locations.

In any case there will not be any 90˚ corners, I was thinking of making good sized corner cabinets to provide much needed storage and act as a bass trap. Would that work?

Max you're off the hook, because you've got enough on your plate right now - but the rest of you, if you get a minute let me know your thoughts on what you would do with that space as a tracking room. I would appreciate any input you might have.

Thanks,

Dave

WOOT! Progress!! Congrat's bro!!! Call me a drummer, but IMHO,

WOOT! Progress!!

Congrat's bro!!!

Call me a drummer, but IMHO, I'd shy away from a drum booth and shoot for an Iso Booth if anything.

Here's my take... such as it is....

To make your room more appealing to get used, the single biggest problem that all these project studios out there have problems with, are drums.

A great sounding room for drums, is a great sounding room for piano, Hammie, gats, bass, horns (for the most part), and even vox!

You make a drum booth and you'll get good drums, but not great drums... Project studios get "ok" drums... "ok" drums for free vs good drums and a cost to them, is harder to justify than "ok" drums for free vs GREAT drums at a cost.

Just guess what I'd go for? :)

MadMax wrote: WOOT! Progress!! aaaah, the sweet smell of mud...

MadMax wrote: WOOT! Progress!!

aaaah, the sweet smell of mud..... smells like progress.

Gentlemen,

Thanks for the input.

Max get back to work, the anticipation is killing us!

avare wrote: ... I would put the iso booth in the north east corner. You have enough space to make fair sized for an iso booth.Good luck!

Andre

Any particular shape or dimensions you might suggest as optimum?

Thank you.

Make a brown roux with one stick of butter and one half cup of f

Make a brown roux with one stick of butter and one half cup of flour. Add a half cup of shallots to the hot roux and stir until transparent. Add a quart of brown stock, two bay leaves, a sprig of sage and a sprig of thyme. Simmer for 15 minutes. Add a cup each of dried cherries and roasted chestnuts. Add cognac and kirshwasser to taste. Thin with more stock if necessary. While that is simmering, salt and pepper enough 1.5 inch medallions of venison loin for four (depends on the size of the loin of course). Put in a very hot cast iron pan filmed with canola or grapeseed oil. Do not crowd. Use two pans if necessary. Turn after 1.5 minutes. Top each medallion with a bit of butter and put the hot pan into 400 degree oven. After one minute in the oven, turn baste with drippings and return to oven for one minute. Repeat. This should be medium rare (120 degrees internal temp) for a two inch wide, 1.5 inch thick medallion. Adjust time for degree of "doneness" desired and size of medallions. Let meat rest, lightly covered with foil, for at least two minutes. Deglaze pan with cognac, and incorporate pan juices with sauce, skimming fat if necessary.

Serve medallions with sauce, cherries, chestnuts.

dvdhawk wrote: Welcome PITA, smooth transition from lurker to po

dvdhawk wrote: Welcome PITA, smooth transition from lurker to poster.

I hope I can do as good of a job as Max has done with pix and updates. I would love to have a jointer and a planer and a stack of lumber, but I just don't see that happening. I'll never have Max's wood-working capability and I've made my peace with that. But I will try to document as much of the process as I can. I believe the energy-efficiency of ICF is going to lead more builders that way in the future.

Seems like we've been stuck in the planning stages forever, but it looks like it may finally be gearing up for a Nov. start. My ICF/concrete contractor has been booked solid all year, and just had knee surgery this week. So he feels like as soon as he's back on two feet and ties up a couple loose ends with his big projects, he'll have time to get to work on my little project. (he hasn't used the word "piddly", but I know 200 yards of concrete is a small project to him)

We've already had a little short-lived snowfall here in PA, so that got everyone's attention - as if it may be an early winter. This is at least a four-stage pour with the concrete, so all we can do is hope it doesn't get too cold. The other contractor who I'll have doing the roofing, says he's not afraid to do roof trusses and sheeting in the snow. He says he's had to shovel snow off roofs before to do the shingles. So that's good to know, I guess. It looks like I'll be using that new sheeting for the roof that's bonded with titanium or something to make it water repellant and doesn't require tar paper - so it can wait until spring for the shingles. I would love to be able to button it up and get to some inside work during the winter months. (wiring and drywall, etc.)

Anyway, nice to know someone will be interested. I'll do my best to keep you posted.

Out here in the mitten state. We have contractors that will pretty much shingle in a blizzard.

Are you talking about self adhering rubber ice dam with the metal coating?

GP's PlyTanium is their exterior grade Plywood. I stole a copy

GP's PlyTanium is their exterior grade Plywood.

I stole a copy of Bob's recipe... yummy... (heheheh)

As far as the shape of your tracking room... Non parallel surfaces similar to mine. (Yeah I'll brag on it, cause there ain't no flutter.)

Maybe try to use one or two corners to tuck the HVAC returns in em' and the others for storage.

Any ideas what you're going to do for finishes?

Thanks Max, LAYOUT I'll dig up the old Gemini drawings and stud

Thanks Max,

LAYOUT

I'll dig up the old Gemini drawings and study the tracking room layout.

FINISHES

I see a lot of studio pics where they have hardwood floor with an assortment of oriental rugs to put where needed. I was thinking along those lines except polished concrete floor rather than hardwood.

For the ceiling I was planning on a drop ceiling with a good quality acoustical tile with a reveal edge (where the surface of the tile comes down through the grid a quarter inch or so) for the added diffusion. Theoretically I could go almost flush with the bottom of the floor above to get nearly 12ft. of height, but I think I'll need that foot or so to be practical in allowing for ducts and recessed lighting and we'll still net about 11ft.

The walls are complete undecided. I was thinking after the shell is constructed to try to run some tests to see what the problematic frequencies are before I committed to final finish on the walls. I did think it would be nice to have some slat board on at least a couple surfaces, for hanging guitars etc. I was also hoping to do some substantially large corner cabinets for storage/bass trap purposes.

I'm willing to do whatever it takes with traps and acoustical panels. I don't have your lumber milling capability, but Pennsylvania is hardwood country and there's no shortage of companies to make whatever I want. Some of them make some interesting fluted moulding that would make nice diffusing surfaces. I have a good working relationship with [[url=http://[/URL]="http://www.edenmoul…"]eden[/]="http://www.edenmoul…"]eden[/], who is one such company that does pre-finished mouldings and other woodwork already painted or stained to a number of finishes. They may come into play for more than just trim work. We produce their marketing DVD's etc. - super nice folks and they say they'll take good care of me price wise.

But to be honest, I just don't know what the final finish will be. I'm kinda waiting to see how the shell behaves. So my first priority might be installing the crucial doors and testing the space.

In my business I have access to good/great pricing on ready made acoustical panels and diffusors. So when push comes to shove I'll have to decide whether I'd rather save a couple bucks, or save a couple days labor building my own. At the present I'm so busy with work that time is at more of a premium.

Speaking of which, gotta run. Thanks as always for the benefit of your insight / hindsight.

I've been working my tail off, so here's a quick update. Last w

I've been working my tail off, so here's a quick update.

Last week we had reasonably nice weather for digging down to footer depth and all the final excavation and site preparations.

This week we've had nasty cold weather for a few days now. Freezing rain, ice, snow, high winds, even some lightning.

Lovely weather for pouring footers, which is what they're doing today. (20 degrees and gusty)

Excavation guy, concrete guy, and HVAC guy seem to be on the same page. And the inspector has been OK with the changes I wanted to make to the approved drawings. They all seem to be communicating well and have a workable plan in-place, so we're hoping they all keep on playing nice.

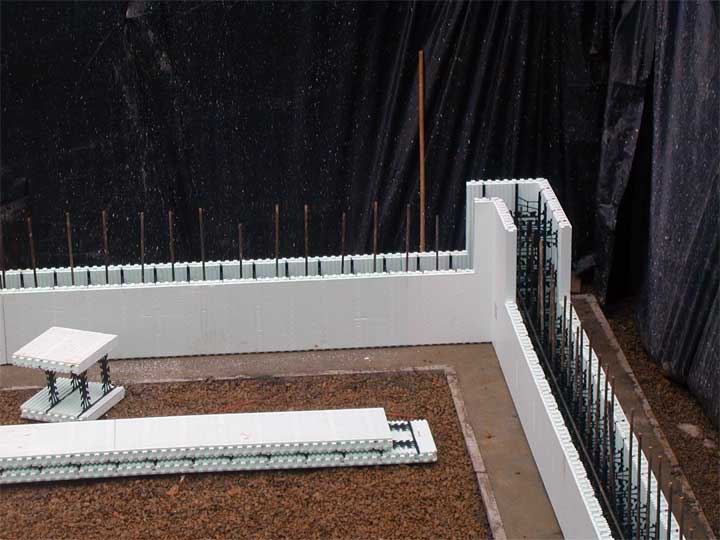

Warmer weather is on tap for next week, so they might start the first few courses of ICF, then pour basement floor next week.

Pix to follow...

Prepare for the onslaught of photos!! If you bore easily with c

Prepare for the onslaught of photos!! If you bore easily with construction you might as well bail out now...

Fun fact: Air temperature is 20 degrees, wind chill 5 degrees, and we have to wait for the other cement trucks due to demand. Hard to believe anyone else is dumb enough to be pouring concrete under these conditions.

Drain going in place outside footing

6" drains below slab that run to daylight

Form-a-drain forms in place 42 w x 12 d around perimeter - wooden forms make the footing for the interior bulkhead load-bearing walls. (also 42 w x12 d)

Form-a-drain provides radon vent pipes - might as well use them

Can I get a caveman grunt? That's an impressive machine.

Pumping concrete into the part of the footer that has to step down to accommodate the back door.

The pump operator just walks around with a remote control ...

while the concrete guy guides the flow. The other two guys standby waiting to vibrate the wet concrete

Not footprints, marks left by the vibrator prior to finishing. Covering it immediately with special blankets to retain the ground temperature.

The Putzmeister a fine bit of German engineering.

All for now.

There was more work done today, but photos aren't sized for web yet.

WOOOT! [Tim Allen Grunt]ARRR! ARRR! ARRR! [/Tim Allen Grunt]

WOOOT!

[Tim Allen Grunt]ARRR! ARRR! ARRR! [/Tim Allen Grunt]

There ya' go man!!!

This is gonna be a fun thread to watch!! I can't wait to see the next installment!!

As a sidebar note... I created an action in Photoshop to resize images, rotate CW and rotate CCW... Saved them in a new action pallet. Then I assigned each one to a function key.

Then I can just batch resize a whole folder in a few minutes. Then I go back and open all the images and rotate which ones I need to.

From the time I download my pix until I'm uploading, is probably an average of 15 minutes for ~20 images.

Keep after it bro!!!

You're officially on your path...

to insanity! :)

They're good guys. This was another cold day, so they might be

They're good guys. This was another cold day, so they might be huddled up in the corner just to keep warm.

The full 55 x 32 basement is 12ft. deep. I'm hoping to net about 11ft of ceiling height in the basement for a tracking and control room. Plus another largish room on the floor above that will be a bit more lively.

The lot slopes as you can see in the top picture. The front of the building (one of the 32ft. walls) will be to the right in those photos. So, the front-side of the basement will be completely below grade, while the back of the basement will be mostly exposed.

We've had fairly mild weather this week and in short order we go

We've had fairly mild weather this week and in short order we go from this...

to this...

Yesterday we got more conduit in place before they pour the slab and the vapor barrier is down.

Pics to follow ---

We would have placed the 1" stryofoam on top of the vapor barrier, but we were concerned it would blow away with nothing on it.

The HVAC guy is scheduled for Monday to layout and pressure test the tubing for the in-floor heat. Then (weather permitting) start pumping more concrete Tuesday or Wednesday.

camsr wrote: How do they join the ICF to the door frames? With

camsr wrote: How do they join the ICF to the door frames?

With the rough opening already established the builder installs the bucks or 2 X pressure treated framing you see in the picture(s).

The 2X material at all openings will be braced up securely as will the ICF form. Horizontal stretchers placed in the inside of the rough opening will keep the material from bowing into the hole.

They may use tape to lay over the vertical seam as it should be very thin. But the ICF form will butt into the pressure treated material so the rough opening framing material becomes the stop for the concrete. They will take extra precaution with bracing diagonally AND to prevent lift from the smooth pouring concrete.

Either pins are bored into the p.t. wood and re-bar dowels are installed or, after the pour and satisfiable curing has elapsed, the p.t. material is tap-coned into the cured concrete or hard nails, fluted nails, etc maybe used.

4 1/2 ft down, 28 1/2 ft to go (vertically). It's just like bu

4 1/2 ft down, 28 1/2 ft to go (vertically). It's just like building with Legos... big expensive Legos that will be filled with steel and concrete soon.

Davedog wrote: Ya gotta a LOT of work to do....70 more pages to fill... 8)

As much as I we all idolize Max's perseverance - if this drags on for 5+ years I'm going to be swinging from a tree somewhere out back. (maybe voluntarily, maybe by popular demand) :)

camsr wrote: Looks like the ICF wasn't able to give you the non-perpendicular walls for the iso booths. The least of worries I suppose. How do they join the ICF to the door frames?

Although you can do any curve or angle you can think of with ICF, I decided not to push for the angled walls. Once the HVAC guy showed me what he had in mind I had to face the reality of needing some space for mechanical stuff. The targeted "iso booth" closest to the exterior wall will have penetrations for the in-floor tubing etc. and I might end up using it as my equipment room. We'll have a couple other places for loud guitar amps and probably use the iso-booth more for video voice-over and radio spot VO than singing. So I'm hoping one cozy booth will be enough.

[ I'm still wide open to suggestions on specific shapes and sizes of dividing walls of tracking room - if any ]

I'll take some photos of how the rough opening door frames are tied to the forms. The snow is piling up now, I'll see if I can get some new pics tomorrow.

MadMax wrote: That's the basement level, ain't it???

I thought the studio is actually on the next floor up...

The control room and tracking room are basement level and there will be a large room directly above the control room with a cathedral ceiling for a slightly more lively room. It will be wired for tracking too. 2-way video monitoring instead of glass to the control room.

It's a winter freaking wonderland...., but we didn't get nearly

It's a winter freaking wonderland...., but we didn't get nearly as much snow as the East Coasters.

The concrete crew covered the top of forms with plastic on Thursday so they wouldn't fill up with snow - that would be bad.

camsr,

To tie the door bucks to the ICF they just span the gap with plywood and screw it across the frame and nearest ICF firring strip, then shoot any cracks with an expanding foam. Then they remove the bottom board of the door buck frame after everything is secured to the ICFs. The plywood obviously comes off after the concrete sets up.

In the upper left corner of this second pic, you can see a piece of plywood in the middle of the wall. This manufacturer suggests starting with full blocks in the corners and having the one seam up the middle of the wall. The thinking apparently is, give the drywaller (or other interior finisher) a factory edge in the corner and cut to fit in the middle. (They mark them with an X so they don't forget about them in the fray). Then you use lumber to strap across the seam. The forms have a composite firring strip embedded every 8" - which is clearly marked every 8" on the ICF. That makes it pretty easy for a drywaller to align his screws etc. when the time comes.

Most of the Control Room conduits set in the gravel under the 10 mil vapor barrier, waiting for R5 foam, in-floor tubing, 6 x 6 x #10 WWM, and concrete. Most of the goodies will be racked by the console, but I'm planning for a few ancillary racks.

Lookin' GREAT! Yeah, if you take as long on this build as I did

Lookin' GREAT!

Yeah, if you take as long on this build as I did mine... I'LL be there to HELP string you arse up in the back yard!

With my place, I was willing to take the extra time, as I knew I had a tight budget to start with, and I figured I was gonna have to fund it as I went along. In your case, starting completely from scratch, you should move along rather quickly.. another advantage of ICF!!

After a lot... and I mean... A LOT of research, head scratching, and general ponderin', I rapidly, (and now probably will end up rabidly), support and promote 30 degree angled front walls for a control room.

This deal with 60 degrees is understandable for itty bitty home/project level studios where space is such a limiting factor... but in your case, you've got plenty of space to work with.

You have a much larger sweet spot, less nodal and modal issues in the space, and nice big areas for tucking HVAC ducts, bass traps, or even sofit mounted monitors... if you so desire to go through that expense and insanity.

Everyone, I think, is pretty much in agreement that you want to sit at the apex of a 30 degree equilateral triangle. By maing your walls 30 degrees, your monitors sit exactly 90 degrees to the walls, and (if built correctly) you simply need an SBIR absorption panel behind your speakers.

Just my (rabid) $.02 worth...

MadMax wrote: With my place, I was willing to take the extra tim

MadMax wrote: With my place, I was willing to take the extra time, as I knew I had a tight budget to start with, and I figured I was gonna have to fund it as I went along.

Yeah, for the past 5 or 6 years I was dumb enough to think that bustin my hump and aggressively putting money in the bank rather than a hole in the ground would be the fiscally responsible thing to do - thinking maybe I could pull this off without having to borrow any money. As it turns out, the 3 major components of this project (concrete, steel, and drywall) have essentially doubled over the last few years, especially post-Katrina. [ like I need to tell you... ]

So with the benefit of crystal clear 20/20 hindsight, I would have been further ahead to borrow 100% of 1/2 as much money, 5 years ago. It would have been done and paid for a long time ago.

On the monitor front, I'll have to do some head-scratchin and ponderin of my own on the final speaker placement. Naturally a wider sweet-spot would be the ultimate goal. I'd like to offer some small training classes in there, so I'd like to have something presentable all the way to the back of the CR, one way or another.

Am I to assume the monitor speakers need to be closer together if they're aimed more toward the back wall? I know with my live system installs, I use cabinets with very specific horn patterns and try to avoid reflections off the side walls. This seems like it would have to be the same concept.

Hello DVD. Just stopped by to see what you are up to. I used s

Hello DVD. Just stopped by to see what you are up to. I used similar ICF for my outer "shell" and stuccoed the outside. I just love this way of building now though I had my doubts at first!! If you get a chance, and can wait for the pix to upload, you can see some of my structure (24' walls in 3 pump truck pours.) at vibrationsrecording.com. It's a blog my wife set up for me as I'm fairly computer challenged but getting better. I did the loan thing to get a shell up that I can pick away at over the next millenium probably. Keeps me busy but you know all about keepin' busy now more than ever eh?! Lookin' good! Good luck and thanks for your advice and input on the iso transformer. It's up and running! ciao!

First and foremost.... MERRY CHRISTMAS! dvdhawk wrote: [quote=M

First and foremost.... MERRY CHRISTMAS!

dvdhawk wrote: [quote=MadMax]With my place, I was willing to take the extra time, as I knew I had a tight budget to start with, and I figured I was gonna have to fund it as I went along.

Yeah, for the past 5 or 6 years I was dumb enough to think that bustin my hump and aggressively putting money in the bank rather than a hole in the ground would be the fiscally responsible thing to do - thinking maybe I could pull this off without having to borrow any money. As it turns out, the 3 major components of this project (concrete, steel, and drywall) have essentially doubled over the last few years, especially post-Katrina. [ like I need to tell you... ]

So with the benefit of crystal clear 20/20 hindsight, I would have been further ahead to borrow 100% of 1/2 as much money, 5 years ago. It would have been done and paid for a long time ago.

Prezackly!

When the whole economy turned down, I thought to myself that I was being a complete idiot for not keeping funds invested and trying to ride out the depression.

If I had stopped building and tried to manage the funds for minimal loss, I'd not have the studio, OR the money!

As it is, I may not have the money, but the studio has at least increased the property value. And from that aspect, the money's I've invested are still somewhat intact.

Congrats on getting your floors poured!

Your walls are at 6' now... so when will they start to pour the walls?

MadMax wrote: First and foremost.... MERRY CHRISTMAS! ... Congr

MadMax wrote: First and foremost.... MERRY CHRISTMAS!

... Congrats on getting your floors poured!

Your walls are at 6' now... so when will they start to pour the walls?

And a MERRY CHRISTMAS to you my friend!!

Next time the concrete crew comes back they'll be putting in their bracing / scaffolding so they can work up to 12ft. The bracing jacks makes a walkway all the way around the perimeter so they can work the concrete pump the whole way around to keep the mud filling in evenly.

We've got one more rough opening to triple-check the measurements of, for the split-entry (which should be a little over 6ft. above the slab). I want to bring in the contractor who will be putting in the stairs, to make sure my numbers aren't overlooking something. I have a detailed 3D model of the stairs, but I need somebody who swings a hammer for a living to make sure the virtual measurements will work in the real world.

Other than that, the remainder of the basement should go really fast. Once they get above the door-bucks, that are down at slab level, there will be very little form cutting. That split-entry door will be the only obstruction on the last 4 courses of basement forms. The horizontal rebar just locks into the webbing in the form and the vertical rebar is zip-tied every so often.

These corner forms are nice and rigid and the straight forms are 18 x 96, so you can get a lot of wall done in a hour. We're really happy with the square & plumb factor of the forms before they're even braced.

So far, so good....

It doesn't look like much, but this is from last week when they

It doesn't look like much, but this is from last week when they finished the basement slab (and covered it with those thick insulated tarps) and the next day they came back to put in the last course of forms they could do from ground-level.

As expected, they really kicked it into high gear on the two days they came back this week. They got their bracing / "staging" attached to the walls, which will eventually be used to square everything up - and as you can see it's providing a walkway to work from too.

The highest course shown is up to 12ft. .... 12ft. down (up) 21 ft. to go!

*Today's Fun Fact - before my concrete contractor moved here 15 yrs. ago, he lived in CT. and worked on the then new studio building for ESPN in Bristol. He said the slab for that building is 30-inches thick.

We've got the last of the sleeves inserted in the walls and the

We've got the last of the sleeves inserted in the walls and the last of the vertical rebar in the basement walls. All the doors are roughed in and there's wood bracing up all the seams.

Tomorrow morning, another visit from our awesome friend Mr. Putzmeister the concrete pump....

We're expecting more snow, but not too cold.

Here's hoping we didn't overlook anything that might have required a sleeve....

Snowstorm on the way, but it held off until later in the day and

Snowstorm on the way, but it held off until later in the day and the temperature was OK for pouring.

This is another one of those posts, that if you look at the pictures, you could think there hasn't been much done from one day to the next.

But the reality is, what you don't see in the 'before' and 'after' is the 81 yards of concrete pumped into the wall forms in one afternoon.

Doors frames braced and jacks in place.

Seams all braced and pouring begins.

4 Hours and 8 truckloads of concrete later - topping the forms off.

Some rough trowel work and wet-setting the rebar that will dowel the next floor to the basement walls.

*edit: the reason the right edge of this form is such a mess is because it's a brick ledge that needed concrete troweled into the pockets,

by far the messiest surface - but a good illustration of the rebar.

Thanks Max, I hope I can do half as well as you did documenting

Thanks Max, I hope I can do half as well as you did documenting it.