Hey guys, I'm doing some wiring specs (exciting right ? Lol) and I'm completely unsure of what to go with.

It's speaker wire for a cinema setup. The surrounds, and the Screen Channel speakers accept up to 10awg wire with barrier strip screw terminals. The reference speakers and subs are on speakin NL-8 connectors which accept up to 12awg wire.

625w (or 400w)per surround single amp, 625w/1150w or the refernce top tri amp, 1150w for the subs (dual 12") single amp. Same for the screen channel speakers 625w bi amp, 1150w for the subs (dual 18") single amp. Lol the 21" sub will be for fun someday. 2500w...

The manual simply states 'use the lowest gauge wire, and shortest cable run.'

The place is roughly 16x22 (tiny by film standard but it's only temporary-ish) so I would imagine the average cable run between 20-50ft.

It's going in my yet to be built or even drawn, home studio room. I'm gonna work out the electric and physical runs so they should be clear of any interference.

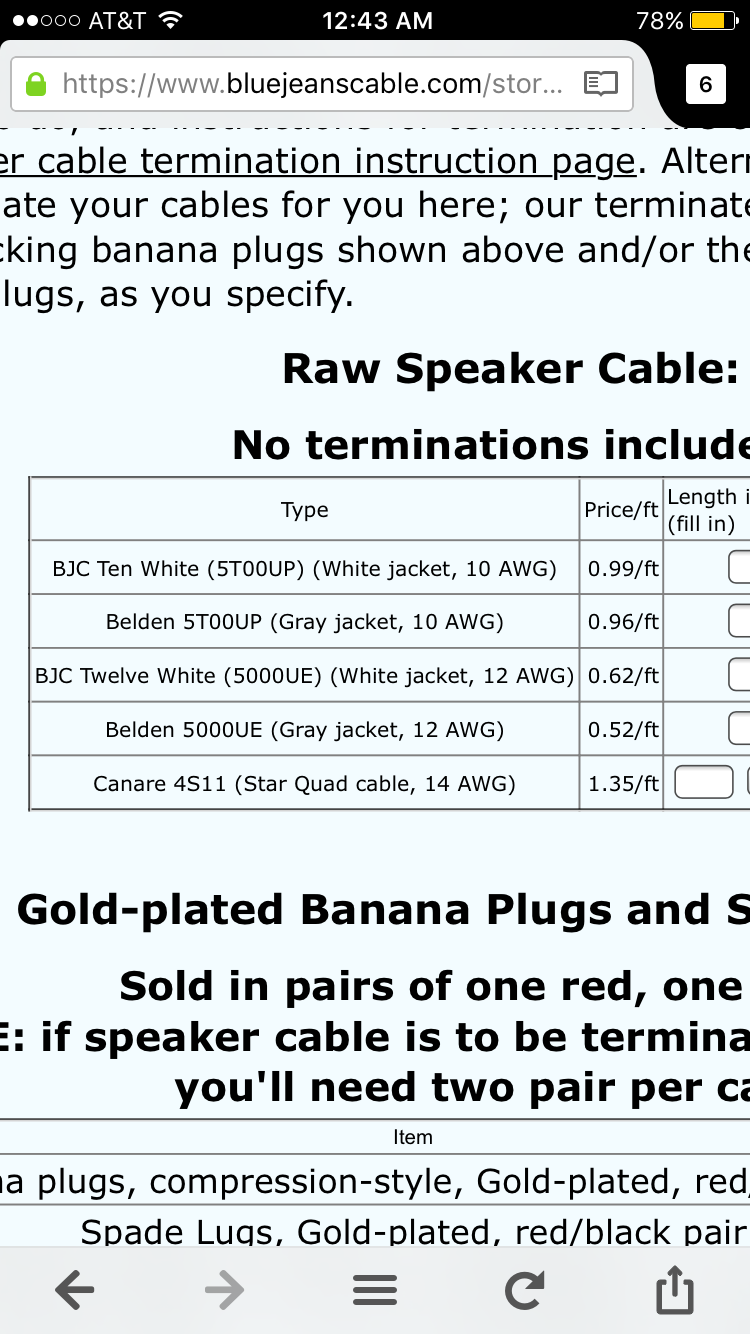

So it looks like there's 5 options for cable:

Belden 5T00up- 10awg 2 conductor

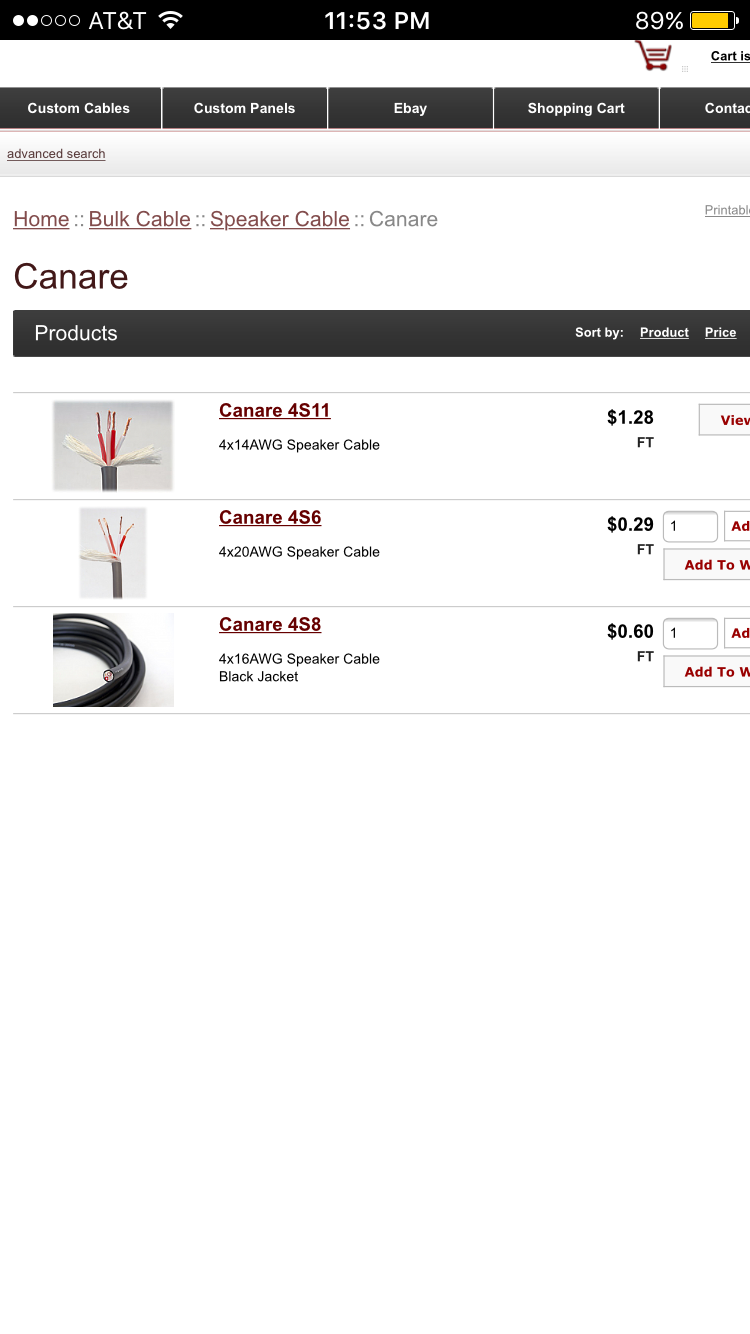

Canare 4S11- 14awg 4 conductor

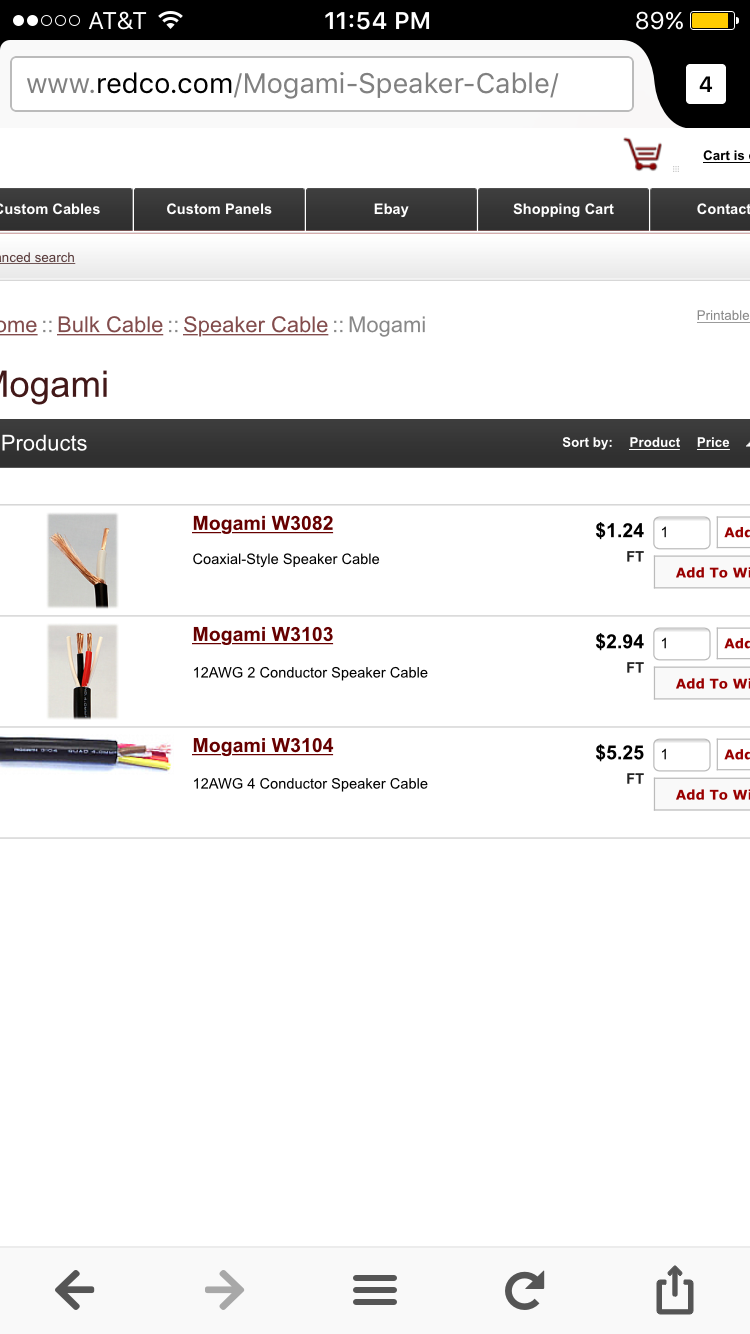

Mogami W3104- 12awg 4 conductor

Mogami W3103- 12awg 2 conductor

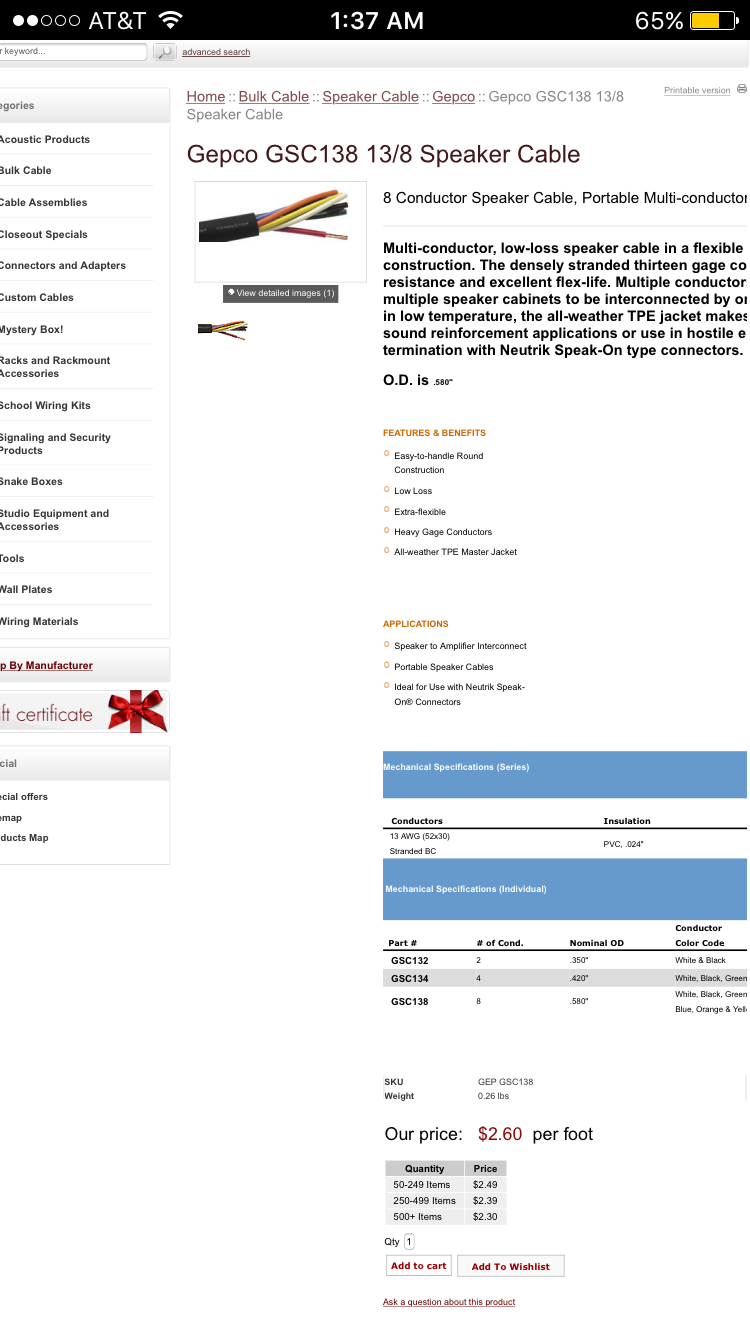

Gepco GSC138- 13awg 8 conductor.

I'll include screenshots of the w some prices but the only one that's a bit painfully priced is the Mogami w3104, at $5.25 per foot.

But that said this thing has got to be as technically correct as possible becuase there's nothing cheap about the cinema system. Besides that the runs are short enough to not be disgustingly expensive with any option. The system design is all about max headroom and efficiency with minimal components.

I feel proper setup, spec, and calibration, will help maximize the results of some of this stuff which is low-mid pro standard class.

So anyway it seems 8 conductor wire for the NL8 speakons makes sense. Gepco is usually a decent budget wire. I'm open to options.

As far as 2-4 conductor I'm wondering if the 4 conductor wire is overkill becuase the system is gonna be pretty interagency free. Should I use that for Bi amp applications? Is it overkill for a per channel basis?

Also is the 2 conductor 10awg better overall than the 12-14awg 4 core.

Honestly I'm kinda lost on this whole thing. I'm not used to things that are both high power and high quality.

Is there one technical ideal to shoot for?

I'm gonna work on my mobile system wiring while I'm waiting for response on this. But I'm getting the gear budget ready for the accountant and there's a significant (50% approx)jump between the 12awg 2 and 4 core. I don't mind whatever it ends up costing as long as there's no waste, and no compromise. 'Just right' is what I'm shooting for.

Thanks.

Comments

I'd put in 12AWG for all of it, maybe 10AWG for the sub(s) if yo

I'd put in 12AWG for all of it, maybe 10AWG for the sub(s) if you're just trying to show off.

I have installed MILES of this stuff: JSC 12AWG 4/c and JSC 12AWG 2/c with very satisfactory results at a much better price.

PROS:

Excellent value, High strand-count (65), In-Wall CL3 rated, 99.9 pure copper, Made in the USA. Durable outer jacket, Incrementally marked.

CONS:

UPS can break the plastic spool in transit, it can be on the stiff side, the outer jacket is difficult to strip/cut.

I'll leave it up to you whether the white color of the jacket is a pro or con. It's usually a 'plus' in church installations. If it's in-wall, who cares?

I don't mind the difficulty cutting the outer-jacket, its toughness is the exact thing that makes it good for pulling through stud-bays etc. and also what makes it a little stiffer than some other cables. A more flexible cable with a softer jacket, is more prone to getting nicked up pulling around bends and scraping over nails and sharp surfaces. The JSC and Belden, made specifically for in-wall use, would both be harder to ruin in those cases.

Like Boulder, I have mostly 12AWG in my live rig. I keep almost all of my speaker cables under 30ft. If I'm running one of the smaller configurations, there's just one amp-rack behind the near stack (with 5ft. and 10ft. cables) and the farthest stack is no more than 30ft. of 12/4 away. If I'm pressing the bigger configuration into service, I add another rack full of identical amps (one behind each stack) and run XLR from the Main amp-rack to the far amp-rack. That keeps all the speaker cables under 10ft. If I have to go full-scale, I do have some 10/4 SOOW cables. I've used a few short-ish 13/4 cables and been satisfied with the results. I can tell you first hand, the 10-gauge will have to lose some strands if it has to fit in a SpeakOn cable end.

Back when I was working slightly bigger stages and running 4-way, the speaker harness consisted of 10/2 for the subs, and 2x 12/2 for the low-mids, 12/2 for high-mids, and 12/2 for highs. So it was a bundle of cables about the size of your wrist. On the rack-end, NL8s for the mids and highs, and an assortment of smaller (idiot-proof) Hubbells connecting to the mid and high cabinets. Plus, Hubbell connectors the size of soup cans at both ends of the 10/2 sub cables, There was one big amp rack, and the far-side cable run was 65ft. the near-side as 15ft. The loss wasn't terrible on the long run, most people would never notice. But if you listened carefully from FOH, you could definitely tell which side had the extra 50ft. of cable.

The biggest challenge using 4-conductor in a NL4 SpeakOn to NL4 SpeakOn cable, is the unavoidable twist on one end. The position of the conductors is the same through the length of the cable and with a normal male <-> female cable, the pinout is mirror image between the two connectors - easy. With an NL4 to NL4 cable you're making a cable that's female to female. The pinout that works perfectly at one end, will be bassackwards when you get to the other end. For me, compensating for this on a 4-conductor SpeakOn cable usually means cutting back a little extra jacket on one end to allow for the twist, assembling the connector, then adding a couple layers of heat-shrink tubing to make up for the loss of the jacket. For my current live rig, some of my cables avoid the 4-conductor "twist" completely by terminating the stack-side with a breakout box that consists of a single gang outdoor type water-proof box, a beefy water-tight cable connector, and a stainless steel wall plate with 2 SpeakOn NL4 panel-mount males (one for sub / one for tops) soldered onto the 12/4 - then I use 10ft. and 5ft. SpeakOn cables to drop to the breakout box. (quick, easy, durable, scaleable) There is always insertion-loss when you add another connector in the path, but it's very minimal in this particular real-world application. [I can post a picture if that doesn't make sense]

Thanks for the replies fellas. Your expertise is always apprecia

Thanks for the replies fellas. Your expertise is always appreciated. I have a few more questions I'll put after the quote replies.

bouldersound, post: 440380, member: 38959 wrote: How long do you expect to run the system wide open at a time? Probably not more than ten seconds and probably not more than once or twice in your life.

Precisely. If I live past the first time lol.

bouldersound, post: 440380, member: 38959 wrote: So all that speaker and amp capacity is mostly there for headroom to accommodate occasional high peaks

Yes. My thought being it lend to a killer dynamic range, and super fast transient response, which should help keep phase anomalies minimized.

bouldersound, post: 440380, member: 38959 wrote: Point being that any of those listed products will perform well enough so maybe focus more on things like meeting code (for in-wall), cost and ease of assembly.

Cool, ya know i hadn't accounted for in wall yet. Thanks, good call. Cost and assembly ease are 'cry once' factors so less crucial to me.

dvdhawk, post: 440383, member: 36047 wrote: I have installed MILES of this stuff: JSC 12AWG 4/c and JSC 12AWG 2/c with very satisfactory results at a much better price.

Sweet this stuff looks cool. Significantly cheaper than then the others, more importantly it's in wall which I wouldn't had to start from scratch on. Thanks you saved me a ton of time, I'm gonna leave that as a place holder for the surrounds.

dvdhawk, post: 440383, member: 36047 wrote: I'll leave it up to you whether the white color of the jacket is a pro or con. It's usually a 'plus' in church installations. If it's in-wall, who cares

Yup in the wall, who cares.

dvdhawk, post: 440383, member: 36047 wrote: Back when I was working slightly bigger stages and running 4-way, the speaker harness consisted of 10/2 for the subs, and 2x 12/2 for the low-mids, 12/2 for high-mids, and 12/2 for highs. So it was a bundle of cables about the size of your wrist. On the rack-end, NL8s for the mids and highs,

Does this mean for the low mids, you had 2 of the 4 conductors in the positive terminal, and the other two in the negative? Like 'doubled up' I'm completely a newbie with 4 core wire, barring the neglex/star quad we put in Normandy, which i ran, but didn't solder, I oversaw the soldering tho.

dvdhawk, post: 440383, member: 36047 wrote: The loss wasn't terrible on the long run, most people would never notice. But if you listened carefully from FOH, you could definitely tell which side had the extra 50ft. of cable.

Funny you mention this. I've been contemplating whether or not it makes sense to have identical length cables for the front speakers. Even the surrounds. We're talking about 5-10 feet of 'extra' slack or 'waste' if I matched the lengths exactly. Financially it wouldn't be a concern. I'm looking for technical ideal. Even though In reality the symmetry wouldn't be identical since one wall borders the house foundation and one wall wouldn't. So it's gonna take some calibration anyway.

That said one less thing to compensate for is good w me.

Not sure what the right thing to do is.

dvdhawk, post: 440383, member: 36047 wrote: The biggest challenge using 4-conductor in a NL4 SpeakOn to NL4 SpeakOn cable, is the unavoidable twist on one end. The position of the conductors is the same through the length of the cable and with a normal male <-> female cable, the pinout is mirror image between the two connectors - easy. With an NL4 to NL4 cable you're making a cable that's female to female. The pinout that works perfectly at one end, will be bassackwards when you get to the other end. For me, compensating for this on a 4-conductor SpeakOn cable usually means cutting back a little extra jacket on one end to allow for the twist, assembling the connector, then adding a couple layers of heat-shrink tubing to make up for the loss of the jacket. For my current live rig, some of my cables avoid the 4-conductor "twist" completely by terminating the stack-side with a breakout box that consists of a single gang outdoor type water-proof box, a beefy water-tight cable connector, and a stainless steel wall plate with 2 SpeakOn NL4 panel-mount males (one for sub / one for tops) soldered onto the 12/4 - then I use 10ft. and 5ft. SpeakOn cables to drop to the breakout box. (quick, easy, durable, scaleable) There is always insertion-loss when you add another connector in the path, but it's very minimal in this particular real-world application. [I can post a picture if that doesn't make sense]

If you have a pic handy it'd be welcome. No need to go out of your way.

I'm planning on running point to point as much as possible so I'll avoid any extra connections whenever i can tho, in reality like you said it's a minimal effect.

The main 3 refernce speakers and there 3 subs take the NL 8. The rest are screw terminals. The amps are 'euroblock' connectors which I'm unfamiliar w. The Google pics look like basic wore harness type things like on a car radio.

Questions / Confusions:

Does 4 c wire mean I treat them as two separate wire pairs aka 1 wire-2 speakers, or is it 4 conductors for a single speaker.??

What's the 'rules' on this.

How do I fit 8 connections into one connector lol. I had in mind stripping the sheathing and heat shrinking like you described.

My thinking is 1 physical wire (2-4c) per amp channel / speaker input. This helps me if I have to repair something. And since I'm terrible at soldering right now, I'd rather not screw up a 8ch cable lol. I'm bound to make some mistakes.

As I see it, I'll use the 10awg just for the standalone subs, and 12awg for everything else. There isn't a strong reason not to use 10 for the subs. And since the NL connectors won't accept 10 anyway, no sense forcing it. 12 for the surrounds should be more than adequate it not overkill, but is pretty affordable. I don't see a reason to use 10 for a 4-650w speaker 15 ft away. Although the the thought of it is 'cool' to me lol. 12 should be fine.

10 on the large screen channel 'stereo' mains as I'm calling them is still a maybe. But technically those are slightly underpowered anyway, based on qsc reccomendations. This is becuase the way the surround setup works I end up w to 'extra' amp channels on the low amp and the mid/high amp.

So i thought it'd be perfect to use them for a set of stereo 'bigs' since I've been dying for a pair since I used uerie 813cs.

This leaves no wasted amp channels. The amps are 1-2k each and there's 5 total soo it's sinful to leave extra.

Eventually I'll add a third screen channel speaker, and two screen channel subs and the 21" sub (for fun). But I'll need to buy amps along w them. I don't see that happening until 4 or more years from now, and likely only when I'm in 'my home' not my parents basement as this current setup is.

Thanks again. Your input is welcomed and appreciated fellas.

Lol I've already 'saved' $120 by walking to get food and living

Lol I've already 'saved' $120 by walking to get food and living supplies over the last month instead of taking the truck. Lol. If I do that for the next 20 years this system will be 'free' lmao. I think the wiring won't change much between amp and speaker makers of this type. But I will start another thread based on the actual speakers and amps, again becuase the cinema/film arena is new to me. Lol sorry I just thought of that as I stepped out into the rain.

OK, Random notes. Back then, we were running 5 amps in a 4-way

OK, Random notes.

Back then, we were running 5 amps in a 4-way system. We had 2 big sub cabinets per side, and jumped the 2 cabinets together for a 4-ohm load, and ran the 10/2 back to one big amp. [4 subs, 1 big (for the time) 2-ch amp]

We had 2 big low-mid cabinets per side that each had very different characteristics. One pair was extremely punchy, in-your-face, low-mids, the other pair was super smooth low-mid. So rather than jump them together, we ran a separate 12/2 from each cabinet. Each pair had their own 2-ch amp, so we could tailor the amp volumes to get the best results for any given venue.

We had 2 horn cabinets per side, which were OK jumped together. And we had a single cabinet containing 3 super-high compression tweeters per side, so they were jumped together inside the box.

Normally with a 4-Conductor cable it's:

Conductor #1 = Speaker #1 +

Conductor #2 = Speaker #1 -

Conductor #3 = Speaker #2 +

Conductor #4 = Speaker #2 -

SpeakOn Cable ends only require cutters, wire strippers, and a good screwdriver to assemble. You could tin the wire, but you don't need to.

The panel-mounts are available in 3 varieties:

1) Normal MP which has 3/16" solder tabs, that can also accept 3/16" crimp-on spade connectors

2) UC-Version, designed for higher power amps - which uses a ¼" solder tab, that can also take ¼" crimp-on spade connectors (also better for 12AWG wire)

3) ST-Version, which uses screw terminals

And whether you solder or crimp, heat-shrink can always be useful.

I may be the only one, but I hate Phoenix plug / Euro-block connectors.

Thanks fellas. im gonna plan on one 2/c cable per amp channel.

Thanks fellas. im gonna plan on one 2/c cable per amp channel. Just in case. It's. Not quite as neat and tidy as 4/c, so that may change, but there is some element of extra sheiding. Something about 1:1 I like.

I'm also gonna plan on symmetrical cable lengths. Again just cuz I like the sound of it. I guess technically the capacitance would be different either way because one would be coiled, but that's getting a little too picky. The racks gonna not be centered so I'll live with it. Unless it's at the rear of the 'studio' in which case I could have things identical/symmetrical. Either way, it'll be good enough.

This is actually turning out to be pretty solder free!!!!!

As far as euroblock terminals, I've never used them aside for car radio types, so I guess I can learn to hate them. Lol. Personally I thought it was an odd inclusion.

Also hawk you brought up a good point about adding speakers to change the load. I was on the fence between the 400w or 650w amps for the surrounds becuase the diff is $200. I'm gonna go w the bigger one, in case I add more surrounds I think I can do so without adding an amp. I'll double check. Either way that made me decide on the bigger amp. Sweet.

So here's the list fwiw

Mogami-12/2 cinema refernce main (650w 8ohm) Tri-amped

Mogami- 12/2 cinema subs (1150w 8ohms)

Jsc- 12/2 surrounds (650w per channel 8ohm)

Belden- 10/2 screen subs (1250w 4ohm)

Belden- 10/2 screen channel (650w 4ohm) Bi-amped

Overall this is pretty good. It lands $0.50-3.00 per foot. The 'name brand' wire is in the reference grade speakers. I know it doesn't matter much but it'll look good on the website and YouTube Ect.

I'm open to suggestion on a non name 12/2 wire you guys have had good luck w. For non-in wall installation.

Thanks again fellas, this one got solved pretty quickly and easily.

It's also helped w the design aspect too. Since the most expensive wire and most number of wires are in the front, I'm going to try and plan in the amp rack in the front of the room. My main concern was power wire cost but it appears copper is copper. So I'll likely locate the front wall speakers on the breaker wall too. Unless a significant acoustic reason arises.

Building the room around the system is a new way for me usually it's the opposite. I like it.

On second thought since I wasn't thinking about the NL8 connecto

On second thought since I wasn't thinking about the NL8 connectors. It may be simpler to use 4c for the mid/high refernce speakers. It'll keep things neat and save a little money. Since they're coming from the exact same amp, it doesn't make any sense to use two seperate cables.

From what I've read from people I trust it's not good to tin the

From what I've read from people I trust it's not good to tin the speaker wire with the Neutrik connectors. The solder flows slowly and allows the tinned end to deform, decreasing the pressure of the clamping screw. And I think there's supposed to be a copper collar or something. It's been a while and I'm talking about NL4 connectors so I could be wrong about this, but check it out before tinning ends.

Okay, definitely something I want to confirm. I've used that typ

Okay, definitely something I want to confirm. I've used that type of connector twice, once for a club install, and once for my bands PA. I didn't tin the wires for either one and had no problems. But since I've got plenty of time, there's no excuse for not making a point to get educated on it.

Kyle those are nothing like car stereo multi pin blocks in reali

Kyle those are nothing like car stereo multi pin blocks in reality. Theoretically, wire strippers and a screwdriver are all you need, but they use the cheapest metal for the set screws. And if you ever get one tight enough, a lot of times they won't come out later if you need to change something. And on the inputs, you end up having to insulate the shields on the balanced input blocks so they don't short across any neighboring wires. Give me an XLR connector for the inputs any day, and full size 5-way binding posts or SpeakOn outputs. For me, an old-fashioned terminal barrier strip is way more reliable than the newer plastic euro-phoenix version.

I've only ever tinned the ends for a SpeakOn female cable end a couple times, and it because there was a problem with the set screw and I soldered them in solid. Generally, I would avoid it because I think being less flexible would cause it to break sooner. It's not a bad idea to go through and tighten the SpeakOns occasionally.

The original SpeakOns did have a copper collet and used a small allen-wrench to tighten the set-screw. Every generation since then has gone phillips head screwdriver and done away with the collet. Now there's a small lollipop shaped metal tang with a hole in the round end that goes around the set screw, and the tang sticks down into the hole alongside the wire to give the set screw something more solid than tiny strands of copper to mash against.

Nobody can accuse the folks at Neutrik of resting on their laurels.

Man sounds like those euro block connectors suck. Thanks for the

Man sounds like those euro block connectors suck. Thanks for the fair warning! I wish they'd just put the screw terminals in. $2k for and amp and crap connections. Go figure.

I like when companies work to improve their product and actually improve it, not just make it cheaper lol. Neutrik is German I belive and I'm a big fan of German stuff. I'll be using a combo of switchcraft and nuetrik connections for everything.

Any thoughts on 12awg /2/4 wire? As I'm thinking through the room orientation I may have to put the speakers on the opposite wall of the rack... This makes the mogami stuff uncles sedately expensive. Short runs were one thing. But it's probably gonna be more like 30-40ft.

Thoughts on jsc or belden for non in wall?

Also I'm not sure what technically counts as in wall. The drywall structural wall will have an 'acoustic wall' just a basic 2x frame housing the treatments. Instead of wall panels. I was planning to do my wire runs hi/low voltage between the drywall and acoustic walls as much as possible. Both to avoid penetrations in the ISO layer, and be able to easily add more, and remove the wire when I move.

Does that count as 'in wall'??? My thinking is that in wall codes are for between the ISO walls. Not sure.

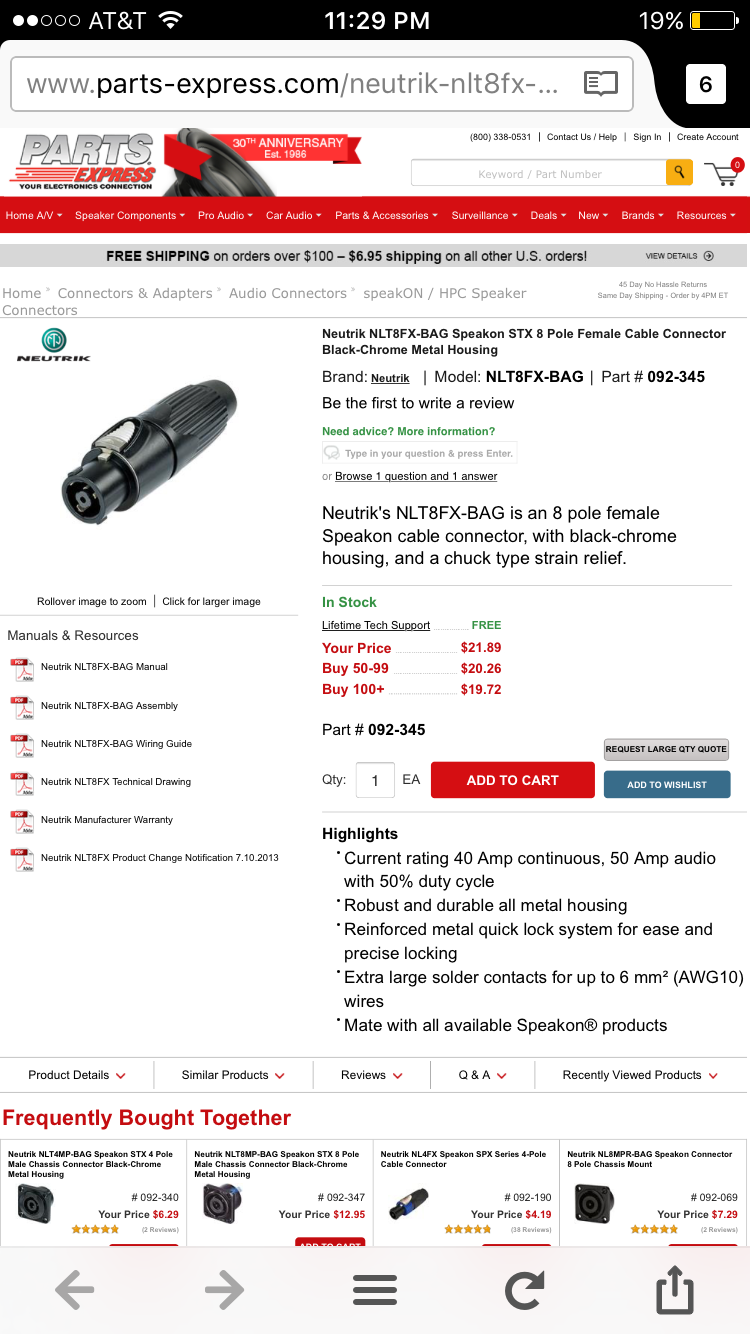

@dvdhawk Hey man have you used these ? http://www.neutrik.com/e

Hey man have you used these ? http://www.neutrik.com/en/speakon/stx-series/nlt8fx-bag

Nuetrik NLT8FX. They (nuetrik / parts express) say they fit up to 10 AWG wire. The others are rated for 12awg as you indicated.

These are all steel which I like, and $22 each, which I don't.... But I only need 6 so watever.

I'm more concerned about them fitting the wire. I was gonna order a plug and like 10' of the belden 10awg to try and fit all 8 wires in as a test. This opens the possibility of using all 10awg wire for the reference speakers. Using the in wall wire keeps it affordable an makes sense since the runs are in wall. Plus I could do individual wires for each amp channel.

The mogami is out, I just can't think of a design that has the rack on the screen wall, or near it. So it's gonna be at the rear, at least as of now. So my runs are 40' each. Between the belden and the jsc I should be covered.

I'm curious about your experience, if I can save $40 by not having to buy one plug and some wire it'd be cool. Otherwise I'll have to bite the bullet.

Sorry Kyle, I can't really comment on those specifically, becaus

Sorry Kyle, I can't really comment on those specifically, because I haven't used them. The standard SpeakOn connectors are incredibly durable, so I couldn't justify paying double for steel. I can't recall ever having a broken SpeakOn cable, but as I've said - I will go through them every few years and make sure the lugs are tight.

I don't think you're going to like the fact that those are solder connections, on the NLT8, which is probably why you can go up to 10 gauge. I'd want put a little heat-shrink on them too, which would also be a challenge. They recommend you strip back an inch of the outer jacket, then about 5/16 of the insulation on each conductor. That doesn't leave a lot of room for heatshrink, and during the soldering you'd have to be careful not to get the wire so hot that it started to shrink before it was in place.

Which reminds me…… I haven't specifically used the NLT8, but this may be of interest. A couple years ago Neutrik had just introduced a cable mount male (NLT4MX) that I thought I'd use to make a SpeakOn Male-Female extension cable to throw in the trailer in case of emergency. I'm certainly no soldering rookie, but I remember the cable mount male being a total PITA. It was impossible to get the contacts (which look very similar to the contacts in the NLT8) to "take solder". There was something about the combination of flux, solder, and/or iron temperature it did not like. I could tin the solder cup, and solder in the perfectly tinned wire, and after it cooled down, give it a little tug and pull it right apart. I scuffed up the solder cups, I tried both liquid flux and flux paste, I tried 4 different irons of different temperatures, and even a big soldering gun. Any combination of those would have worked fine on the countless panel mount males I'd soldered, but nothing that I tried worked on that cable mount male. I don't know if there's some secret combination, or if I got one that was somehow defective. As a VERY experienced solderer I did not expect it to be the slightest problem, (other than the heat-shrink scenario described above, which triggered this flashback) but it ended in frustration and expletives. So after this 5 minute project turned into well over an hour, I put a normal (set-screw) female on the cable, and as a workaround for the in-case-of-emergency kit, I bought a couple Neutrik Male to Male couplers - which is a better solution anyway, logistically.

You can decide if that's relevant. But before you drop $22 a piece on 6 of them, you might want to try 1 first.

I recently bought a pair of speakers from Clair Brothers, and they tend to favor the Amphenol EP series multi-pins in cabinets of that vintage (probably because of the metal shell). But you'll have the same wire gauge limitations. 12Awg on the EP-4 and EP-6, and I think it's 14 or even 16AWG on the EP-8. I took out their Amphenols and put in the round-flange NL4MPR version of the SpeakOn panel mount male.

Hey thanks so much! I honestly didn't even realize they were so

Hey thanks so much! I honestly didn't even realize they were solder connectors. I'm not dead set on using 10 AWG, but the price is right and it wouldn't hurt. But I'd it's gonna be absurdly annoying, or result in wasted materials due to my failed attempts it quickly becomes not worth it.

I'm gonna order a test connector and 10-15ft of wire and the heat shrink and see.

I've got a while to make the final choice but would like to be as accurate as possible w the accountant in a few weeks.

I appreciate you sharing your experience.

A certain, rather eccentric, ex-RO moderator said when she worke

A certain, rather eccentric, ex-RO moderator said when she worked at NBC that they had thousands of extra feet of cables (actively passing signal) in the bowels of the building, to insure that the cables were the same length to keep everything in sync. Discussed in these 2 links: Link #1 Link #2.

In a room the size you're talking about, it doesn't seem like a bad idea to keep your speaker cables exactly the same length, but with speaker cables shorter is always better. It couldn't add much to the overall cost and could only enhance laboratory measurements, as long as the loss/foot wasn't robbing you of something else more important. Whether or not any of this would be perceivable by human ears is anybody's guess, but the power of suggestion is powerful - so make sure you tell everyone about it so they'll convince themselves they can hear the difference. Install a switch, connected to nothing, and ask if they can hear the difference between A/B.

I think the simplest way to maintain symmetry is to just have th

I think the simplest way to maintain symmetry is to just have the amps located in the center of the room in the rear. This keeps cable runs short as practically possible with no wasted 'makeup' cable.

Instead of a 5-6' tall rack I can make it counter top height. This way it's not obtrusive and I can use the counter top to put a computer screen and keyboard and c set of speakers (Yamaha hs-5). Plus this leaves room for acoustic treatment and maybe some wall hangers for guitars.

As far as imperceivable technical compromises go, they do eventually add up if there's enough of them. So it's always good to minimize them of course. In this case they'll likely be many other things that will make a difference that is noticeable. The less technical anomalies I have to design into it the better. I think it's easy to get caught up in both perfectionism and 'it doesn't matter' schools of thought.

I once told a guy recording my cousins Mesa stack w a 58 and a berringer euro mixer "the upper mid range is harsh" to which he responded "let's not get too technical". Maybe he knew something I didn't about his aiwa stereo speaker 'monitors' I didn't. Or maybe it was the $75/hr he was charging my unsuspecting uncle....

This was all at the point where I was working w a sound blaster USB card and portastudio. As well as home stereo speakers.

I ended up making some equipment groupings/packages up to show my uncle he was getting ripped off. My uncle bought the digidesign system and had me build a little studio. Which is where I discovered rods book and RO.

Lol maybe I should thank that guy for being a con artist or apathetic.

Years later he came to the club I worked at doing live sound w a Tascam m series home studio mixer from the 70-80's. Lol. In actuality those boards sound better than any berringer but...

To me the technical choices are made by the designers so it's easy enough to just do what they say. But in the end there's always some sort of compromise.

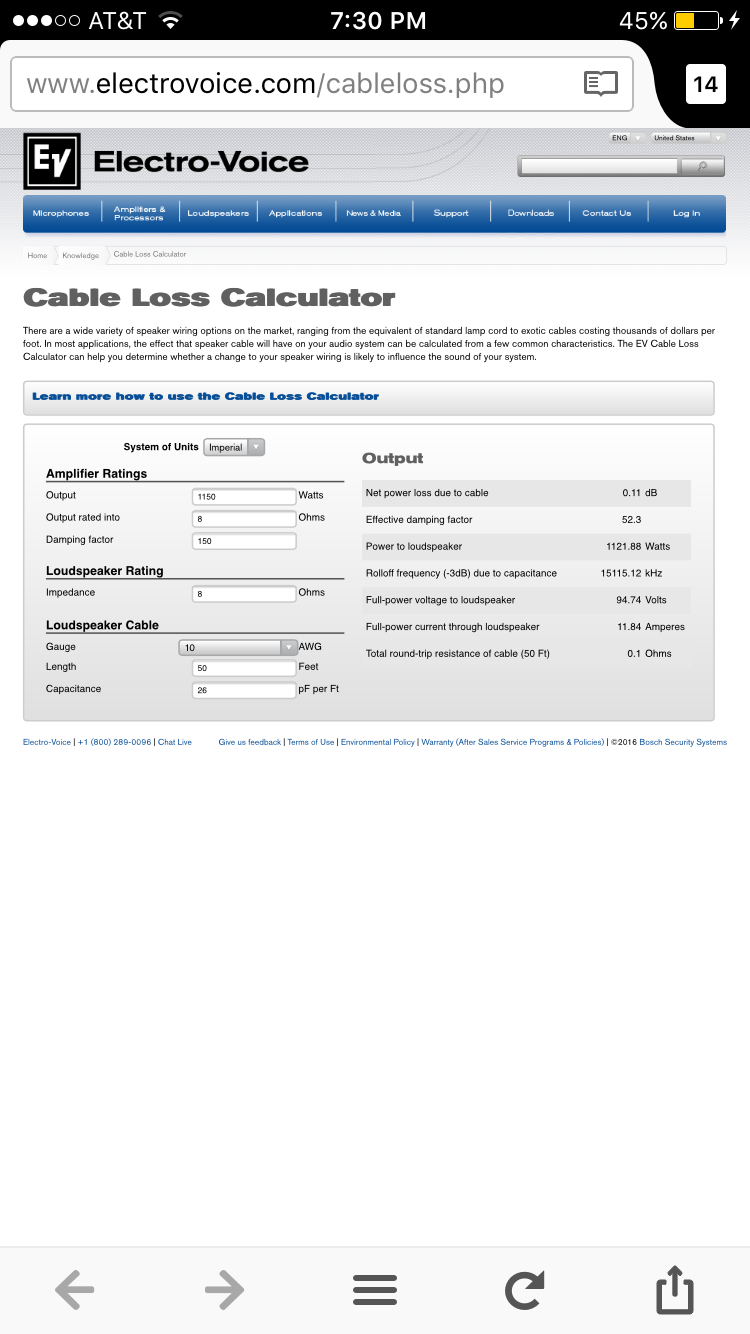

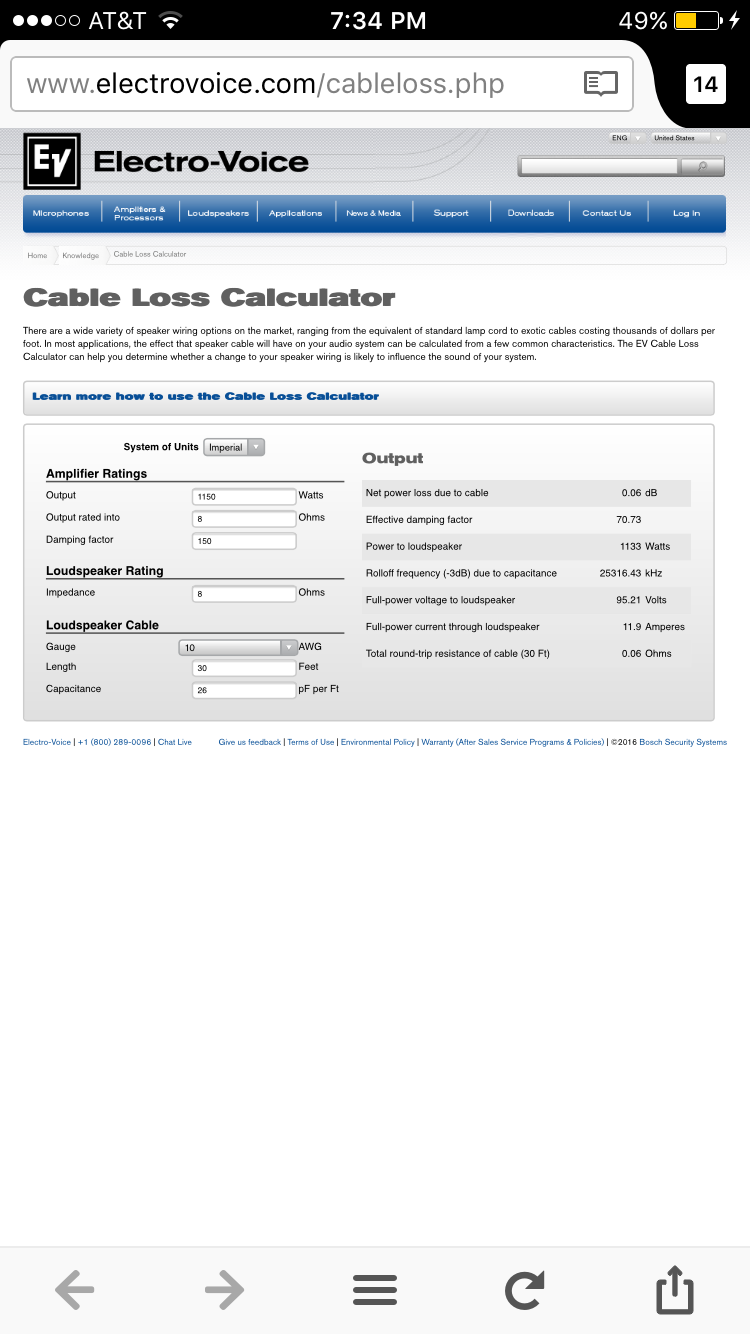

Here is a handy little speaker cable length / loss calculator by

Here is a handy little speaker cable length / loss calculator by the fine folks at Electro-Voice

[[url=http://[/URL]="http://www.electrov…"]E-V Cable Loss Calculator[/]="http://www.electrov…"]E-V Cable Loss Calculator[/]

All you need to add are the amplifier's rated wattage @ whatever ohm load you intend to run, and it's damping spec.

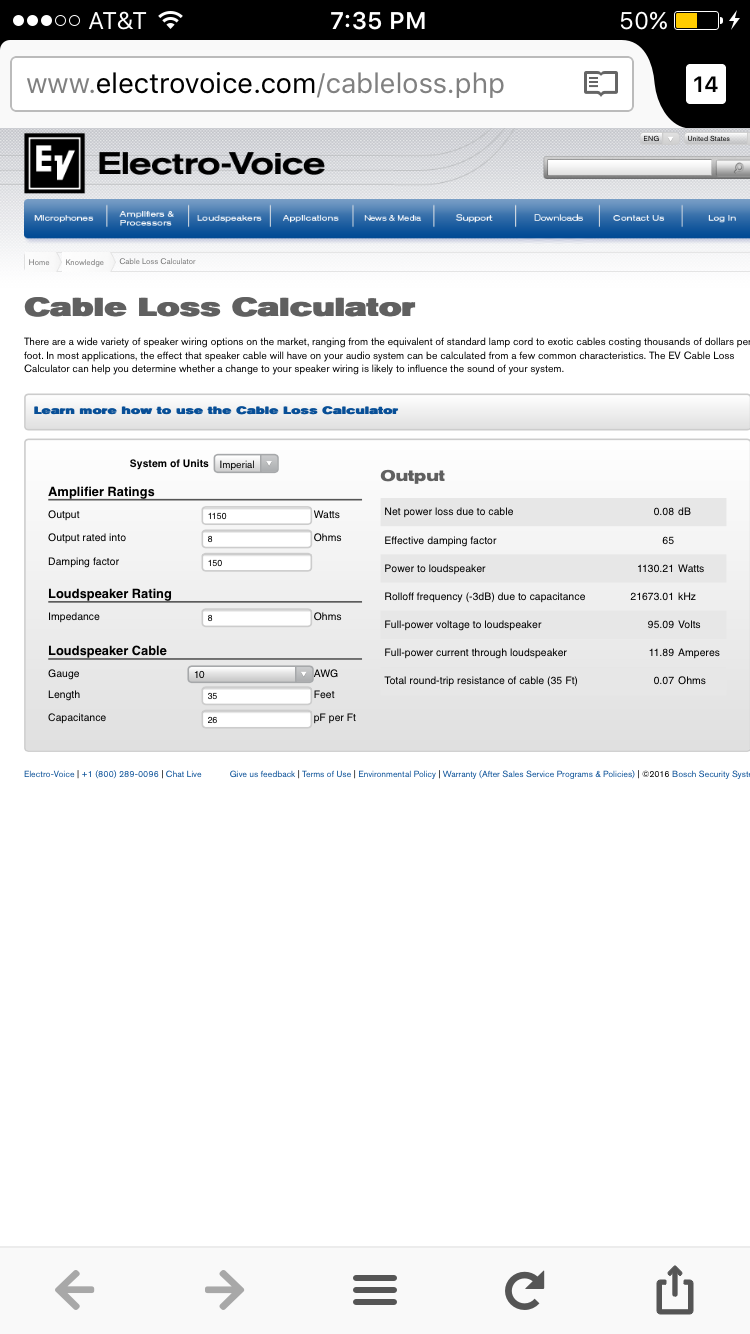

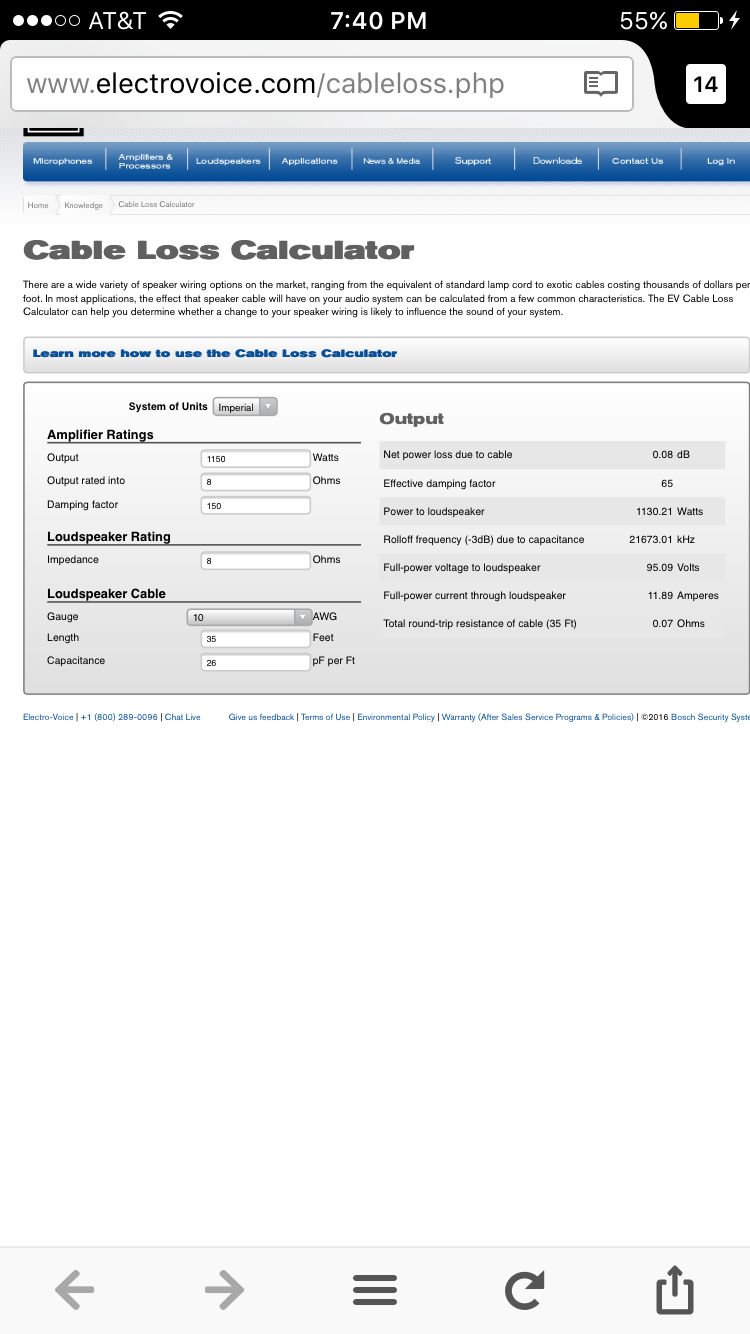

Wow this is pretty crazy! I ran the numbers for belden 10 AWG an

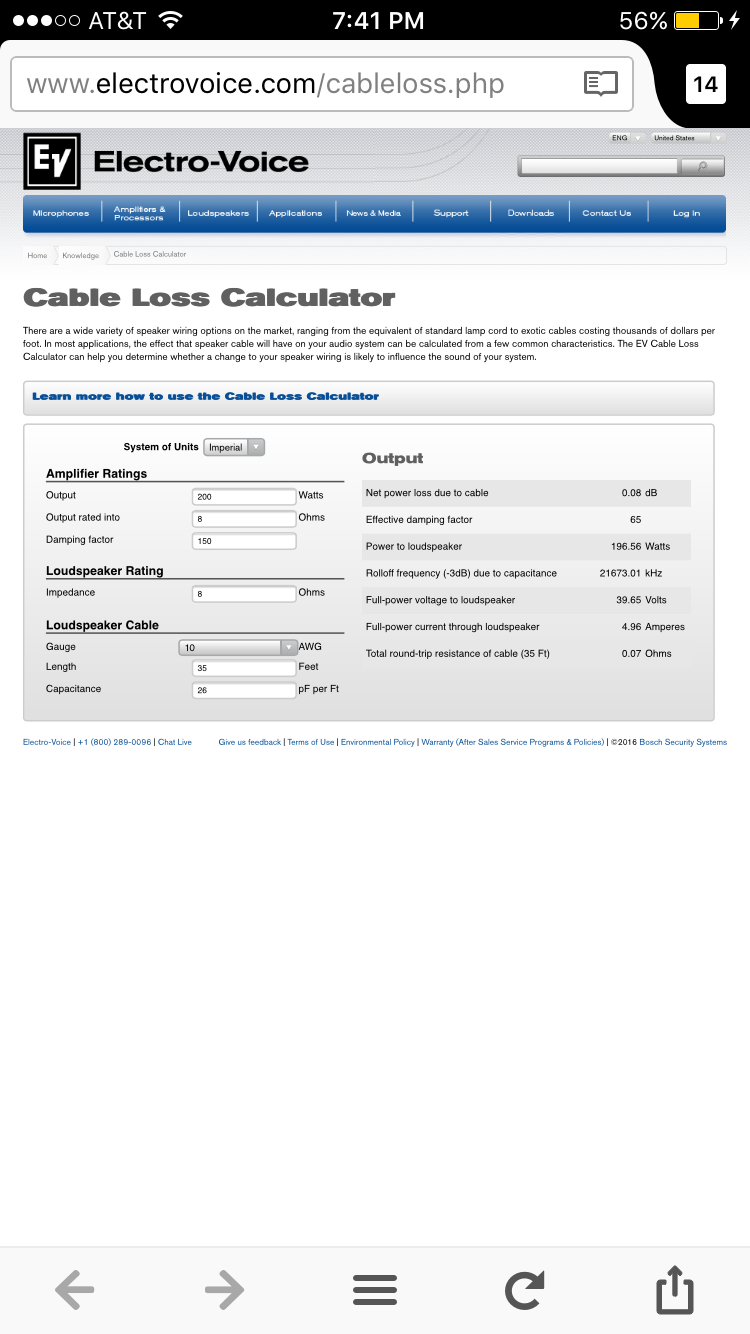

Wow this is pretty crazy! I ran the numbers for belden 10 AWG and over a 50ft run it loses 28 watts of power. Now out of 1150w that's only 1 40th of the power. But I'm surprised that there is even that much. When I changed the run to 30ft it was a 17w power loss. If I change to a 35ft run then it's a 20w power.

That's pretty crazy if the rack was located on say the left rear of a 15' wide room like I initially planned, the speaker getting the "long run" would be the front left, and receiving 20w less! I'm not sure how to calculate for frequemcy in this type of equation. I'm also not sure how to scale it to see how it would effect an 85 db listening volume. I'm also not sure how it scales of I'm using only say 200w of the Max power. But when I typed 200w into the calculator it says I'd lose 3w on a 35' run.

I'm not sure how to translate 3w of acoustic power into db level at the listening position.

My over all guess is 3w difference would be tough to distinguish from 10' away.

But still it's facinating. This could be a contributor to some slight phase / timing errors in a mix. Or maybe mess w crossovers?

I'm not trying to go overboard saying this would be a make or break, or even noticable on its own but those little things could add up.

Absolutely facinating! I really hope I can figure out some ways to apply this data to some useful things. Any insight you guys have on this would be great.

It's certainly made a case for me to keep all stereo/paired cable runs as close as possible. And really I've never minded extra slack but I'm gonna try and tighten up on that. I've always avoided extensions and adapters whenever possible I wonder what type of effect those would have.

Lol the old 50'er made of 10' xlrs commented together seems even more gross to me now.

What it's also done imho is justify electronic speaker compensation and eq Ect as the last 3% of "perfecting" the room tuning. Even speakers placed symmetrically could be slightly off due to these types of things.

I also really need to learn to solder to a good level since a shoddy connection could really effect things.

Does anyone know a way to test that cables are performing identically? Maybe w a multi meter?

Also does anyone have reccomendations for a good electronics book. Either general or audio focused. Or both. It looks like it's time for me to start learning at more than a casual pace.

I may also just be doing an outbuilding on the property instead of rebuilding the basement. This could cost about the same but give me more privacy and better ceiling height.

My recommendation would be to use similar lengths of cable for e

My recommendation would be to use similar lengths of cable for each speaker so the characteristics (inluding losses) are balanced for the pair. For the speaker that is on the same side of the room as the amps, run its cable alongside the other speaker's cable for half way across the rear wall of the room and then come back again. Do not coil the excess length of cable, as that affects the inductance.

Random Notes: If you want to continue on this career path, you

Random Notes:

If you want to continue on this career path, you won't ever regret learning how to solder.

There's a reason the manual only stated, 'use the lowest gauge wire, and shortest cable run.' That pretty well sums it up. Keeping your lengths the same seems reasonable given your measurements.

The efficiency of your speakers will have a lot to say about whether or not a few watts will make an audible difference.

Signal loss at various points along the way is inevitable. You could have 4/0 gold ingot between the amp and speaker terminals and still have some loss. Accept loss/ft as a fact of life and remember that every song, ever recorded (great and terrible) has passed through wire. By all means do the best you can, but don't get stuck in 'paralysis by analysis' mode. The calculations are interesting, but don't fret too much over it. Worrying about 3 watts out of the maximum of 200w is pretty small. If the amp's maximum is 200 watts PEAK, what is it really using most of the time? The amp manufacturers all want that high wattage spec on paper, but realistically run more between 1/8th and 1/3rd rated power most of the time.

Add up all the maximum wattages of all your proposed amp channels, are you planning on pulling. Remember that discussion about breakers? How many of those 1150w/ch stereo amps could you run on one 20A breaker if they were all "balls out" at max power all the time? Answer: 1 (and barely). Before you sweat a 1.5% difference in speaker output, make sure you're not starving your amp(s) for power on the way in. (Again, within reason)

We live in an imperfect world. The good people at Neumann have been making microphones for almost 90 years, and AKG almost 70. Despite time tested manufacturing techniques, world-class craftsmen, and the best materials money can buy - if you want a "matched pair" of any of their top-of-the-line mics (which don't really use very many parts), you have to pay up. Not because they'll take special attention to build 2 that are identical, but because build them all exactly the same, yet they still have to test every one after they're finished to plot their slight differences in specific characteristics - then they select two that tested very nearly the same. So the same is true, to some degree, in every single thing in your chain. Source, Pre-amp, Pan settings, Amp channels, Wire, Speakers, Room Construction, (your ears) will all introduce some fractional differences. None of those things can eliminate error/variables completely, the mark of a quality manufacturer is how much they can minimize it.

Using networked powered-speakers is looking better and better, isn't it?

dvdhawk, post: 440464, member: 36047 wrote: How many of those 11

dvdhawk, post: 440464, member: 36047 wrote: How many of those 1150w/ch stereo amps could you run on one 20A breaker if they were all "balls out"

It's pulls 43A at 8 ohms. Lol. There's no plans to run these full tilt, ever. Just want headroom and good transient response. Maybe when I have a 400A industrial power service I'll do it for fun!

dvdhawk, post: 440464, member: 36047 wrote: You could have 4/0 gold ingot between the amp and speaker terminals and still have some loss.

Forget speakers and amps, I want a gold ingot!!

dvdhawk, post: 440464, member: 36047 wrote: Using networked powered-speakers is looking better and better, isn't it?

I still don't think so. Then I'm running a bunch of power cables which aren't cheap. And still running audio lines seperate from the power isn't always easy from a logistical perspective. The amps have built in dsp for all the tuning as well which I can save various settings for entertainment and flat.

I'm open to suggestions on cinema speakers that do this as well as being powered.

The line loss stuff is just part of the game. I'm just facinated how much it actually is.

Overall it seems the most efficient way to do this is to located the gear centrally left to right and either close to the power panel, or speakers, near both would be ideal. I like the idea of the rack towards the back side of the room near the power because it makes sense given then pre amps and guitar stuff all goes there too. It keeps the front side obstruction free and the analog knobs and plugs acessable.

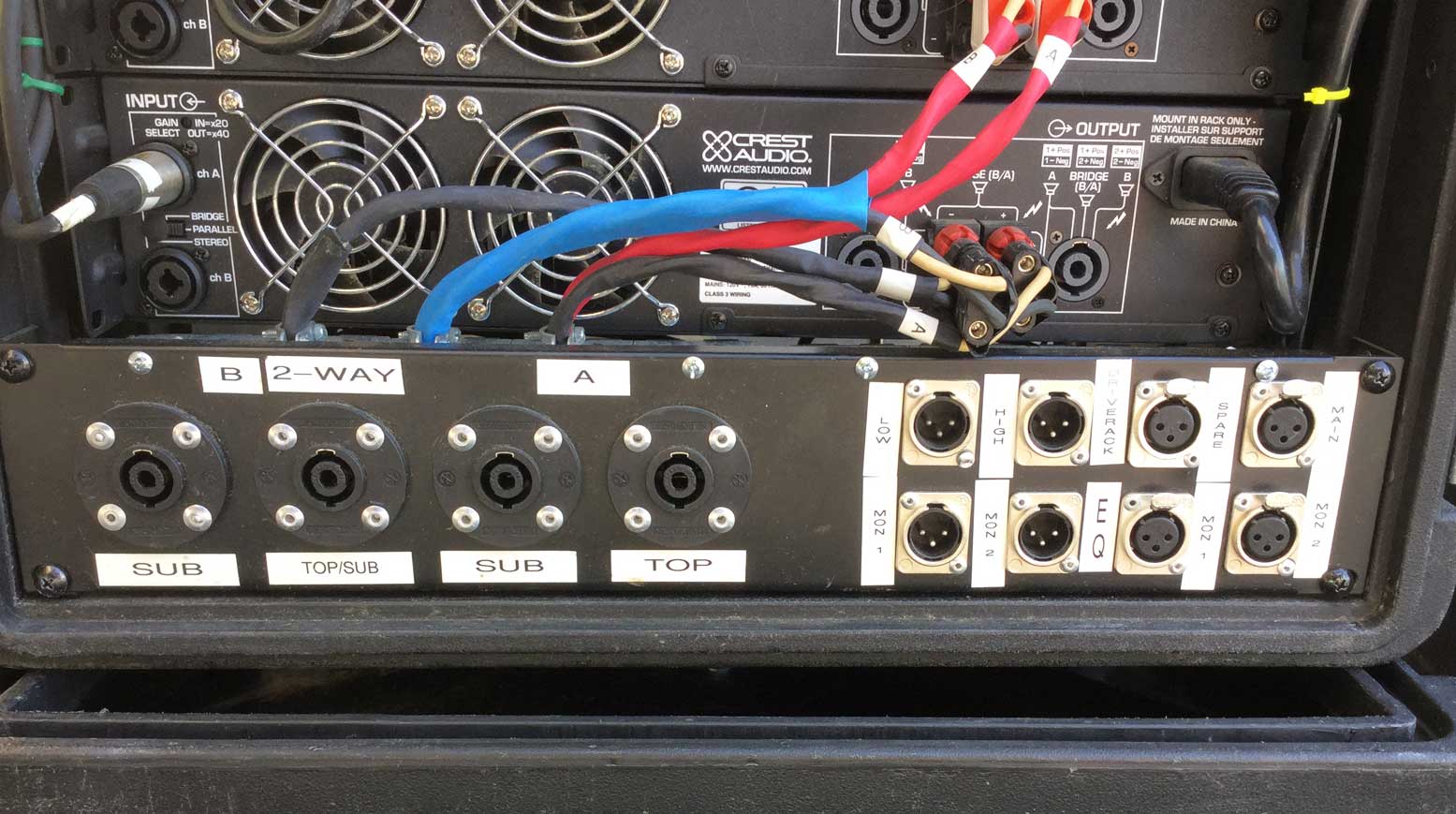

dvdhawk, post: 440383, member: 36047 wrote: For my current live

dvdhawk, post: 440383, member: 36047 wrote: For my current live rig, some of my cables avoid the 4-conductor "twist" completely by terminating the stack-side with a breakout box that consists of a single gang outdoor type water-proof box, a beefy water-tight cable connector, and a stainless steel wall plate with 2 SpeakOn NL4 panel-mount males (one for sub / one for tops) soldered onto the 12/4 - then I use 10ft. and 5ft. SpeakOn cables to drop to the breakout box. (quick, easy, durable, scaleable) There is always insertion-loss when you add another connector in the path, but it's very minimal in this particular real-world application. [I can post a picture if that doesn't make sense]

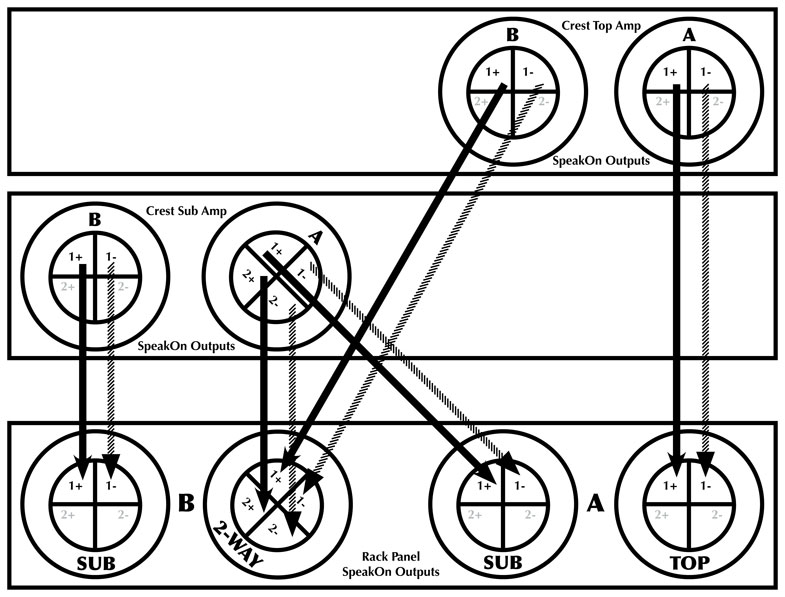

Hey Kyle, I was out loading up the medium-size system I need for tonight and grabbed a picture of the breakout box / cables I was trying to describe, and saw that the 4-conductor cable for the 30ft. run isn't 12/4, it's 11/4. The short sub jumpers are 11/4 also, and the top jumpers are 12/2. 11AWG just barely fits in a SpeakOn.

With this system, there's just one amp rack behind the stack on my side. For the near-side, you just need a sub jumper and top jumper directly connecting JBLs to a panel on the back of the rack, through 2 panel-mount NL4s. The 30-foot 11/4 feeds from a single NL4 in the amp rack and runs to the other side and breaksout to 2 panel-mount NL4s at the box, with identical cables to jump to the sub and top cabinets. I have the rack panel wired up so that you can connect that 30ft. 2-way to a single NL4, but there's also another NL4 wired to the sub amp so I can run 4 discrete outputs [sub/top/sub/top] if I'm doing the double stack on one side for a bigger gig. Nothing needs to be rewired, or reconfigured at the job, just plug into the right place.

Meanwhile, on the same rack panel, there are 8 XLR ins and outs to handle Mains and Monitors, and like I said earlier, if I'm running a bigger system, I double-stack both sides, and run another identical rack of Crests (minus the DriveRack) on the far-side, and have 50ft. (or whatever) XLR feeding it. I just use one dbx DriveRack in the near-side rack with the spare outputs wired to panel-mount XLR males, that feed the hi/low amps when I send to a far-side rack like that.

In one of the littler systems, I've done away with the need for the breakout box, by building the same capability into the Clair Bros. sub cabinet. I run 10/4 from the amp to an NL4 on the sub, and then inside the sub I breakout 2-conductors for the 18" sub, and send the other 2-conductors to 1+ and 1- of another NL4 to act as a thru to the full range cabinet. You just need to be sure you connect to the correct NL4, so they're color-coded and labelled. It only eliminates one cable, so I'm still considering using a 30ft. breakout like the other rigs, to keep them all exactly the same.

Dude thanks! That diagram is super helpful. 11awg huh!? The plo

Dude thanks! That diagram is super helpful. 11awg huh!? The plot thickens.... Lol. Or is that the wire that thickens?

Love crest amps man! There one of the few pa style amps that have a bit of 'character' to the sound. I loved the rack of crests at a club I was at for a couple years. Coincidently they had jbls plugged into them too.

Having multiple plugs wired as you described might make sense since I'll be expanding the rig over a year or two and the amps will be doing different duties during the process. The time consuming part has been grouping the purchases on a spreadsheet so the system runs to spec the whole time, costs stay within budget, and there's no waste during the whole thing. I've got 3 out of 6 purchase order/groupings done so far. There's a few combinations that work so time will tell.

Also I've decided on doing an outbuilding according to one of sepmeyers room ratios. It gives me 10' ceiling height, and the ability to have a 2ns floor loft to sleep in, and a bathroom.

At not a whole lot more cost than re doing the basement, space gives me better isolation and seclusion, and the loft doubles my sqft.

Oddly, now it's the center channel that's become the longest run lol with the rack centered in the room 2/3 back. So it's cost me about an extra 5ft/$5 per cable roughly on paper.

This center channel thing has been the pain in the butt the whole time, from odd channel counts 3 vs 4 to the speaker run thing. It's been quite a bit of work keeping things efficient w no wasted stuff.

If I have some troubles soldering the 10awg on the NL-8 (the steel ones rated to 10awg) then the 11awg wouldn't be much of a compromise technically and would save cash both in connectors and potentially cabling.

What brand is the 11awg just out of curiosity?

Thanks again for thinking of this thread and snapping the photos! Good luck on the gig!

The 11/4 was made by Dayton (Parts Express), but they don't seem

The 11/4 was made by Dayton (Parts Express), but they don't seem to carry it any more. ProCo still sells 11/4 for portable use, but I don't think it's rated for in-wall use.

I just soldered some NL8 panel mounts last week for a project, it wasn't too bad. I stripped the wire, brushed a little liquid flux on the bare wire, crimped on a spade connector, slipped about an inch of heat shrink up the wire, slid on the spade, dabbed it and the NL8 tab with liquid flux, and when I heated it up [100w gun, for this one] - the solder wicked into the bare wire, and all over the spade and tab. The result was a really solid (literally) solder connection that was a lot easier than soldering the stranded wire straight to the tabs (which I've also done recently where I didn't have the depth). A light blast from the air compressor cooled it off quickly, and then after all 8 were done, it was time to heat shrink the tubing over each spade/tab. The biggest problem I had soldering stranded 12awg wire straight to the tabs, was holding the cable in place while the molten solder was still a liquid. I was holding it with my bare fingers, and it was getting really hot. If you grab it with a tool in a situation like that, it's probably going to melt the insulation, so a glove might have been useful. If you have enough depth behind to crimp on the spade, it holds everything in place while it's hot.

Thanks man, I didn't even think of using a spade conntector. Wh

Thanks man, I didn't even think of using a spade conntector.

When I do the real things I'll keep in mind what you said about holding them. I'll probably have to make some sort of a jig / clip setup to hold everything firmly in place so I can have two free hands. Maybe some sort of adjustable pipe clamp or c clamp, with glove leather glued to the contact points would hold it with just enough pressure and disperse some heat to prevent messing up the jacket. The standard 'helping hands' things from the hardware store are meant for burly wire like we're talking about. And would like you aside likely mess up the rubber surround.

I've still got to figure out if being run behind an acoustic baffle wall is technically 'in wall' from a code perspective.

In a lot of cases, the spade connector would be sufficient. Nor

In a lot of cases, the spade connector would be sufficient. Normal SpeakOn panel mounts take a 3/16" disconnect, and the UC versions (for higher wattages) use ¼". I don't want them ever coming off, so I solder both the crimp and the spade to the tab.

I might normally use hemostats, or large metal parts tweezers (sprung to stay closed, instead of open) to act as a heatsink, but in this case I'm trying to keep the bared wire to the exact size of the tab, so there's no copper left to clip them to. I heavily tin the wire, and the tab, let them cool down, then heat them up quickly and add enough solder to give a good connection. I'm usually not a big fan of the 100w soldering gun, but for this size of wire I think it's a better choice. You could get it hot enough with a typical 25w iron, but I think it would take so much longer you'd end up with more heat build up on the parts, and actually be more prone to melting something. Hitting it very gently with the air-compressor, until the solder solidifies is a good way to keep them from getting crazy hot. Once it's solid, you can blast it with more air directly.

They do make screw-terminal panel mount NL4s, but not NL8s. The cable ends are all screw-terminals, with some of the older variations using an allen wrench.

Looks like I've gotta practice soldering since the NL8 is the on

Looks like I've gotta practice soldering since the NL8 is the only connection used in the qsc cinema speakers.

I've had this soldering iron in my cart for ages now waiting till I had a spot to do electronics. Looks like my tool shed should be up by the end of the month and I should have a little electronics bench. Do you think it'll be enough? It's variable temp, but 50w. It's not inexpensive so I figured it would be my go to general purpose soldering iron. Do you reccomend something specific for the NL8s? It's gonna be a while till the big system comes, probably about a year and a half. So I'm open to options. If I can get one that's sufficient for the NL8 right off the bat That's cool. Looks like the 95w weller is $350 and the 200w is $500. Like usual I'm not super afraid of prices, they are what they are, just wanna make sure it's the right purchase. That said 350, seems to sting less than 500, but if it leaves me undergunned for certain things it paying the full 500$ for the 200w makes sense.

The soldering iron I was considering from hakko the fx-888d was 70w and $100. Perhaps that's the best starter, until I have onfficial bench?

bouldersound, post: 440833, member: 38959 wrote: I just saw a We

bouldersound, post: 440833, member: 38959 wrote: I just saw a Weller pistol grip iron at the flea market for $10. Should have picked it up.

For sure man. That was a diamond in the rough. Weller has a longstanding reputation for good quality and reliability, and they are priced accordingly.

I've did it of research on hakko vs weller a while back and it seems that hakko is a bit more popular and trendy, probably due to its lower cost and higher wattage. This would be at the expense of long term durability and overall build quality vs weller. Some people had some QC issues w hakko, where weller seemed not to have those complaints. That said it seems weller just like most things has cheapened a bit over the years and perhaps not quite as robust as they were a couple decades ago.

You can't go wrong with any of the Wellers. Try to get one that

You can't go wrong with any of the Wellers. Try to get one that has a replaceable tip that is easy to find and get a couple spares. I use a conical tip mostly, but the chisel tip is useful for some situations.

I need something I can throw in a tool case, so I have multiple pencil type irons of different wattages/temperatures ranging from 12w to 60w. I haven't used my desktop "soldering station" in quite a while.

And then I have the big stupid Weller 100-watt gun for heavy duty jobs (including using it as a heat-knife in the ICF foam.) I remember as a kid watching my dad trying to solder delicate little things, like slot-cars, with a 100-watt gun (and probably big, thick plumbing solder). He was an amazing machinist / mechanic and could fix, or build, absolutely anything. But with the wrong tool for the job, it always ended up in frustration and a blur of cuss words. There probably wasn't anything else available in any of the local hardware stores back then, but he might as well have used a oxy/acetylene torch.

Lol about using the wrong tools. I learned that through my own

Lol about using the wrong tools. I learned that through my own cuss words and balancing acts. Still can't find anything bad about weller it seems. I'll probably grab another cheapo radio shack pencil type for the short term so I can swap in a pickup for a new guitar. If I can get the weller station right away I will but I'm diggin a bit deep into my pockets trying to get the last of the computer drives and software, so radio shaft it might be. Maybe I can find a weller pencil type on sale I think they're around $30.

I'm excited to finally have a chance to use all the soldering based tools I bought last year, just need to grab a soldering iron.

If the 50w station can't handle the NL8's I'll

Know to budget for a 100w gun.

I'm hoping these last 4 cables I've got on the list to get me up and running w the new interface and guitar are the last. I've already specd out the canare wire and switchcraft jacks I'll be using for cables.

Part of the reason this whole thing is taking so long is i don't wanna get started without the right toolset and software set. My computer is nearly 9 months old and hasn't been taken out of the box yet... I'm getting antsy. The good news is it's still the best bang for the buck computer out there as far as I can tell. Ditto for the laptop.

I've decided on a zed 14, for a summing mixer which will be phase two of this interim rig after all the software is in, and my old stuff archived. I'm even gonna send a reel of tape out to a real mastering place for transfer after I do it on the Rosetta at the studio!

In the meantime the laptop will be perfect form web design and sketchup duties and possibly video editing depending on how occupied the desktop is.

Can't wait to start making my out mics and pre amps and eqs soon!!

Cables first tho lol.

This that SpeakOn / XLR panel on the amp rack. This rack is sti

This that SpeakOn / XLR panel on the amp rack. This rack is still using banana plugs out of the amps rather than SpeakOn, but I intend to update that in the very near future. Net result though, it's wired just like the diagram.

For the smaller set-up [a JBL SRX728s & a SRX722 run in full-range mode on each side],:

The "A" stack on my side gets short jumpers straight out of the A-side "Sub" and "Top" connectors.

The "B" stack on the far side, plugs that 30 footer shown in the other photo into the jack marked "2-Way Top/Sub", and 2 short jumpers at the other end. The B-side "Sub" jack doesn't get used in that configuration.

If I'm going up a size and running 2 of the JBL subs and 2 of the JBL tops per side, the stage is probably a little bigger too. In those cases I send the "High" & "Low" out of the Driverack via XLR to the far side to another rack with 2 identical Crests, and use the "Sub" & "Top" jacks with short jumpers for both A & B all around. Theoretically, doubling the cabinets should gain you 3dB and doubling the power should gain you 3 more dB.

If I really needed to squeeze a few more dB of performance out of either of those JBLs, (which I don't) I could bi-amp the SRX722 with a flip of a switch, and/or power each 18" driver within the SRX728 separately with an internal jumper change. The Driverack would support going stereo 3-way, but each of those additions would require adding another amp to bigger / heavier racks. Bypassing the JBL's internal crossover, and putting an appropriate small amp dedicated to the horns, would eliminate the power lost to the 722's passive crossover (which is a way-above-average design btw). But we're not kids anymore, and not looking to break our backs, and were never trying to make people's ears bleed even when we were kids.

I was lucky enough to hear a touring band that came through one time using the exact same JBL speaker set-up, except they bi-amped the tops and had about 39kw of Crown iTech power (and needed 80-amps of 3-phase 220v for sound). The speakers sounded amazing at the back of the room. they were all IEM, and their stage-volume was very quiet - so everything you were hearing was coming through the FOH PA and it was impressively loud (118dB peaks) and crystal clear. It was fun to hear what my speakers would be capable of, if I had that kind of budget for amps, but I'm so past the point of wanting to drag 220 cable around again.

There used to be a dual graphic in this rack for Mon mix #1 and Mon mix #2, so that's why there was routing on the panel into the EQ and back out to the Crown Monitor Amps mounted in a different rack. (It made sense at the time).

I know I'm repeating myself, but I thought the photo might explain it better.

Yes excellent stuff hawk! A good buddy of mine uses the srx's an

Yes excellent stuff hawk! A good buddy of mine uses the srx's and he's doing quite a bit of national touring acts.

I love that bands are doing iem's more and more now.

Driveracks are awsome! Love those things. The parametric eq sounds good too!

I love how neat and orderly your rack is, while also leaving so many options open!

Less gear of better quality always seems to be better in all aspects. And pays for itself either upon sale or through use.

Live sound changed for me about 5 yeas back when I saw Hubert Sumlin (rip). It was in a theater circa 1930s and the live sound guy had a line array, one 4ft rack and a Yamaha CL-9. It was absolutely stellar acoustic quality. Like studio level sound. Between the amazing Acoustics at the theater, and the good comercial sound equipment, it was wonderful. That and the performance itself. It just surprised me that it was a 10k console, and very little outboard.

A few years after I used a Yamah lsr console and even thought it was being Fed from a presonus studio live console steroe buss, the band had never sounded better overall that quickly. Only ones or twice did I have them sounding better. But using the Yamaha console even though it was older, was a sure step above the rest.

How long do you expect to run the system wide open at a time? Pr

How long do you expect to run the system wide open at a time? Probably not more than ten seconds and probably not more than once or twice in your life. So all that speaker and amp capacity is mostly there for headroom to accommodate occasional high peaks. Given that and the short runs 14AWG lamp cord would probably meet the electrical requirements. Point being that any of those listed products will perform well enough so maybe focus more on things like meeting code (for in-wall), cost and ease of assembly. I suspect 10AWG is over kill and may be harder to use with the connectors.

In my live rig I ran near 1KW on 100 feet of 12AWG all the time without the slightest problem.