Ill try to make this short.

My wife and I just moved into our new build house. I am wanting to construct a home studio in the basement that can later be a nice man cave and/or home theater for the next buyers.

I read through Rod Garvais' book, and it seems a little over my head, but there are good points that I could take away from it.

I am liking the idea of using resilient channel and two layers of 5/8 GB with green glue on my walls and the ceiling, but how much Isolation is that going to give me? I know that I am supposed to put 5/8 GB in between my joists, but that seems excessive and I'm not sure if my floors load can handle that. I do have 9' ceilings in the basement, so I should have enough room to build a ceiling on my walls. I guess I just want to know how much isolation I will get with that setup? I dont need it to be dead quite upstairs when i'm thrashing on my drums down there, but enough iso so I dont annoy my wife and kids would be nice.

Thanks,

Comments

figured id mention it takes a doubleing of mass (drywall) each t

figured id mention it takes a doubleing of mass (drywall) each time to gain 6db in sound attenuation (isolation). so you go from a single layer to double, your wall got six db quieter. you now have to add an additional two layers (four total in all) for that next 6 db.

so if your single layer wall is stc 30. you add a layer of drywall, now its stc 36. now you add two more to that (four total) your wall is stc 42. to get to the next 6 db or stc 46, youd need to add four more layers, (making 8 total).

if 12db is an apparent doubling or halving in volume, you see how much mass and money these things can take. this is because the DB scale is logarithmic, not linear.

this is where your independent/physically decoupled ceiling does so much for you. there's an 'extra' 15 db or so in isolation, right from the get go, compared to channel based alternatives. and its cheaper, an easier to work with.

Dude, thank you for the reply!!! That is exactly the response I

Dude, thank you for the reply!!! That is exactly the response I was hoping for.

I would love to have a pro, or Rod , to collaborate on the design to make sure all is well. Is Rod still doing design stuff? How would I contact a pro or Rod? Do you know a round about price they would charge for design? I assume its pricey...

My builder framed out the living section of the basement when the house was built, so down the road I could easily finish it. Well after opening this can of worms....I fear the $1500 I spent on the framing was all for not! lol

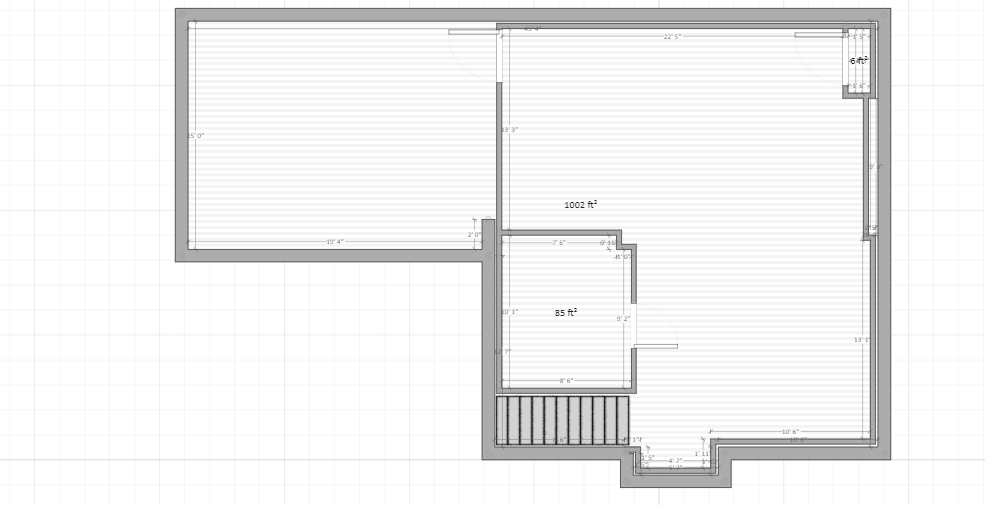

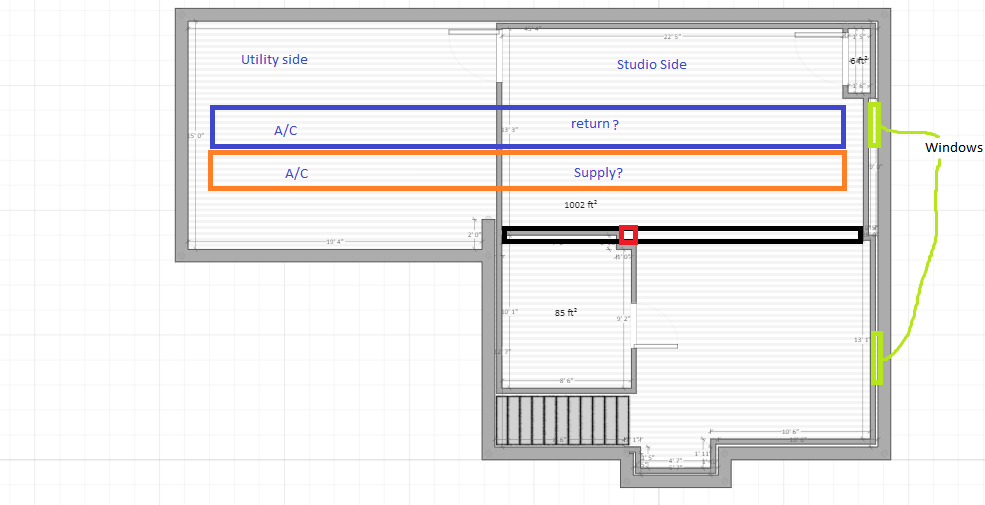

I'll attach a rough cad drawing I made of the basement layout. Note that the sectioned off room is for a bathroom, although the walls are not framed for the bathroom, only the outer perimeter walls of the basement.

Also, the ceiling height is 8' 6" from the floor to the bottom of the joists, so not a true 9' ceiling.

There is a post in the room and a beam which I can highlight, along with the A/C ductwork.

Thanks again for the taking the time to answer my questions. It is much appreciated!

hey man, nice sketches. I haven't talked to rod in a couple yea

hey man, nice sketches. I haven't talked to rod in a couple years, so I'm not 100% sure my contact number is even valid. probably 6 years or so by now, I had searched around for his info on the web, and came up empty. so I sent him a pm via this site, which he responded to, and we spoke a couple times over the years on various projects I had, when I reached certain dead ends, or need to be completely sure. his rates were affordable for anyone whos doing a specialized project like this. there was like a day rate, and it depended on if he had to travel or not. not trying to dodge the question, I just cant answer it with any accuracy, since its been a while, and in my case we had a couple consultations, I wasn't lucky enough to have him plan them. as an aside, I will be contacting him probably in the winter to actually plan a couple of personal projects I have for myself (home mastering room, mobile recording trailer). so I'm hoping his contact hasn't changed.

as far as the walls you've put up, all is not lost. if you decide to incorporate them as part of the studio, you just shorten the studs, put the headers back on, and now they aren't touching the ceiling anymore. add ceiling joists or sway braces/iso supports, and at least you've not lost on materials. if you or your friends are handy in the least, you can probably handle some or all of it yourself(s) and come out equal financially, and ahead acoustically. if it were me, id so that anyway, since essentially cutting them down a couple inches increases isolation potential so drastically, its plenty early in the project, and they'll be plenty of carpenters in and out.

the carpenters who framed out the theater project had to do just what I described, when they built the first iso wall without enough clearance for the fire blocking. probably took about two hours or so for them to take it apart, trim, and, re assemble the partition. not the worst error when caught early. also exactly why we started with one of the smaller iso rooms (equipment, and amplifiers/isolation) as far as the framing and ceiling clips went. making the mistakes in the small section, helped the guys flow smoothly in the other 900 sft.

so with a little elbow grease and/or bribery you can probably actually benefit from this, since you've already got something to work with.

the funny thing about these independent wall (and ceiling) partitions, particularly the walls, is you can just move them around. at one point we had several walls framed and temporarily attached, then just stacked them aside, while the electricians did they're work. way better than having them work around the walls, and the carpenters were only available when they were. so it was like big wooden lego blocks.

also, even if you left that room alone, it could be a perfect storage room, and/or machine room, since you've got the bathroom covered already. that said, having isolation in this area opens it up for a guitar cabinet, or a vocalist for demos while having the drums going, ie live tracking. one booth I built was 2x6 inner shell 2x4 outer, with 3 layers 5/8 inside. 2 outside, slanted walls and ceiling, and a window. all built like the drawings in the book verbatim. 3' away is the house drumkit (Yamaha maple) and the mics don't pick up drums ion the booth. even the condenser mics. you can still hear the drums a with no headphones on or anything going, but just the drums, but its fairly quiet, and nothing on the mics. believe me, we tried, we wanted to know what it could or couldn't do, before we were in front of clients... so anyway, useful isolation can be attainable fairly close to a drum kit.

you've got every advantage because its all wide open, and your smart enough to plan.

I highly recommend rod, simply because ive dealt w him, and his book had a huge effect on my career and life. I'm not sure he'd remember me by name, or even at all by now, and I don't know if he'd like me giving his contact out. id try PM ing him. other well respected acousticians, who have readily available contact info, are John L Sayers, in Australia, who has a great forum build diaries, and John H Brandt (hope I spelled his last name properly), who has a great portfolio, excellent set of acoustic tools, and seems a genuine good, and talented guy, which is rare sometimes. Andre Avare is another human wealth of knowledge, I believe he is an acoustics expert by trade, and certainly generous on the forums, I'm not sure if his contact stuff is online, I believe he's out of Canada. I would offer my services but I'm currently on a hiatus while I build a brand new remote recording rig, and a studio of my own from scratch. so I'm not far enough into those projects, to do the drawings and spreadsheets, ect, ect, I would typically do as part of my professional services. ive spent countless hours obsessing on acoustics and continually those Gents have come up, offering insight, generosity, and they remain well respected by their peers. I haven't talked to any one of them about their rates.

beyond that there's basic things like budget, your location, your primary intent for the room, other possible down the road considerations, ect, that youll want to have defined for when you talk to an acoustician. once that's done usually its narrow out the floor plan, get the wiring and lighting and hvac, then the acoustic treatments, then supply list, drawings permits, then build. it'll take longer than anyone wants, but be more rewarding than anyone could imagine when done right. theres no cheap way, but certainly efficient ways to get your intended result without breaking the bank or leaving things unfinished. the mistakes ive made in the first studio I built for y cousin in his basement, are still alive and well, they don't disappear. the same however is true of the correct things, they remain working properly. its rewarding still, years later, to walk into those rooms I built after that, knowing nothing was left to 'good enough, nobody will see it'. it truly makes the downright exhausting process worth it in spades.

to be clear is the hvac from the drawings already installed?

Thanks again for your awesome reply! Yes the HVAC already exis

Thanks again for your awesome reply!

Yes the HVAC already exists. I'm not sure though if the unit is big enough to split off of for runs to the studio. Not even sure if that is possible.

Luckily my brother in law is quit handy with this stuff. He even finished his basement in his old house. My main problems are the things I'm unsure about, this is where a pro would be a big help. Things like- load ratings, fire traps, room size and placement, is my cement floor capable of the load from a structured wall/ceiling? These are the things I havent a clue about. I do know that I would hate to have to rip up the concrete around the perimeter to pour some footers...cause I have PEX in the concrete for future hydronic radiant floor heat, and I dont want to ruin the PEX.

I'm no pro engineer, so I dont know how crucial it is for me to have an 'ideal' room layout. Like, my room will most likely be an 'L' shape, is that bad??? Would it be better to put up another wall and divide the 'L' into two spaces? I would rather not, just in case we end up selling this house down the road, that space would be more beneficial to someone else if it was one big room I would assume.

From what I gather/read most things can be controlled or 'fixed' by acoustic treatment, but I dont know what I need/should focus on...or whats more important. If I've learned anything from Rod's book its that everything is the most important. Thats why I say this whole thing has turned into the can of worms. Of coarse I have opened it, and now there is no going back, or half assing this.

I guess I will PM Rod and see if I can get in touch with him. What is his forum name?

Thanks again.

i know the can of worms you speak of sir. fresh out of college,

i know the can of worms you speak of sir. fresh out of college, I bought the book to make a little demo studio for my uncle/cousin,and ten years later I've turned into a professional engineer, and worked at/rebuilt a studio that has had hits before and after my work, so you never know. that can may go deeeeeep.

one of the best things you can do as homeowner/project manager, is fill in the important details that contractors may otherwise overlook, deem unnecessary, or incorrectly. this saves money, aggravation, and gets it done properly, without question. take caulking perimters gaps for instance. super critical, in the USG Sheetrock install manual, never gets done in the field. its something that would be deemed 'custom' and priced up otherwise. this is a perfect light duty job for homeowner and friends/family. ditto for insulation, running wires, ect. over the course of the different projects I gradally moved away from doing every single part myself, and started using framing contractors, glass guys, and electricians, after I had a grasp of it all myself, hands on. what I found was me taking care of the details, and unorthodox / acoustically specialized parts, really worked well overall. it let me inspect work without being obnoxious, let the workers do what they were familiar with, without having them waste time deliberating over new techniques ect, and it made sure for me and the studio owners things are done according to the plans. it became a nice way to be a middle man, without stepping on toes, and still earning my keep beyond just the drawings and calculations.

definatly want a pro for the hvac design / verification, but hopefully your like most houses and the condenser unit has plenty of room for expansion. its a key place for isolation techiques too, both framing, and the ducting itself.

as far as your slab your gonna have to stick within the limits, but what ive found is rods book doesnt seem to suggest or picture things that would be out of typical us residential codes/weight bearing. so in a very general sense in the new england/tri state area, your probably gonna be able to handle as far as load bearing something like a 5-15psf dead load, and 30-50psf live load on the existing structure, which in general gives you2-6 layers of 5/8, very generally. the real calculations take into account anything that weighs anything, but my number crunching shows this to be true in general. again I a very general sense, a typical reinforced 8" slab on grade should handle some 2x4 or 2x6 walls, and 2x6 or 8 ceiling resting on them. along with a few layers of drywall. again that certainly needs to be professionally verified case by case, I think the stuff described in the book is relatively 'standard practice', and typical of appropriate design for a typical house.

most of the channel systems have a 2 layer capacity, and the risc clips / hat channel system supports 3 layers.

layout is super important, has a definite 'right answer', and is free to play around with, both on paper and in the actual room. its a fundamental part, and worth the time. like the stairs could be super useful to have and the layout would want to make sure it complements that, or if it is a compromise, its a compromise instead of surprise. or are people walking in front of the kit or screen every time they go in and out of the room? foot traffic is a big consideration.

acoustically its all determined by the size proportions of the room, and rooms are generally graded by how well the bass responds, or not. so in a general sense the cubic footage of bass trapping would remain the same regardless of layout. same for the square footage of mid/high absorbers, although the location, and mounting techniques may vary depending on layout.

acoustically, logistically, financially, and likely re-sale wise, one larger room is better. so your on the right line of thinking there if you ask me.

as far as shape of the iso shell, rectangle is the way to go in general. the acoustic walls/treatments are usually what's angled, but the drywall walls behind them are rectangular. this holds true for most studios on any level. its easier to calculate (or actually possible, where slanted walls are not technically), its common to build for the builders, it maximizes cubic footage, and just overall right to the point.

incorporating thelarge variety of nooks and crannies of an of existing structure that cannot be modified, is were a pro takes ten minutes to turn into a useful design aspect, and a novice wastes time, money and opportunity. often little alcoves, closets, L shaped parts, are great places for bass trapping, or storage, or amps. in your case Glen, it really depends on if your primary focus is on recording / mixing, jamming with buddies, making demos, practicing.... ya dig? that's what will really define the prerequisites of the acoustic design and layout to a reasonable extent. it helps design the room for you.

I like how you said '...everything is the most important', I might just use that one sometime. it couldn't be more true.

rods name here is just rod gervias, it should come up, or I should say did, last time I tried.

overall you seems to be in good shape, nothing major so far has been mentioned, that's a road block or real bummer. I'm certainly enjoying being along for your journey here, and theres others here with invaluable input, and experience as studio owners whove had pro rooms, or cats building them themselves. its always refreshing to see projects where the questions are asked before the thing is built. its amazing how many times that's done backwards. cheers.

Thanks man! well right away I think I have run into an issue. I

Thanks man!

well right away I think I have run into an issue. I believe my concrete slab is only 4" thick, as apposed to your 8" thick assumption. I'm assuming that that will not be able to supports walls and a ceiling? Maybe I'll have to go the hybrid route Rod talks about in the book, flouting ceiling with J-hooks into the above ceiling to help lighten the load.

You mentioned that the stairs could be fun to incorporate. I thought that I would have to isolate the stairs from the room cause the stairs would be a major 'leak' area??? I would love to not have to build/isolate the stairs, cause that would open up some more design parameters.

Anyway, thanks for collaborating on this with me, and love reading your replys. lots of good info and background!

Hey man, sorry for the late reply, I'm in the middle of a massiv

Hey man, sorry for the late reply, I'm in the middle of a massive re model and move.

As far as the foundation goes, a structural engineer or concrete contractor should be able to give you a basic answer quickly.

Anything in rods book will work, and it comes down to what works best within your space and budget. My personal experience with RISC-1 clips / hat channel was a positive one. The install is pretty easy from a technical and labour perspective. Carefully marking out the locations is the key. I like that the hat channel, and screws are available pretty much at all building supply houses, so no long waits if you need to grab a couple extra pieces.

The stairs don't necessarily have to be isolated from the studio, they could be adjoined via a simple (typical) door, or left open. I like stairwells for echo chambers, and storage. You essentially put a mic facing the (hard reflective) walls of the stairway, and you can develop a nice natural reverb ala zeppelin, or 80's era NYC (powerstation) sound. After all, those famous verb sounds were the hallways, not the actual drum room. Add a speaker and you can send vocals, guitars, whatever into the stairwell after you've recorded them, and get your natural verb on them.

This doesn't mean it'll be the end all of reverbs, or perfect for everything, but undoubtably worth it. I've used this technique countless times at the studios I work at. Ive personally not used digital reverbs on drums for about 7 years.

Again sorry for the delay in my response, i should be checking in more frequently as my time frees up more.

Cheers man, glad to help, looking forward to watching your project evolve.

Glen, post: 451367, member: 50698 wrote: Ill try to make this sh

,

hey there, in the past 10 years, ive built a two commercial studios, and several home studios, using the info in Rod's book, and even from the man himself once or twice. its pictures and words are priceless. make sure you follow the diagrams exactly, and you'll get the expected results.

as far as your needs, drums range from 100-120db or more depending on style. an everage conversation is about 30-40db, which, is fairly quiet, but loud enough to be annoying if nothing else is going on. a typical wall / ceiling is about blacks about 35db of sound at vocal frequencies (mid range, 1k) the 2nd drywall layer brings it up around 40. green glue 2-3db, and channel 3-6 db depending on what you choose. blocking 40-45db of a typical 100-120db, generated by a drum kit, leaves 60-80db left to hear in the floor above. now keep in mind that's for Vocal frequencies. you lose roughly 6db per octave as your drop from highs to mids to lows, so a wall rated at stc 55, (blocks 55db at 1k) is blocking like 20db down at 100hz.

since your a drummer not a jazz singer, you'll need to consider those low 50-100hz frequencies generated by the kick drum.

keeping it very simple, what your suggesting wont generally be enough for a drum kit, or even really loud singer, to not be distracting. your gonna need those layers between the bays. they're not fun to install, or fast, but it works.

the method your suggesting, is one most suitable for space limted ceilings, which your lucky enough to not have. this saves you a lot of money on Isolation construction materials/methods, and acoustic treatments.

the cheapest way for you to achieve the desired effective to beef up the wall bays with drywall like in the book, then using the 'independently framed ceiling and walls' method/diagrams. this is the cheapest, least complicated way to go. it allows you to hold the most mass, its cheap (framing lumber vs channel), its what carpenters are used to working with, and it takes up only a little more area than the channels. channel is the only way to squeeze 2-3 layers in, meeting the typical 6'8 ceiling requirement in the US.

basically what you end up w is an stc 60 independently framed room, for the cost of one using channel and only achieving stc 45. 10-12db is a perceived double in volume, so your independent room is going to seem "twice as quiet" for the same price, or even less. Green glue is 2x the cost of a standard drywall sheet. so maybe omit the GG and add 2 layers to the bays to keep cost even?

the only channel type system id use for drums, or in my case, a 15,000w home theater, with full size 3 way jbl mains and subs, is the RISC-1 clips / hat channel. I used it the home theater I designed/built because the client had relatively low celing height. we installed 3 layers 5/8 drywall in between the bays, and 3 layers w GG, attached to the clips/ channel. channel and clips both require diligent attention to spacing and installation. its very easy to miss a channel and short circuit the isolation system. mess up the spacing, short cicuit the isolation system. I had to have the carpenters do the clips 2x, and channel 3x, before they got it right. I took pics. its crucial to follow the directions, and triple check.

keep in mind this was the most expensive route, but also the highest performing option with such low ceiling heights. independent framing would have saved about 30% in materials and several days labour, all while being much much more effective, like 20db more effective.

an independent wall and ceiling will have a lower resonant frequency, so it will block more lows.

you also may want to consider using 3/4 osb as your base layer instead of 5/8 drywall. you don't lose much in mass, and it gives you structural rigidity, and some forgiveness for stray screws that miss the stud.

your best bet is to hire someone like rod to make some plans for you and verify things are being done properly. this saves you tons of time and aggravation. re work cost 3x as much. good plans will assure that your time and money will achieve the expected result. the few times I swayed from rods methods, ie had my own bright ideas, I failed. its best to stick w the tried and true.

beyond that some photos and more detailed descriptions are necessary here to start digging into this.