There's this occasional https://soundcloud… tick sound that occurs on playback perhaps every 15 seconds to 1 minute. I tried swapping cables. Tried playing into a different system. This sound is coming from the ADAT XT.

My question is do you think this is a case of dirty heads? Is this one of the symptoms of dirty heads?

Comments

Is it connected to anything else via light pipe? I once experie

Is it connected to anything else via light pipe? I once experienced a snapping noise while transferring music from ADAT XTs to a ProTools rig connected via light pipe - (both running at the same sample-rate). There was conflict over which clock was in charge, and it resulted in a bunch of random snappy square wave spikes written into the PT waveforms. The session had to be re-captured, with a change in which clock was master.

No light pipe. Using the RCA outs. 750 hours or so. Is that cons

No light pipe. Using the RCA outs. 750 hours or so. Is that considered an old man of a machine?

Do the clicks happen at exactly the same place each time you play a particular track?

No. Not on the tapes that I'm pulling material off of. It's random. I can rewind the tape and get past the spots where it makes the tick noise.

unless you are playing back at the wrong sample rate

Isn't sample rate determined automatically by the tape.

Yes. On an ADAT, the format ( you choose, either 44/48) is built

Yes. On an ADAT, the format ( you choose, either 44/48) is built into the sub-code on the tape when you format the tape for use.

The reason I asked about the number of hours on the deck, is that you may need to have the R-DAT head repaired - or even replaced. They don't last forever. Like any tape head, be it analog or digital, there is still frictional contact between the tape and the tape head; it doesn't matter if it's a stationary head like on an analog deck, or a rotating head like that on an ADAT, DAT or Tascam DA88.

Tascam's DA 88 had a definitive, finite life on the heads, before they needed to be rebuilt/re-lapped. Tascam made a lot of money on that deck, because the rotating head in that machine ( including the DA38, 48 and 78) was only good for around 600-650 hours of record/play time (or so). And when the head started to go bad, you would hear little clicks and pops intermittently. The noises grew worse as the head continued to wear down, and once it hit that mark of around 650 hrs or so, it wore down fast...

There are a few things you can do with your ADAT that may solve the problem.

The first is to try a "Reset to Factory Default":

Hold down the record and play buttons simultaneously while the power is off

While continuing to hold these two buttons down, turn the power back on

The display should read "INIT". (The same goes for all ADAT model machines).

If you are using a BRC with the deck, try a full BRC diagnostics check,

(this will enable you to see if all the lights, the display, buttons and internal software is all working correctly on the BRC, and that communication between the remote and the deck is solid and not introducing potential interrupts):

Turn off the BRC

Hold down track buttons "1" and "8" together while turning on the power to the BRC

The BRC will then go into a "Test" mode, and it will cycle through all the display lights and buttons

The display will cycle through and test a number of different functions, including its internal software

It will then ask you to press any button to test all the buttons and contacts to see if they are all working

It will display (on the display) what button you just pressed, this way you can test to see if the BRC remote is fully functional.

To find out how many hours are on the R-Dat Head:

Hold down the "set locate" and the "stop" buttons at the same time

You should see the hour meter on the front display the number of head hours.

For example, if it reads 0119 then it means you have 119 hours on the rotary head,

This does not indicate the total time your ADAT machine has been turned on. It only shows the number of hours that the head has been in contact with SVHS tapes in Play and Record modes.

Something important that you should know: You need to remember that when running a cleaning cartridge on the deck,, you can actually log triple the time while using a cleaning cartridge on the head as compared to the "real time" number of hours that are counted during "standard" use with regular recording tape.

If none of the above solves your problem, I guess at that point I would suggest that it may be time to look into having it serviced. Be careful here, though. You just might end up paying more for servicing than you would to just buy another machine off Ebay with lower hours.

I don't know where to tell you to go for servicing, though. I guess I'd start with Alesis and see if they still do that type of maintenance, or if there may be an authorized service center somewhere that you could send it to.

Just a a few suggestions. ;)

d.

I just read something bout ADAT's that I wasn't aware of ...alth

I just read something bout ADAT's that I wasn't aware of ...although I can't attest to the accuracy. I'm just forwarding what I read:

"According to ADAT Service Technicians, the ADAT heads never really wear out. The SVHS tape rides on a cushion of air on the rotary heads - an air bubble is formed because of the spinning rotary heads and the tape movement causing air lift, so it really does not come in contact with the heads. The SVHS tape does come very close to the heads, but only close enough so that the heads can read the digital information recorded magnetically on the tape..."

According to the source, 3000+ hours of time on the rotary head - without any problems - isn't uncommon.

I didn't know this. I wonder if it's true.

Ha! Then when we had three, why did the manufacturer repeatedly

Ha! Then when we had three, why did the manufacturer repeatedly charge us for new heads. Actually, JVC said very similar things, but concluded that tape tension as the end of spool was reached overcame the air float effect, as did the take up tension right at the start. The large spool short 30 minute tapes were kinder. However, the constant back and forth shuttling on ADATs wore the heads pretty badly - hence why we went through heads quite quickly.

DonnyThompson, post: 424421, member: 46114 wrote: "According to

DonnyThompson, post: 424421, member: 46114 wrote: "According to ADAT Service Technicians, the ADAT heads never really wear out. The SVHS tape rides on a cushion of air on the rotary heads - an air bubble is formed because of the spinning rotary heads and the tape movement causing air lift, so it really does not come in contact with the heads. The SVHS tape does come very close to the heads, but only close enough so that the heads can read the digital information recorded magnetically on the tape..."

According to the source, 3000+ hours of time on the rotary head - without any problems - isn't uncommon.

Hmm, how do you guarantee contaminant-free tape so that it always floats on the heads? In my experience, it's usually scratch damage that triggers a replacement rotary head rather than the sort of more even wear that you see on the fixed heads of reel-to-reel machines.

DonnyThompson, post: 424421, member: 46114 wrote: "According to

DonnyThompson, post: 424421, member: 46114 wrote: "According to ADAT Service Technicians, the ADAT heads never really wear out. The SVHS tape rides on a cushion of air on the rotary heads - an air bubble is formed because of the spinning rotary heads and the tape movement causing air lift, so it really does not come in contact with the heads. The SVHS tape does come very close to the heads, but only close enough so that the heads can read the digital information recorded magnetically on the tape..."

According to the source, 3000+ hours of time on the rotary head - without any problems - isn't uncommon.

not true about the "cushion of air". old wives tale. it is true ADATs will run more than 3000 hrs. i just sold 3 machines all with more than 3000 hrs. on them. i still have 2 more machines with near that i am saving to archive ADAT tapes i still have.

I still have several of them here (actually the Panasonic MDA1 w

I still have several of them here (actually the Panasonic MDA1 with XLR connectors instead of the Elco multi-pin) collecting dust - with less than 1000 hours on them. I bought two of them new, and the only real issue I ever had was replacing the idler tires. The slave units have to do a lot of shuttling back and forth to sync up with the master, so they really chew up the idler from all the rapid-fire stopping and starting, forward and backward.

I was never one to reuse the same tapes over and over again either. Everything just got archived, along with a set of safety copies. I think always using fresh tape helps keep excessive amounts of the magnetic coating from wearing off the tape - keeping the heads cleaner.

I always felt the cleaning cartridge was probably the most abrasive / destructive thing you could run through them, taking years off their life.

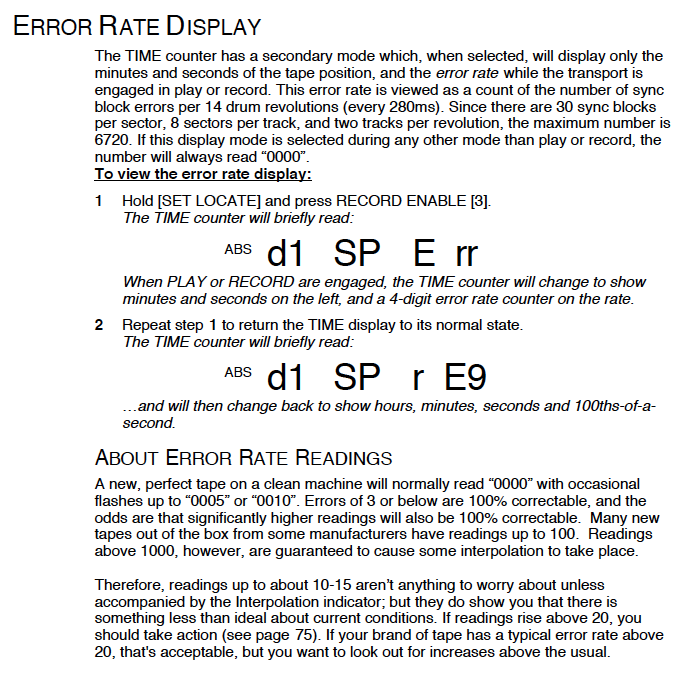

I don't remember the keystroke combination like Donny's post, but isn't there a way to monitor "Error Rate"? I'd be curious to see if there's a correlation between tape errors and the Dr.'s 'tick sound'.

It can't hurt IF, and only IF you know how to take the case off,

It can't hurt IF, and only IF you know how to take the case off, get out the isopropyl and do it gently, effectively and safely. Whenever I am forced to use a cleaning tape, I always remember the VERY fine line between being abrasive enough to remove the surface dirt, and none of the head itself. Whenever you clean a rotary head machine of any kind, most of the crud builds up in the gap between drum and head, and often it's this that lifts the tape off a perfectly good head. I'm old enough to remember VT machines, on their racks with the lids permanently off, on runners - so you could slide them out, squirt and dry before each live session.

paulears, post: 424451, member: 47782 wrote: It can't hurt IF, a

paulears, post: 424451, member: 47782 wrote: It can't hurt IF, and only IF you know how to take the case off, get out the isopropyl and do it gently, effectively and safely. Whenever I am forced to use a cleaning tape, I always remember the VERY fine line between being abrasive enough to remove the surface dirt, and none of the head itself. Whenever you clean a rotary head machine of any kind, most of the crud builds up in the gap between drum and head, and often it's this that lifts the tape off a perfectly good head. I'm old enough to remember VT machines, on their racks with the lids permanently off, on runners - so you could slide them out, squirt and dry before each live session.

i never had much success with cleaning tapes. i had 5 adats in a rack on sliding shelves as Paul mentioned. i took out all the screws on the lids except for the one in the middle of the panel for quick access. i ordered idler tires by the dozens from a company called MCM and i became very adept in cleaning and tire replacement. those old adats sounded pretty decent but they were a pain to keep running in sync. i particularly dreaded sessions where i knew the clients would want to do a lot of punches and shuttelling between search points.

You're right Kurt, it's easy to forget that wasn't all that long

You're right Kurt, it's easy to forget that wasn't all that long ago. Kids, before the DAW you'd have a guitar player want to take 150 runs at a 2 measure guitar solo (that he SHOULD have worked out BEFORE the Record light went on). All you could do was cringe watching the slaved deck(s) trying to play catch-up, while he would say, "let's do that part again, I can do that better".

[[url=http://[/URL]="http://www.mcmelect…"]MCM[/]="http://www.mcmelect…"]MCM[/] was, and is, a good source for things like quality cleaning chemicals and foam swabs too, (which unlike regular cotton swabs, don't have loose fibers to get snarled up in the rotary head). I've been dealing with MCM regularly since '83, they've evolved their product line with the times, but are still a standout at what they do. Still one of the few places you might look for belts, idler tires, n'such.

[I just found a new (15+ yr. old) ADAT idler tire in my desk drawer]

unless you are playing back at the wrong sample rate, it's proba

unless you are playing back at the wrong sample rate, it's probably dirty heads. [[url=http://[/URL]="http://www.google.c…"]cleaning adats[/]="http://www.google.c…"]cleaning adats[/] ...