I'm making building plans for a box in box studio.

First of all I want to make the floor float with this:

dead link

or this:

http://www.isover.nl/producten/producten-alfabet/sonefloor_304/

(sorry its in dutch, but as I understand it, all that matters is a good mass-spring ratio and

it's less important what you actually use to make it float)

On top of that I want to make a skeleton with wood, use plywood to strengthen the

floor, use rockwool for absorption and use concrete for mass (both for sound isolation and for

a good mass-spring ratio)

Since concrete is more difficult and more expensive then sand I thought why not use sand. It

has great sound isolation qualities and it's much easier to use.

But after reading the thread above I don't understand the problem with it. If the top layer would be a layer of plywood and then sand for example, what makes it different then using concrete...

Layering the floor would then go like this for example (from bottom to top):

- concrete (already existing in the room I'm using

- sylomer, sonofloor (or neoprene)

- plywood (with wooden skeleton attached to put rockwool in place)

- rockwool

- plywood (with 2nd wooden skeleton attached for sand)

- sand

- end floor like laminate resting on skeleton

In this way you can make the proper mass with sand, still have a MAM layering and

still have a complete detached (floating) floor.

Thanks in advance!

Topic Tags

Comments

thanks for the reply! So as I understand its not a good idea bec

thanks for the reply!

So as I understand its not a good idea because the pressure is different because its more in between the wood instead of only on top of it like a concrete slab?

can't you make the sand more in the same way as a conrete slab, on top of a plywood and with the same mass a concrete slab would have?

is there another alternative to concrete that is easier and cheaper?

What Max is saying to you is that you are risking a structural c

What Max is saying to you is that you are risking a structural compromise. By putting the weight of sand on top of your wooden sub-strait, you are forcing a lot of pounds/pressure down on it, pushing it down into a physical position to where it will wick moisture even faster.

And... by the time you figure in the materials, framing, moisture barriers... and the sand, you're not really saving any money at all, and in fact, are risking damage from a natural source - and that is the moisture.

You could use a pressure treated lumber, but beyond being very expensive, even PT lumber has a finite shelf life. And if you do have to eventually replace joists (which you likely will because they will start to rot), what are you going to do with all that sand?

Going with concrete means that there is far less maintenance/repair involved. As Max said, you simply touch it up with a clear coat sealant every few years. I'd rather do that than have to rip up a floor every 6 years. ;)

BTW... I speak from experience on this. And it's an experience I would never want to repeat.

I do not know where you are getting your information from Yurki,

I do not know where you are getting your information from Yurki, but it is incorrect in two specific and important areas.

You said "but as I understand it, all that matters is a good mass-spring ratio and

it's less important what you actually use to make it float"

It is completely important what you use to develop the spring. If it did not matter it would not be such a big deal would it:) Heck I could set a slab on old tires if I wasn't concerned with decoupling or compression or heaven forbid GRAVITY!

An earth damped concrete slab is one of the best parts of building an isolated environment because it needs no more work, depending on the isolation requirements.

But if you want, for what ever your reasons are, a decoupled floor assembly then you could take owens corning 703 or a similar product and place that on the floor and install 3/4 inch plywood on top of this, two layers.

Space, post: 415481, member: 32398 wrote: An earth damped concre

Space, post: 415481, member: 32398 wrote: An earth damped concrete slab is one of the best parts of building an isolated environment because it needs no more work, depending on the isolation requirements.

DING! DING!! DING!!!

Weeee have a winner!

But if you want, for what ever your reasons are, a decoupled floor assembly then you could take owens corning 703 or a similar product and place that on the floor and install 3/4 inch plywood on top of this, two layers.

There are only two affordable ways to deal with low frequencies... Mass & isolation.

If you are doing one or the other, you damn sure can take advantage of it and do the other. Isolated concrete slabs on compacted sand are THE way to go for room within a room construction.

Put ALL of your low voltage in conduit BELOW the slab, the put ALL of your power overhead and drop it down. You get the maximum electrical isolation for your efforts, minimizing potential RF interference. You get the benefit of not having to worry about it rotting. And properly executed, you can achieve AMAZING isolation between rooms... and until you experience it... you have no idea how loud the world really is.

You should consult with a decent commercial contractor. Following Rod's engineering, it's really nothing out of the ordinary... Residential guys usually don't have a clue and will argue with you and then you end up with not near enough mass or worse... completely screwed up isolation.

thanks for the reply's! @Space yes I get it is important what

thanks for the reply's!

Space

yes I get it is important what you use as a spring, I meant you can use different materials but what is important is that you know the properties and you know the weight of the floor. I'm

in contact with a company (this one: dead link) and they will advice me how much and how to use their product to make the floor float based on the properties of the my studio...I think that is a good way to go...

corning 703 is not buyable in europe/netherlands so it seems, but as I understand it is the same as rockwool?

I plan to make the floor float on sylomer, then use rockwool for absorption between the wooden skeleton (as I do with walls) and then use plywood and the top layer, to take you guy's advice: concrete. Again, the shop will give me advice on the thickness of the concrete and the amount of sylomer....hopefully that will go smooth.

Maybe good to tell, a summary of the rest:

On top of the concrete would go the walls (double drywall and rockwool in between the wooden skeleton) and then the same as the ceiling. Between the concrete floor and the walls I want to do one layer of neoprene for extra decoupling. This covers the inner box, the outer box will have the same walls and ceiling but its directly placed on the existing concrete floor. Between these walls is 10 cm of air.

Sorry to be stubborn, but one last sand question: what if you would put the sand in bags? wouldn't that kill the moisture problem?

You really do like sand, don't you? LOL It's not about the san

You really do like sand, don't you? LOL

It's not about the sand attracting or holding moisture - although I would think that could also be a valid concern depending on what the conditions are where you reside - it was more based on your original question, and as Max mentioned, the issue was the weight that all of that sand would have, the amount of pressure it would exert down upon a wooden structure, forcing it into the ground, which does hold moisture, either directly or through condensation, and over time, forming mildew, mold and eventually, rot. And if your joists rot, then the floor sags or gives way, which can then effect the structural integrity of the walls, which then effects the structural integrity of the ceiling, etc.

Sigh. Alright... fine. You've forced me to confess an incident that I've tried very hard to forget over the years... here goes:

25 years ago, I did precisely what you originally planned on doing. And within 4 years, the joists, subflooring and under-layment had rotted out, to the point where the floor was actually giving way.

Black mold had begun to creep up the walls at the baseboards.

I had to rip up the floor, and then - this is where the real fun happened - I had to get rid of all of that sand. I can assure you that there still remains a blue cloud of obscenities, floating around in my basement, from that long ago blunder, all because I thought it would be cheaper. By the time I ripped up the floor and all the materials, had the room treated for black mold, and replaced 2 walls because the drywall was also rotting at the floor, it ended up costing me easily twice as much (maybe even more) than if I had simply had a pro commercial contractor come in and pour a concrete floor.

Concrete is what you want. Maximum density and isolation, and minimum transmission and maintenance.

You treat it with a clear-coat protectant seal once every couple years, and that's it, that's all. You can forget about it.

It appears as though you have decided to go this way, and it's a smart move.

IMHO of course.

d/

.

yurki, post: 415527, member: 48135 wrote: thanks for the reply's

yurki, post: 415527, member: 48135 wrote: thanks for the reply's!

yes I get it is important what you use as a spring, I meant you can use different materials but what is important is that you know the properties and you know the weight of the floor. I'm

in contact with a company (this one: dead link) and they will advice me how much and how to use their product to make the floor float based on the properties of the my studio...I think that is a good way to go...corning 703 is not buyable in europe/netherlands so it seems, but as I understand it is the same as rockwool?

I plan to make the floor float on sylomer, then use rockwool for absorption between the wooden skeleton (as I do with walls) and then use plywood and the top layer, to take you guy's advice: concrete. Again, the shop will give me advice on the thickness of the concrete and the amount of sylomer....hopefully that will go smooth.Maybe good to tell, a summary of the rest:

On top of the concrete would go the walls (double drywall and rockwool in between the wooden skeleton) and then the same as the ceiling. Between the concrete floor and the walls I want to do one layer of neoprene for extra decoupling. This covers the inner box, the outer box will have the same walls and ceiling but its directly placed on the existing concrete floor. Between these walls is 10 cm of air.Sorry to be stubborn, but one last sand question: what if you would put the sand in bags? wouldn't that kill the moisture problem?

Yurki,

You're not being stubborn... you're being foolish and ignorant to continue with a known failed designed assembly.

The ONLY way that this will work is to put a slab of concrete down, and then place your assembly on top of it... that or put down some 10cm thick sheets of steel... then cover/paint the framing with rubberized coating prior to use of the lumber, and after final flooring assembly. Then, and ONLY then would the wood be protected enough to not rot when in contact with earth... and even then, it's gonna be a marginal improvement, as you will be penetrating the lumber with some sort of fasteners, thus negating the sealant in those penetrated points.

Also, your design concept is seriously flawed in your assumption that you get the advantages of room within a room design and only use one common roof. You are absolutely wrong in this.

Room within a room, is more accurately described as a building within another building... except that there is no interior surface on the exterior building and no exterior on the interior building. Here's the ASCII version of how it's built:

1. Outside space

2. Exterior building surface (brick, stone, siding, etc)

3. Building frame (2x4, 2x6, 2x8, etc.) stud walls - cavities filled with regular fiberglass batt insulation

4. air gap (typical 1" - 2")

5. interior framing (2x4, 2x6, 2x8, etc.) stud walls - cavities filled with regular fiberglass batt insulation

6. Interior room surface (gypsum, wooden sheet goods, etc.)

7. Interior space

The interior space of each room, is then capped off with it's own ceiling, making it a complete room... and virtually it's own building inside of another building.

@DonnyThompson yes, I loved sandboxes as a kid :). hmmm, based

DonnyThompson

yes, I loved sandboxes as a kid :).

hmmm, based on your story and other things you guys say I have the feeling I might not have been clear enough with my situation. And let me also add: Don't worry, in the end I will totally go with whatever will be your advices, sometimes I need to ask more questions so I'm sure I understand things well and learn from this.

MadMax, don't worry about the box-in-box, I think I understand this concept well and what I meant was a double ceiling for both inner and outer box! Both inner and outer room should not have weak spots, so the ceilings are the same as the walls basically (double drywall and rockwool)

I guess I didn't explain well about the following but: there is NO earth/ground with moisture in it in the space where I'll make my box-in-box. I'm gonna make my studio in an existing space of 850 s.f. and 16 feet high (but I will only use 25% of the 850 and go 9 feet high). This existing space is on the first floor and the floor is thick concrete, around 2 feet thick, then some space and then another thinner concrete floor. Also the outer walls of the building are thick concrete and the existing space is dry as can be.

Since I wanna compose and record in the studio I want to have it silent. Below me (not straight below, a bit diagonal) is going to be a bar which make a lot of contact sound from speakers. Good for me: after doing a test with them going for the extremes, it turns out the leakage of sound from the bar is very little (thanks to the thick concrete) and they are also gonna deminish it much and much more coming week's with sound proofing and putting their speakers on rubbers etc (as me, they are not opperational yet and still constructing). Still, the last bit of leakage there's gonna be, I want to get rid of it too. Thats why a good floating floor is important.

What I understood of a floating floor within a box-in-box concept is that: first of all, it can't be a weak spot, it has to have at least the same mass and absorption qualities as the walls and ceilings. Second of all, it needs some mass so it will, with the right 'spring' underneath, create a good mass spring ratio such that the total resonance freq. will be as close to 10hz as possible. To find this ratio, this shop is gonna help me calculate it all trough...

Coming back to concrete/sand.

This is what the floor of the inner box looks like in my build plan now (from bottom to top)

- concrete (already existing in the room I'm using)

- sylomer, sonofloor (or neoprene) to make the inner box float

- plywood

- wooden skeleton with rockwool in between

- plywood

- sand/concrete

- end floor like laminate

(to make the picture complete again: on top of the floating floor the walls,disconnected from the floating floor by a layer of neoprene, and then a ceiling. Then completely disconnected from the inner box the outer box with its own ceiling. walls conncected to the existing concrete floor becaus there's not enough space to make an extra floor for the outer box (i can go to 9 feet high because of a steel framework from the building) and the existing floor is already so massive, I think it will do.

Then the third layer would be the existing big room I guess which of course has his own walls and ceiling....)

so, for the sand/concrete, my original thought was, if you would make sure the mass would be exact the same, they would have the same weight and both have good isolation qualities. I read sand is a good sound isolator also because of its structure.

Anyway, I already accepted the concrete route so if you guy's still say: concrete, np...I'm just trying to understand all this.

I hope it's a bit more clear, I could also finish a sketchup file and send pictures of it....

Now I remember why Rod refuses to reply to threads that lack eno

Now I remember why Rod refuses to reply to threads that lack enough detail.... it's irritating to spend your time responding to threads when you're really just wasting your time.

Yurki, post up some images of your prints please.

There's no sense in playing the "misunderstanding game" anymore than necessary. The fact that I'm not conversant in your native language is a hard enough barrier to overcome as it is. Lets not compound it.

".hopefully that will go smooth." It will not. "This is what th

".hopefully that will go smooth." It will not.

"This is what the floor of the inner box looks like in my build plan now (from bottom to top)

- concrete (already existing in the room I'm using)

- sylomer, sonofloor (or neoprene) to make the inner box float

- plywood

- wooden skeleton with rockwool in between

- plywood

- sand/concrete

- end floor like laminate"

A mass / spring / mass assembly has three things. A hard boundary and an air space(called the spring in a wall assembly be might actually be a spring in a floor assembly) and another hard boundary.

Your information is distorted in that you have a well isolated existing concrete slab and you want to install a poorly suited addition in an attempt to get better isolation, an isolation requirement that you have not made available to us.

A wooden frame supporting concrete is not going to work. Not only will you build a drum head with the bottom sheet of plywood the frame will compress it and the weight of the concrete and the structure you place on it.

Max said we needed details, Rod says the same thing here http://recording.org/index.php?threads/read-this-before-you-post.26684/ and I echo both parties :)

You cannot float a floor without the details of the finished room, it just will not work. You have to know the shape and size of the room and what the HVAC will be, where and what is the weight of every single item that will be placed on this floated floor INCLUDING the structure weight the equipment weight and what the expected amount of people will be at any given time.

Look, I get it, the floated floor is the holy grail of isolation. But until you know your isolation requirements and have a design you can trust and have worked out all the details down to the last nail, you are throwing good money after bad, simple as that.

So do yourself, and us, a favor. Get your plan together and let's build you something that will work based on the facts instead of thinking you are going to outsmart physics.

"...instead of thinking you are going to outsmart physics...."

"...instead of thinking you are going to outsmart physics...."

I've tried it. It doesn't work. Ever.

And, in my own experience, most (meaning "all") of the time, it ends up costing you an astronomically higher amount of money over what you would have paid if you had simply done it the right way to begin with.

It's either right, or it's wrong. There is no half right or half wrong.

Accomplishing either one will ultimately result with a roof coming down on your head, or, with you falling through a shaky structure to your untimely death on the jagged rocks below...

At which point you can hold up your forefinger and thumb and say "I was this close!" as you're wheeled away to the nearest ER. <- exaggerated metaphors for failure. sorry. too much caffeine today.

I doubt anyone would actually die as a result of your studio not being built correctly, unless you decide to kill yourself when you find out that nothing you did (none of which was cheap) actually works. ;)

d/

Man, I must have a bad case of the "thread hijacks" this weekend

Man, I must have a bad case of the "thread hijacks" this weekend... My apologies...

But I really do wish my domain that's hosting the files in my build thread was up and running... There's a lot of clarification in those images that would set you on the right path... but alas, I haven't got time to dig into restoring a complete blog... If any of you are Wordpress guru's, and would be willing to donate some time to dig out the image references, I'll go back and upload em' here to RO.

That being said... Until Yurki can get some drawings up, a few rules of the road to ponder....

1. Mass is your friend... The more the merrier.

2. Isolation is your next best friend... But use it wisely. it is the most expensive path.

3. Wherever air goes, so goes sound.. even through a pin hole... and pin hole's can be QUITE loud.

4. If you make it complicated to build, you'll build it complicated.. and find 3 ways you could have done it easier and simpler and cheaper.

5. The biggest expense you'll have are your mistakes... DON'T MAKE ANY.

6. This WILL cost you at a minimum... THREE (3) times the amount you think it will. Regardless of your budget.

7. The biggest hidden expense in a studio build is your wire... and what is part of your 3x overrun.

8. The second biggest hidden expense is fasteners and caulk.

9. Establish your budget NOW! Know where you're pain threshold is, and where you've gotta stop... if you can stop.

(You've probably never spent this much money in such a small space... Establish NOW how deep down this rabbit hole of insanity you dare fall!!)

10. Be careful what you wish for... You might just get it!

(Just like the dog who latches onto the tire of a moving car, it'll beat your ass up... REAL quick!)

I built my place in just under 2 years... working full-time and building the studio part-time until the last 7 months of the build. It definitely took it's toll on my old ass... but it's worth it only because it was worth doing right. It ain't perfect, but no place is. But it's damn fine for what we do here... It's probably twice what you'll do, but that's only speculation at this point. Either way, if you're serious about building a good room, take your time... review any feedback here with the grain of salt, that you aren't paying dime one for the assistance you'll receive.

However, if "we" as a community see that you're doing something beyond our collective ability... go hire a licensed engineer... which brings up good ol' point number 11.

11. Get your permits and inspections and build to code or better... I hate insurance, but if they require it... GET IT!

(You'll thank me on this one if your country is anything like here... They CAN make you tear it all down and build it WITH inspections.)

12. TAKE PIX!! LOTS OF PIX!!

(You'll want proof of how you lost your friggin' mind.)

Intro I'll do my best to make everything as clear as possible, b

Intro

I'll do my best to make everything as clear as possible, but please take into account: even after spending a lot of time figuring everything out, it's still very new to me and I don't have any building experience. Good thing to know: a friend and my dad are gonna help and they do have building experience. Especially my dad has great experience, owns a painting/renovation company and renovated and builded many many things and houses through his life. Without them I would not have started this project.

But experience in building music studio's they have not, so my task is to do the research and make the building plan. Since I studied electronic composition, I have

some basic knowledge about sound waves and over the last weeks I spent a lot of time in research and talking to two separate people who already build a box-in-box studio. I didn't discusses the concrete floor with my dad in details yet, I wanted to understand first what would be the right way to go sound wise.

Building

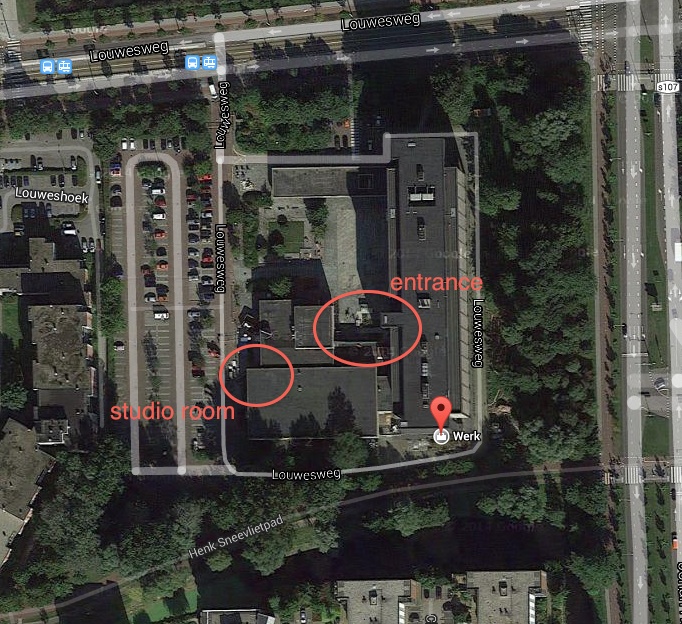

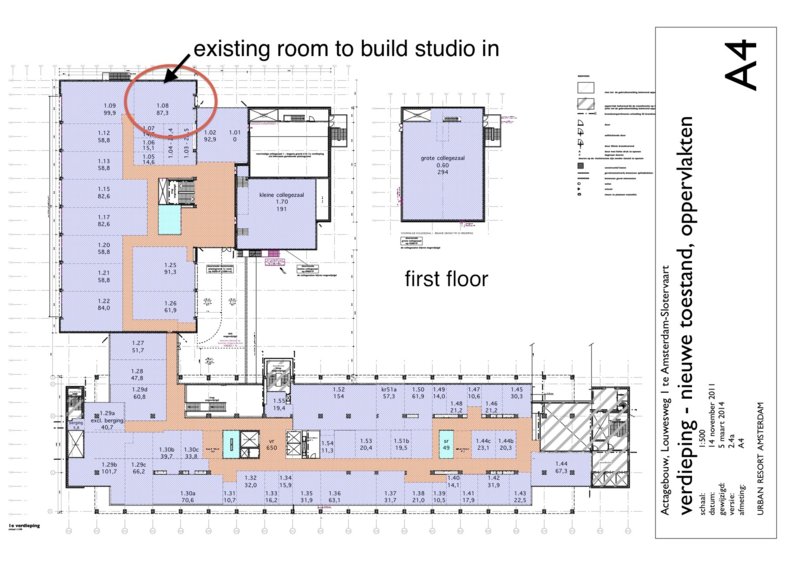

The studio is going to be build in a building full of artists and creative company's (image 1 and 2). It's in the south of Amsterdam where there's not too much noise and the outside walls of the building are thick concrete.

The building is going to be demolished in 2024 (although these things are often delayed...). Building a not too big studio for 10 years is an acceptable investment for me.

Studio Use

For me it's mandatory to make a box-in-box as a electronic music producer/composer here, but I'll use this opportunity to build one that suit my needs too for coming years: some silence to compose and some silence to record. I want to keep it simple: no separate record booth and control room, just one control room with some isolation material placed behind a mic (that kind of solutions). It's basicly mostly me recording piano or other sounds which I'll use in my (electronic)productions/compositions and composing on the computer.

My biggest noisy makers are: an hammond concorde, monitor speakers, subwoofer and a upright piano. I don't plan on making crazy noise (I usually don't wanna put my speakers too loud). I think I worry the most for my neighbors disturbing me actually...

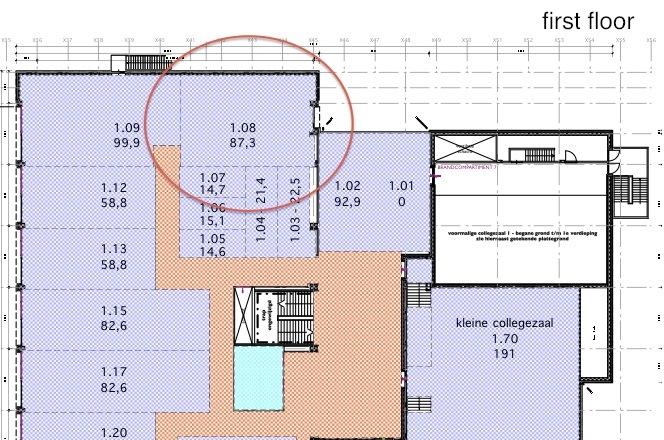

Existing Room (to build my studio in)

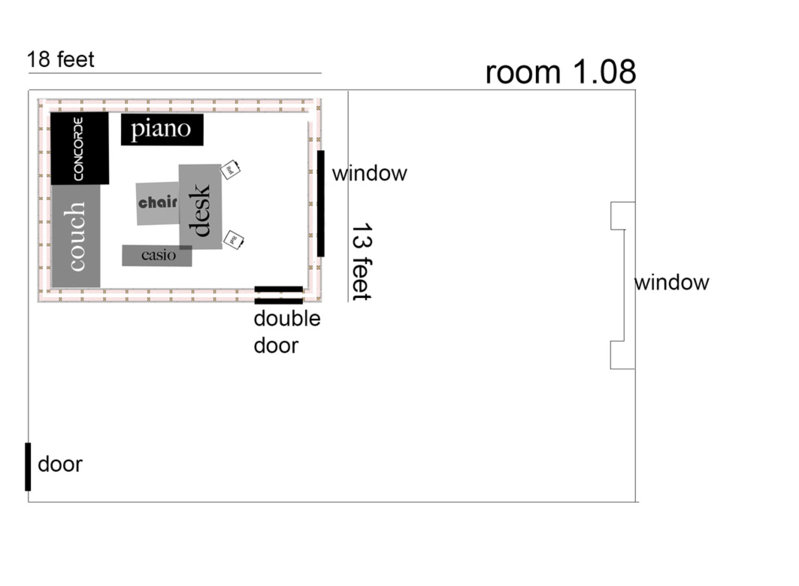

I'm gonna build the studio in an existing, room 1.08 on image 3 and 4. This room is on the first floor and on this part of the building it's the top floor. The dimensions of this room are: 37.4f x 25,4f.

Neighbors

Most of my close neighbors don't make a lot of noise in their profession, my main concern is the club and bar. The club is gonna be build at the most right part of image 4, the white space next to 1.01. In room 1.02 and 1.01 is gonna be less loud music. This club and 'less loud music' next to it are still less of my concern since they will only make a lot of noise during Friday and Saterday night. I of course hope I will be able to work in silence those nights too, but if not, I might have to accept that. My most concern is the bar below me, room 0.43 on image 5, which will make noise more often. As you can see it's not directly below me, but diagonal. I did some tests with these people in the bar (they are both the owner of the future bar and club and they just started renovating the place, it will take some months before both these spaces are ready) and even blowing music at 95 dBa (which they say will be their absolute peak in the bar) only a dim beat was left when we listened in my room (1.08), it was clearly audible, but talking people is clearly louder. I measured 42 dBa during the test, in total silence this room is 30 dB. Still, 53 dB diminishment is not bad at all and they promised me to do more sound proofing (they'll have to...in other places of the building it is clearly too loud right now, so it's gonna be okay)

What they will do is the following: 0.43 is gonna have at the north side double layered glass and an extra wall is gonna be placed, left next to the stairs below the wall is completely replaced by bricks, at the first floor between our and their room (1.08 and 1.02) they are gonna build an extra brick wall and some other sound proofing, the speakers in the bar are gonna be attached with rubbers to avoid contact sound as much as possible (I'm guessing the sound leak from the bar to my room is for the biggest part contact sound). At the entrance of the bar is going to be a terrace. The window on east side of my room 1.08 is going to be replaced by a triple glass (in worst case scenerio, we could put another double/triple glass behind it). The club is going to have some heavy sound proofing on its own, but again, its only friday and saterday...

Studio

To come back to my studio, this studio is going to be placed at the upper left corner in image 6. You can get a better picture of room 1.08, the existing room, with image 7. The studio is going to be in the right corner of the picture. The space looks smaller on the picture then it really is for some reason...You'll even get a better idea with this panorama: http://360.io/gubpKk, zoom out for best result. Again, when you'll have the door on your left hand, it's going to be in the right corner.

Building Plan

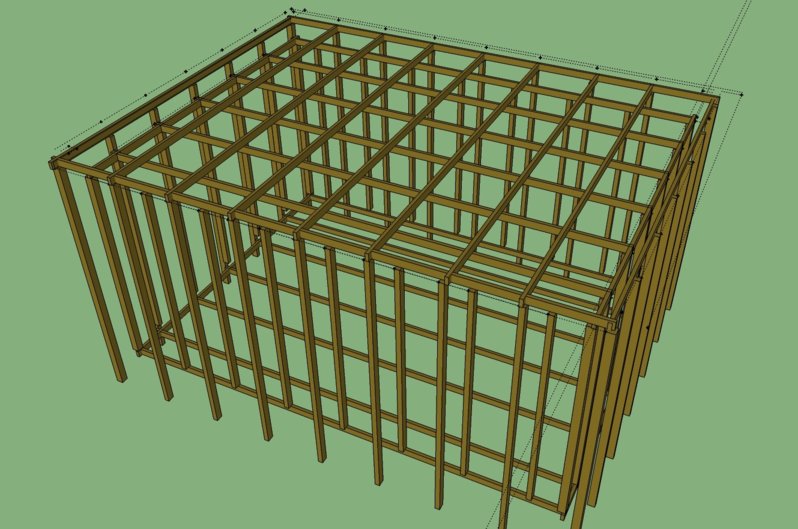

In image 8 you'll find a 3d version of the plan so far. It's only the wooden skeleton you can see here but I'll explain the rest from here. As you can see it contains of 2 walls, one inner and one outer wall. Between the walls is 3.94" of air. Both walls have a separate ceiling, the outer walls is placed on the existing concrete floor (which is guessed to be 2 feet thick concrete, then some air and possibly some isolation, then a final concrete floor of maybe half a feet) and the inner wall is going to be placed on a floating floor. The studio can be as high as 9.5 feet because of the metal construction (see image 7). Right now the dimensions inside are 11,3 f x 16.2 f, the height is not clear because the floating floor is unclear right now.

The corner beams for both inner and outer room are square sized and between them and the other beams of the skeleton is 23.6" space to fit a standard european rockwool layer. Rockwool is going to be 3.15" thick. On the outer side of the outer box is going to be 2 layers of drywall (0.374" per drywall), we'll place them overlapping. On the inner side of the inner box the same thing: 2 layers of drywall. Also on both ceiling again the same thing: rockwool and 2 layers of drywall.

Both the inner and outer wall are going to rest on neoprene for extra decoupling.

Windows and Doors

The windows and doors are not in the 3d plan, for this I trust on the experience of the 2 people who help me. The windows I already own, they are double glazed and 6,5" x 2.13". I'm aware that the window frames should make no bridged connection between the inner and outer box and I'm also aware that I'll have to make the inner window face a bit to the ceiling so I can catch sound waves bouncing on the window with treatment on the ceiling inside the studio.

Both doors are gonna have their own extra isolation and some material to close any gaps and leaks around it.

Floating Floor

The floating floor seems to be the most tricky part. I want it to protect well against contact sound from below mostly (the bar is gonna use speakers that go to 50hz, the club, again, only weekend, is going to 25hz and my own subwoofer will go to 22Hz, but I don't plan to turn it super loud). But it also needs the same amount of mass as the walls, otherwise you'll have a weak spot. Finally: I don't want it to be thicker as necessary because I'm a bit tight in the height with the double ceiling already...

What I understood is that your total studio weight has to be calculated on a square milimeter. Then you need a material that has a spring deflection of 15% for the calculated weight.

Again, I planned to use sonefloor or sylomer, the company who sells sylomer wants to help me with the calculations of the floor.

I understood though, that to get to the needed 10hz resonance frequency of the floor, you need to have a proper amount of mass. Also, I don't think I can use drywalls in the floor, it seems too fragile for it. So that's where I came to the conclusion: a 2 to 4" layer of concrete or sand as the top layer of my floor (the exact amount of mass has to be calculated to get to the 10hz). Underneath it should go some skeleton, rockwool and plywood. If wood is too weak to hold the concrete/sand, I guess I'll have to use a 'dovetailed steel reinforcement sheets'. A metal plate with a shape in it so you can pour concrete/sand in it.

Air

For airing we are going to make an isolated chimney with many corners so sound will have difficulties going in and out. On one end of the chimney there's gonna be a fan which you can turn on and off.

Wiring

I want to keep the wiring simple. All I need basically is 2 separate branch circuits of power for my speakers and the rest. Maybe the simplest way is to put these wire's through the airing labyrinth somehow...

Finalizing

I want to place my piano on extra rubbers of some sort. The same for the subwoofer and Hammond. The speakers have already their poles with some rubber feet and some rubber placement on top.

Of course I will do some proper sound treatment, but that is something I will dive into when the studio is done.

Some Extra Information

- I had many sources for my research but one important one was this article:

http://www.soundonsound.com/sos/feb98/articles/soundproofing.html

Next to that some other articles, youtube video's, a lot of googling and 2 guy's who already build a box-in-box who I spoke with extensively. What surprised me is that they made clearly a few mistakes, but that the end result is very decent and they are both very happy with it.

Some mistakes to name: using screws to connect floor and walls after disconnecting them with rubber (and thus partly destroying your disconnection), not have calculated the mass-spring of the floating floor and not make enough mass there. It is actually on both studio's a weak spot and they didn't use concrete but only plywood.

Nevertheless, I want to do it better then they did. At least I have a much and much simpler room shape and smaller size as they have...

- I learned that both inner and outer spaces being air tight is very important. Even the smallest leak can diminish the effect drastically. We will do everything to make it completely air tight.

Questions

My first questions are: what would be the best way to do the floating floor while still being affordable and not unnecessary thick? Is concrete the only way to make proper mass or is sand or something else possible too?

The second part of my questions would be: do you see any other flaws in my plans or do you have any advice to proceed ?

just in case, an extra link to the same pictures:

https://www.dropbox.com/sh/emovfa2r347dyk9/AADwh2_F--FL43M4cYsWzRjca

Again thanks for all the help guy's, I appreciate it a lot! I'm curious what you think of all this...

- Yurki

"Man, I must have a bad case of the "thread hijacks" this weeken

"Man, I must have a bad case of the "thread hijacks" this weekend... My apologies..."

Yep...the next question to the poster is what is your hard budget and that will be like pinning the tail on the donkey.

I would quit while you are ahead Max. We are teaching from the ground up people that want to start at the top.

I calculated everything through in an excel at 3500,- euro (4776

I calculated everything through in an excel at 3500,- euro (4776 usd) atm. That is including inside treadment. I managed to find shops and places to buy stuff as cheap as possible and since another guy in the building build a box in box for 6000,- euro's and his is twice as big and more complicated (L shaped), I think my budget is doable.

Its what I'm aiming for. If it has to be more, it is as it is. But I try hard to not make it much more.

Suprisingly enough, the rockwool is the most expensive atm. Almost 900,- euro's.

"...even after spending a lot of time figuring everything out, i

"...even after spending a lot of time figuring everything out, it's still very new to me and I don't have any building experience. Good thing to know: a friend and my dad are gonna help and they do have building experience."

This is a red flag for me. This is a very specialized field and form of construction. I think you'd be better off to find someone who is a pro and is experienced at acoustic construction.

@DonnyThompson nah, I don't have money for that and besides, the

DonnyThompson

nah, I don't have money for that and besides, these two guys who build their own box-in-box studio's where on the same level and they managed...

Also, I have two builders with me who are very good.

This choice I made already: I'm fully going for this.

From the article you linked to: "Concrete floors are good news

From the article you linked to:

"Concrete floors are good news from a sound isolation viewpoint because of their mass, but wooden floors can be a real problem. Even if you build a 'floating' floor above the original, the sound leakage will still be worse than that through a solid brick wall. Without major structural work, it's very unlikely that you would be able to use a real drum kit in a wooden-floored room without causing some disturbance to those below. This can be a major problem in commercial premises or flats, especially if there isn't room to accommodate the additional floor height, but in your own house, where some noise leakage may be acceptable, there are strategies that can be used to improve the situation without too much structural upheaval."

As far as your budget... I fear you are about 6-12 times under a realistic budget with you hell bent on this foolish concept of a floating floor... which is only going to make your room worse than if you simply left it alone and built directly on the existing concrete floor.

But, I'm resigning myself from actually participating in this thread much more, as you obviously are in way over your head and will probably do exactly as you please... which WILL result in either someone being killed, or almost as damned stoopid... 3600 EU pissed down the drain for nothing.

Your friend and your dad can have 100 years experience each with residential renovations, but until you get realistic about this and understand that a few weeks worth of google is nothing compared to the knowledge a licensed structural engineer... and that in acoustics, more of the reality is counter intuitive than is intuitive.

Good luck, and I do hope that no one does loose their life due to your stubborn attitude, ignorance and stupidity.

FWIW...This has been a painful thread to read because of my own

FWIW...This has been a painful thread to read because of my own past blunders. Yurki you came to the right place for advice, unfortunately with your mind already made up (even though you didn't seem to know this). For my build I thought, hey I'm a smart guy with years of construction experience and I could do my build if I just read enough forums, books and articles....wrong, wrong, wrong!!!!!The kind of knowledge you need for this kind of work is highly specialized and informed through multiple highly scientific disciplines. There are very few individuals with the correct accumulation of specialties required to make it all work. THEN, each specific situation requires taking that vast knowledge base and applying it to make all the principals involved work, that is if it is even possible. The wonderful and honest folks here are just trying to help. I'm sooooo grateful to the folks that were here when I was in over my head, especially Max and Rod. Ego is a cunning and baffling handicap and there is no room for it when asking for help. You haven't gone too far yet. Go back to step number one and consult an experienced professional with the cotton out of your ears and firmly planted in your mouth!

In my humble opinion of course...peace on you

well, what can I say, it is for me a complete mystery how this

well, what can I say,

it is for me a complete mystery how this thread got out of hand like this,

but I definitely think there is at least some miscommunication going on which

is all too common on the internet. I'm sure this would not have happened if

we would have all stand in a real room.

I haven't made up my mind about anything and I'm completely open for any suggestions. The

reason I reacted on hiring a pro was just because of being afraid it will cost me too much. DonnyThompson

said "I think you'd be better off to find someone who is a pro [....]". The 'I think' was for me an

indication that I would still have a choice to not do it and that's why I thought it would be wise

to explain that I prefer not to, but if you guy's say I really should do that, I'm fine with looking into it.

Maybe the "nah" pushed some buttons, I don't know, anyway: it was not meant bad and I was just

worried about my budget, that's all...

Also, how I explain my plan, it's just how far I got right now,

you can tell everything you want if I do silly stuff (and that was actually the reason I came here), there's literally no ego involved from my side in this project, I really

think you guy's misunderstood my completely there :(.

I also think that maybe you guy's standards are a bit higher then mine...all I want is an affordable space that is workable for me, it doesn't have to be crazy good and it should stay on DIY level.

I also think you have to see it a bit from my perspective: I have this acquaintances that don't have more knowledge and experience on this subject then I have and they managed fine with a similar budget (box-in-box with floating floor). If I can make something similar, I'm very happy, but I'm studying on how I can improve the floor because it's a bit of a weak spot in their design (although they don't have any problems with the results, it works all very well for them). Also, the Sound on Sound link:

[="http://www.soundons…"]http://www.soundons…

i[/]s fully written for DIY (at the beginning: "Technique : DIY") and it's still about floating floors and box-in-box concepts, so that's why I got the idea that you can make a studio

yourself to an acceptable level...

What the SOS article also says is that a concrete floating floor is above DIY level, and that is exactly why I came here,

to look for alternative's, to seek for advice (on DIY level).

(As a side note, I'm not sure if you read my detailed post well...

for example,

MadMax,

I'm not sure why you quote the part about wooden floors. I don't have a wooden floor to start with here as I explained, it's concrete. I also don't use drum kits...

But maybe I don't understand...)

Well, anyway, this thread has for me been very demotivating and in general very unpleasant for me. I'm not sure

where all this strong reactions came from. In general I prefer the more gentle path, but it's okay, happens...

Anyway,

thanks for trying to help at least!

(and I mean that, not ironically....just in case...)

all the best,

Yurki

"Well, anyway, this thread has for me been very demotivating and

"Well, anyway, this thread has for me been very demotivating and in general very unpleasant for me. I'm not sure

where all this strong reactions came from. In general I prefer the more gentle path, but it's okay, happens..."

We believe we are saving you from your yourself.

Personally I would never get involved in what your suggesting fr

Personally I would never get involved in what your suggesting from the point of view of a floating sand filled box....... I fail tp see how you are going to load everything properly - and when it comes to isolated floating assemblies - it is all about proper weight distribution related to all of the various loads in question......

If you want to float then invest the money to float a slab........

But - before you do anything at all - you really should determine your actual needs first....... perhaps the slab it self will provide what you need - and then only impact noise becomes an issue - and that can be dealt with via a simple deck floating over a bed of 703......

That's how it was handled in Studio-H in Manila (Hit Productions' recording studio)

Rod

I feel quite sorry for yurki. His heart's in the right place, bu

I feel quite sorry for yurki. His heart's in the right place, but it does strike me that he, like me, I think, has his own ideas and has some almost set in stone 'needs'. Others reading them see budget directed to what they feel are wasted areas but others find the budget unavailable for what they see as key areas unforgivable. Where I live, if you cannot do a job yourself, then you get in professional, but generic contractors. The price differential to get a specialist builder in is huge. You then have to decide if your own skills in the specialist area are better than the local builders input?

If you build a studio on a budget, then it's not going to be perfect. It is possible to produce a system that puts a numerical effectiveness against features and then it's easier to add or cut features. I'm thinking about things like doors. Proper sealed acoustic door vs timber faced fire doors. Price difference is big, but how about audio performance? How much does an extra layer of wall sheet cost, vs the extra reduction in transmission. Floating floors interest me. Floors that sit directly on the subsoil vs concrete on concrete or sand on concrete. Cost per dB may be totally unrealistic if the reduction is too small compared to another studio feature. For me, my studio acoustic science is not developed that much and my projects always grow on the last one. There's also the question of lifespan. Should we build to commercial standards of construction or keen amateur? If we call in professionals to get the ultimate performance, wow that is expensive. Is it better done by pros? Yep! If the difference is in cost is thousands, the question has to be is it value for money? That's a different one isn't it?

"the question has to be is it value for money?" And how do you

"the question has to be is it value for money?"

And how do you answer that question? You answer it with technical data provided by professional proven results orientated technicians.

I agree with you Paul that the OP wants something that cannot be delivered in the fashion he speaks of. These are the myths that have been available to many for years and they are difficult to overcome when the garbage exists more abundantly than does the the truth and science.

So while it might seem like we here put a complete stop on someones project, it is because most here in my three man circle know that the building design and specifications in want for a specific acoustic result almost always never produce the results that is wanted.

I would not be a friend or be helping someone if I said "sure you can span that 2X6 rafter 14 feet on a 6 on 12 pitch." Because it would not pass code and would put the owner in a potentially dangerous place. Not to mention the sagging that would happen over the months or sooner depending on the loading of the roof due to environmental impact.

The value comes in the form of education in the field and the field can be varied. Construction, sheetrock, electrical, acoustics, HVAC....it all has to come together and it comes together in the same simple way that it would if you were building a house.

You need drawings and drawings are done by people that know.

Space, post: 416843, member: 32398 wrote: "the question has to b

Space, post: 416843, member: 32398 wrote: "the question has to be is it value for money?"

And how do you answer that question? You answer it with technical data provided by professional proven results orientated technicians.

the OP wants something that cannot be delivered in the fashion he speaks of. These are the myths that have been available to many for years and they are difficult to overcome when the garbage exists more abundantly than does the the truth and science.

.

Gawd.. ain't that the truth... and it's a truth I found out the hard way. There's so much guess-work and myth hidden within the "I know what I'm talking about because I built a studio in two days in my garage" blogs out there, that purport themselves to be fact, when in reality, they are based on little-to-no experience, no formula, no measurement, no analysis, and most of the time, written by people who swear that auralex 1" is the answer to all of life's acoustic mysteries.

Much of what the OP wanted to do is not easily reversible. It's one thing to tack up a 2x4 sheet of mattress padding and, once it's discovered that it's virtually worthless, simply pull it down.

It's quite yet another to fill a floor cavity with two tons of sand and then decide after the fact that it wasn't necessarily the best method to implement.

Once again... I'm starting to sound like a skipping record here - READ ROD'S BOOK!!!!

LOL

d/

Room in a Room construction warrants use of concrete as a floori

Room in a Room construction warrants use of concrete as a flooring technique. Don't FILL the floor with sand... Pour the isolated slabs over compacted sand... BELIEVE me... You're quite mistaken about sand being cheaper than concrete.

Look, you can NOT stop any wooden framing for a floor from wicking up moisture. Those floor joists are indeed going to eventually be compromised and with the mass of that sand exerting pressure from the inside... Nope, that ain't anything I wanna deal with. Primarily because once the floor banding gives way from rot, there goes the wall and ceiling integrity directly above the point of collapse.

Independent concrete slabs ended up being the single most expensive part of the build, but when you figure in ALL the extra work, lumber, brackets, braces, vapor barriers, sand, and tool rentals... IIRC, I think concrete was a good 10% cheaper in the long run... All I did was stain and seal the floor. I touch it up with clear coat sealant about every 2 years.