dvdhawk - I'm starting a new thread with details on the proposed ICF building project. Here's the background information our moderators like.

Location: Western PA -USA

If you looked at a satellite photo of my location you would see all the forests and farmland, and you might think that outside -> inside noise wouldn’t be much of a problem in such a rural setting. Not true. We just have different problems than the suburbs and cities. We’re in the middle of a small cluster of homes along one of PA’s primary 2-lane roadways and we’re just 1/2 mile from Interstate-80. We’ve got great neighbors and we all try to be respectful and not make too much racket, early or late. I personally don’t need much volume to be happy and I’m much more likely to pick up an acoustic guitar or play an unplugged electric. But due to some unresolved karmic debt from a past life, my son plays drums. Thankfully he’s not a basher, but still, a 16 yr. old drummer playing the kind of music 16 yr. olds and his friends would play. (on the loud side) I own no less than 3 decibel meters, and have never measured the dBs inside or out when he's playing. I’d have to guess 95-100 dB inside would be the maximum inside level.

Project Description:

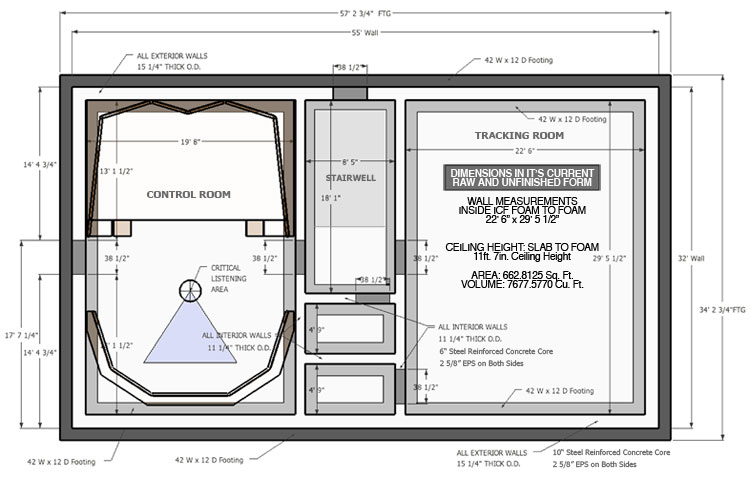

Multi-Function 55’ x 32’ Multi-Level Building attached to existing home.

Goals of the entire building project:

To make the most sound-proof and energy-efficient building possible on a reasonable budget.

2-car Garage with Workspace and Storage.

Recording and Production Space for my solo projects, band projects, and my 16-yr. old son’s band(s)

Production Space for occasional outside recording projects, and A/V post-production.

Control Room that can double as client-friendly Video Screening Room

Rehearsal Space for me and my son’s bands ( they practice a lot more than us old guys )

Workspace, Office Space, & Storage for the A/V Contractor business.

Project Status: Making final decisions about design, construction scheduled to begin with footer work in the spring, basement walls immediately after, - March if we’re lucky. It’s not too late to make changes!

Known Construction Challenges:

Attaching to existing house at correct heights.

Sloping lot - 30ft. drop over 300ft. length of lot. < somewhat improved >

Excessive ground-water needs adequate drainage. < improvements made and more plans in-place >

Driveway needs reworked. < major improvements made >

The patience of my wife of 25 years, who does not like change.

Noise Issues: Typical neighborhood noises - not complaining, just listing all the things that could wreck a recording.

Road noise - cars, trucks, Harleys, punks with car stereos I can literally hear coming a half mile+ away.

Moderate truck traffic with potential for much more if they make I-80 a toll road through PA. (which state lawmakers are trying to do)

The big trucks are a problem here. They're either coasting and Jake-Braking down one grade, or going like hell to get up the other side.

Neighbor’s idling big rig - sometimes rumbles for hours at a time, especially in cold weather.

Snow plows - an earthshaking rumble as they scrape the ice and snow off the roads in the winter.

Barking bird dog(s) in their pen - sometimes hours on end - year round.

Hunting related gunfire - sporadic and seasonal.

Lawn mowers - Neighborhood lawn mower brigade runs for hours - spring through fall.

Motorcycles (on and off-road) - loads of Harley traffic and the occasional ATV or dirtbike on the property behind us.

Helicopters - the good folks at Stat MediVac fly over regularly, between 2 local hospitals and interstate accidents.

Jets - that’s right... Jets. A couple times a month - F18s, A10s, C130s, etc. ripping through here full-throttle at tree top level. We apparently live at a navigation point for training flights and they hit a spot 1/4 mile East of here and bank hard North just outside my window. That leaves us in the loud wash, but it doesn’t happen enough to be a huge problem. And heaven help me, I love watching them go by, when I can look fast enough.

Vocation: I run my business out of our medium-size 2-story farmhouse style home.

Sound/Video Contractor - specializing in churches & schools. (95% of my business)

Professional Sound System Installation ( mixers, power amps, speakers, mics, racks, the works )

Video Projection Systems - ( screens, projectors, presentation software )

Theatrical Lighting - conventional lighting consoles & dimmers, plus new LED technologies

A/V production - Pro Tools & FinalCut Pro (5% of my business)

Special Interest / Corporate Video Production

Radio Commercial Production

Remote Recording - Live Concerts etc.

Recreation:

Still making music 2-3 times a month in a 3-pc rock / blues band

Golfing, fishing, motorcycling ( not enough free time do to any of these lately )

Research:

I have several great books including Rod's, and I've been doing my homework, reading everything on the Auralex & GreenGlue sites, at John Sayers' forum, and recently joined up here at recording.org to name a few resources.

Drawings and Pics to follow because, 'That’s all I need in life, a little place for my stuff.' - George Carlin

Comments

We had really nice weather again today, so they were hustlin' wh

We had really nice weather again today, so they were hustlin' while the hustlin's good. Bad weather is on the way.

That's 9ft. shown there. There's one more course of forms tomorrow which gets it to 10' 6" (which is the target for this floor). I lost count of how much horizontal rebar there is in that span above the garage doors - A LOT. Tomorrow it's time for vertical rebar etc. before the big snowstorm we're expecting in the afternoon.

Tomorrow's course will put us 24ft. above the footings. Now we're gettin' somewhere!

Monday we'll mount the hangers and anchors that will support the floor joists for the floor above the garage.

We'll triple-check that we have all the utility sleeves in place that we'll need, and hopefully be pouring concrete bright and early Tuesday.

WOOOOO HOOOO!!! It's going up every bit as fast as I thought it

WOOOOO HOOOO!!!

It's going up every bit as fast as I thought it would.

I'm gettin' excited for ya!

Have you been able get any time to just get in the enclosure to listen and get a sense of what the structure sounds like? Not that it's all that significant, but experience has taught me a very subtle lesson...

The more time you can spend in the building and each room, the more "in tune" you become with each space. It's almost zen like how you can almost feel the personality of the space come together. I guess it's (similar to) what native American Indians describe as communing with the space.

Maybe it's because I've done so much of my own work here, but having that "bond" over time, I really think it gives you an advantage over some of these studios where the owner has contracted 100% of the structure's build.

Good luck with the weather and getting the next pour done on schedule!

MadMax, post: 299191 wrote: It's going up every bit as fast as I

MadMax, post: 299191 wrote: It's going up every bit as fast as I thought it would.

Have you been able get any time to just get in the enclosure to listen and get a sense of what the structure sounds like? Not that it's all that significant, but experience has taught me a very subtle lesson...

The more time you can spend in the building and each room, the more "in tune" you become with each space. It's almost zen like how you can almost feel the personality of the space come together. I guess it's (similar to) what native American Indians describe as communing with the space.

Maybe it's because I've done so much of my own work here, but having that "bond" over time, I really think it gives you an advantage over some of these studios where the owner has contracted 100% of the structure's build.

The shell is going up quickly, no doubt - but we've only just begun.

It's an interesting way to build. Unlike conventional stick-built, where they tack together a frame and connect the dots, this literally goes from the ground up. And although I haven't been 100% a spectator, for the most part I've been staying out of the way of the professionals, when it comes to the construction of the shell. Business is booming and I'm fortunate to have loads of my own work to do, so I've been working stoooopid long hours at the job I know how to do, so I can pay these guys to do what they know how to do. I've got a general contractor who will take care of setting the roof trusses and the roofing and he'll be handling the structurally critical interior work. [floor joists etc. for 2nd floor, stairs, exterior doors, plumbing essentials.]

My job will begin after the place is buttoned up and we get down to the room within a room part of the project. Once we're under-roof and have the necessary doors in place, I'll start with some analysis. The wiring will be all me and at this point it looks like the majority of the interior construction will be all me - or at least me and the occasional GC. I'll never have your woodworking capabilities, so I'll just have to deal with that, and there are some things I'll just have to pay someone else to do.

One important thing I've learned from your epic is this; people are eager to offer help, but hard-pressed to show up and get their hands dirty when it gets right down to it. You couldn't even coax some of your friends over with cash. One of the most impressive things about your project has got to be the fact that you did the vast majority of it literally, all by yourself - which is flat out amazing. Thank goodness for your buddy GCubed and Nic the intern, or you might still be swinging a hammer rather than tracking. I've already got an intern - my teenage son, with a strong 17yr old back, a love of music, and an interest in architechture. Plus, he's already on my insurance! He plays drums in 2 different bands, so he's motivated and as anxious as I am to see this thing finished.

As far as what the enclosure sounds like.... pretty much exactly what you would expect an empty bunker to sound like. Remember a few months back, when you were contemplating building a reverb tank (cuz you really needed more to do) ?.....

In their raw form (all concrete and EPS) my control room & tracking room 'spaces' both have a very pleasant, very dense (but not dark) reverb. I'd guess we're currently somewhere around 2 seconds, give or take. I'll take the handheld RT60 analyzer down there this week and see if I can get an RT reading. The scaffolding they used for cribbing the garage floor is still in there, but ready to come out. It will be a truer test without that bit of structure in there, so I've kinda been holding off. A month or three from now, we'll have to determine how much of that liveliness we want to keep in the tracking room.

Which - for those who have skimmed down to here - raises the question:

Is there a rule-of-thumb RT you shoot for in the tracking room? (assuming that the density and tone of the reverb are good)

Max, thanks as always for your input - you are my hero!

Back to going over the wiring & plumbing, to make sure we don't forget anything between now and Tuesday. A session with a hammer-drill seems almost inevitable - I'm trying to avoid a mistake that will involve diamond tipped sawblades or jackhammers. :biggrin:

mrmelody, post: 299201 wrote: Those some tall forms you got ther

mrmelody, post: 299201 wrote: Those some tall forms you got there!

Look good!

Big snow storm comin' , get them covered!

24ft. down, [up] 9 more ft. of wall height to go. The crew only put in about 3 hrs this morning. They got their last course in place, got them covered up, and were gone by noonish. We've battened down the hatches and are waiting on the snow.

Hawkman, Yer' too kind bro... way too kind (if you were to conv

Hawkman,

Yer' too kind bro... way too kind (if you were to converse w/TheBoss© anyway.)

Ooof.. RT60 in the tracking room... That's pretty subjective and wide open. But since you opened the door... :smile:

Classic concert halls are between 2.5 and 3.0 seconds... obviously, in a smaller enclosure, non-concert hall setting, that long of a verb would probably sound less diffuse in likelihood, and probably be way too strong of a tail to deal with.

I honestly think that achieving some derivative RT60 of 2.5 seconds would be pretty good to go for. That way, if you need to get to a standard (in live sound) 2.5 second verb, it would sound more or less natural (e.g 1.25, .625 or even .3125) to add a digital verb, or even a plate or chamber. (hint/hint)

I'm still exploring the RT60 of my tracking room, but so far, I'm finding that I can easily get towards 250mS with a mic placed about mid-way in the room, with the source against a wall. (Hopefully I'll get permission from the guys I'm tracking - Hot Politics - to put some samples up.) I'm thinking that I should get somewhere between 300 and 400 mS as a maximum.

One of the most amazing things I'm finding, and can't urge you, or anyone else, enough to do is to make the tracking room as asymmetrical as possible... ESPECIALLY including the ceiling. It makes such a HUGE impact on the way you can track instruments, it's kinda' scary.

I mean, I tracked the very first song in the room in the "wrong end" of the room, and mic'd the OH drums with side address mic's in an XY. The sound should have been totally shite, but is so lively and slappy, it's cool. Moving the kit around to one side corner, and now back in the position that is the optimal position... I've got 3 distinct sounding rooms, with 3 different RT60's.

The other thing that I've found is that having tiled the bathroom, I have my chamber! If I open the doors to the tracking room, all the way to the bathroom, (shutting the CR door, obviously) I can get a full 2.5 second RT60 w/delay... from the tracking room to the center of the bathroom. I do love natural sounding verbs so much more than anything digital that mimic's a natural reverb.

David, I want you to know that you've got an open invite to skoot down here any time to check the room out. You're building from the ground up, and seriously... I think you could scarf up a lot of good info from a day or so down here.

No matter which way you go with your RT60, I wouldn't go too short (<125mS) nor too long (>1.25s). I guess you might call it a Goldielocks RT... somewhere in the middle, (towards the shorter end) would be just right.

it's so subjective, but it really matters. RT60 for Max's track

it's so subjective, but it really matters. RT60 for Max's tracking room is about .25 - .40, and it does have a medium size (but good) sound to it. In fact it sounds exactly like the room it is, not an echo chamber. You sure don't want 2.5 seconds of reverb in such a room as yours dvdhawk. But how large can it sound, maintaining a diffuse sound field and not drowning the direct sound? Well, I could tell you, or you could do some reading and find out what you need to know. My advice is to make the room sound large and open, use gobos and things to cut reverb when needed.

Thanks for your feedback guys. It is very subjective indeed.

Thanks for your feedback guys.

It is very subjective indeed.

I've recorded in studios with all the reverberant charm of a small gymnasium and others with 7ft ceilings and 100% soft surfaces. One felt like you were playing in a nice shiny warehouse, the other like you were in Punxsutawney Phil's shag carpeted groundhog hole. And for obvious reasons, I didn't care for either end of the spectrum. The worst part is, the 'small gym' studio was allegedly a "million-dollar" room in a professionally designed facility around late '80's - early '90's.

Much of what's out there to read has conflicting information, depending on the particular taste/age/bias of the author. I suppose some of the resources are getting a bit dated and ideology has changed over the years. Control Room design has certainly evolved over the decades. There was a time it seemed like everybody wanted everything as dead as possible. So I was wondering if there was a conventional wisdom for tracking rooms circa 2010.

I expect to be doing a lot more rock and blues than anything else, and I tend to favor a more 'live' sound. So I will take my time when the time comes and make an effort to not over-treat the room. I know the room will change drastically after we trap the corners and drop in a proper ceiling. Those two things are non-negotiable, but the shapes and angles of any dividing walls, and amount of absorption/diffusion are still very much up for discussion.

For the last 18 years I've had to record everything on-location, so I'm a big fan of gobos. I generally like what I hear coming out of studios that use the big room / gobos / oriental rug approach. To me it seems like the best of both worlds, if you have the time/patience to find the right balance for the given instrumentation. We've managed some really decent recordings under some pretty bad circumstances - so just having a control room will be a luxury we've never had before. Getting to fine-tune the tracking room will be beyond a luxury. But that's a ways off yet, and there are a couple thousand other decisions to make before we get there. I'm just trying to plan ahead.

Meanwhile, I've been reading everything I can get my hands on for years. I ordered yet another relatively current book on the subject last week that I'm anxious to read.

Right now the inside dimensions are 29' 5 1/2" L x 22' 6" W x 1

Right now the inside dimensions are 29' 5 1/2" L x 22' 6" W x 11' 7" H

My thoughts are to focus on getting the exterior shell finished, including the exterior doors. Then concentrate on the two soundproof doors on either side of the stairwell/airlock. I feel like once I've got that done, I can take some meaningful readings. I want to make sure my doors and ducts are as quiet as possible before I commit to the final design. Do you think this is a logical approach, or am I kidding myself?

The Control Room will definitely be room-within-a-room, something along the lines of what's shown in the drawing (some angles may vary). I also want to see how much bleed there is between the Control Room and Tracking Room before I add more leafs to the Tracking Room. This building is kinda monolithic, so if there's a bunch of structure-born vibrations room to room I'll have to make the Tracking Room room-within-a-room too. One thing is for sure, the EPS can't be the final finish, so one layer of drywall minimum on any given wall. We'll put in a stud-wall in the Tracking Room if necessary and add Green Glue and additional layer(s) as needed.

Standard practice - non-parallel walls, asymmetrical shapes, bass traps, will all be used, so there will be some framing involved whether it's a full-blown room-within-a-room or not. Andre and Max have both suggested an iso-booth of unspecified size/shape inside this room and I'm all for that. I'd also like to make several large corner cabinets to use for storage, if it's possible. If I can build a corner cabinet that can work as a bass trap, without adding any of its own weird boxy resonance it seems like a win-win. I'm going to need a little studio storage somewhere for mics, headphones, cables, etc.

The ceiling, which is currently 11' 7", will be lowered to some extent using a suspended ceiling and a decent quality acoustical 2x2 tile. I'm still trying to net a ceiling height of 11ft. over parts of it if I can. I'm looking into ways I can add some slopes / contours / angles to the ceiling.

I would welcome suggestions on how make the best use of that space if you've got any ideas.

Thanks all, I appreciate your interest and input!!

"I'm looking into ways I can add some slopes / contours / angles

"I'm looking into ways I can add some slopes / contours / angles to the ceiling."

Simple enough with a drop ceiling. Map it out and the hangers bend wire according to the elevation you want at specific places.

Since there is no mass in a drop tile it isn't going to contour the full spectrum. If instead you have a room-in-room with a substantially massed ceiling, this can be contoured to add the diffusion you may be looking for.

my 2 cents, the ceiling must absorb as much bass as possible. it

my 2 cents, the ceiling must absorb as much bass as possible. it should also provide diffusion and a fair amount of absorption so the instruments do not bleed when not desired. its especially important the least amount of bass possible bleeds into other mics, and this is most important on the ceiling, as its the smallest dimension and the resonance is higher, making filtering during mixing less effective.

the iso booth inside the tracking room, could very well be put in the bottom right corner. along with that storage cabinents can go in the opposite corner. then they can be angled to provide some specular scattering for the room as a whole. and, for the cost of a few inches, the volume behind them can double as basstraps by putting mineral wool on the wall and a slight air gap between each structure. this will improve the resonances by widening their Q instead of acting as an unpredictable diffusor, much as splayed walls do.

of course thats down to preference as well. you could also find a service with access to computer room simulators which CAN map the nodes and antinodes for non-parallel rooms. its all calculated really.

Today's concrete pour was postponed - bummer. The snowfall we'v

Today's concrete pour was postponed - bummer. The snowfall we've been getting has thrown everybody's plans behind a day or two.

Thanks for your insight gentlemen.

A much needed kick in the ass to stay focused on the big picture and not get tunnel vision worrying about isolation or any other one thing. I'll need a new mantra - the accuracy of the sound of the recording space will go a lot farther in making good sounding recordings than the amount of isolation between tracking and control rooms. And in this case, it seems that trying to attenuate more of the bass before it gets out of the tracking room will help both causes.

If I've still got any shekels at all left when the time comes, I may have to see if I can afford a professional consultation.

Thanks again.

Something I've been told, and have seen posted from MANY of the

Something I've been told, and have seen posted from MANY of the most respected tracking engineers in the industry is that the difference between a good tracking room and a GREAT tracking room is that a good tracking room is even across the audio spectrum. A great tracking room is one that has some character.

Look at all the acclaimed rooms... Motown, Avatar, Ocean Way, Electric Lady...(just to name a few) Some aspect of these rooms has a unique quirk in them that just works great for something. True, a lot of what makes those rooms so special are the people in them, but the rooms themselves have a characteristic that a good engineer can exploit to his/her advantage.

Maybe you DON'T want to trap one corner too much, so the bass or the kick are good and punchy. Maybe you want a wall that's pretty reflective so that guitars and vox are bright and sparkly.

I'm not saying this is what you should do. I'm just sayin' that these are things that I'd think about as you go forward.

I'm going to ask for some leeway here, but I think you would indeed do well to get a consult with Rod. The way my room turned out, I can tell you that I'm amazed at the versatility that the room actually has... and I'm just now really getting a chance to explore it!

The only thing I will say that you should do, is to be open to ideas and explore whatever you think is even the goofiest of ideas for the tracking environment... who knows... you'll likely hit on some idea that could make it the next "Motown"!

A great tracking room is one that has some character. but the

A great tracking room is one that has some character.

but the rooms themselves have a characteristic that a good engineer can exploit to his/her advantage.

be open to ideas and explore whatever you think is even the goofiest of ideas for the tracking environment...

I think Max is right on with this.

Stay open to all of it Hawk.

I'm a newbie studio builder, mediocre engineer, and recording artist and I have to say with my experiences through the years, I have found the same things Max has mentioned in a all situations. As an engineer and especially as an artist.

What a fun trip!

get the snow blowers out and get those guys back to work! ;)

The joists for the 2nd floor above the garage will be delivered

The joists for the 2nd floor above the garage will be delivered tomorrow morning.

The pour for the garage walls was pushed back to Friday - believe me Mr. M these guys aren't the least bit afraid of working in the cold & snow. When they're here 2 of the 3 trucks have plows on them plus a skid-steer. I've barely had to lift a shovel so far this winter. Anyway, the concrete pump truck had another project ahead of us in the queue. Even though they knew there would be no cement work, my concrete guys still showed up and took the cribbing out of the basement and made an early day of it.

On the other stuff - I'm definitely wide open to suggestions. I've been kicking ideas around, but always had that space as 'to be determined'. I've got a pretty good idea of where I want to go with the control room. Symmetry I can comprehend. But there are so many variables in the tracking room it's staggering. I may take Max up on his invite and see if I can get down to "Sunny & warm" sometime in the spring. I would love to get a glimpse of the light that waits at the end of the tunnel (if we do things right).

camsr, post: 299583 wrote: my 2 cents, the ceiling must absorb a

camsr, post: 299583 wrote: my 2 cents, the ceiling must absorb as much bass as possible. it should also provide diffusion and a fair amount of absorption so the instruments do not bleed when not desired. its especially important the least amount of bass possible bleeds into other mics, and this is most important on the ceiling, as its the smallest dimension and the resonance is higher, making filtering during mixing less effective.

Ceilings do not absorb bass as a matter of function. Depending on who designed it and what type of environment they had thrust upon them, actual bass trapping was included in the ceiling cavity. But it can go anywhere you have the space...sound is three dimensional, right?

In fact, in an accurate build, the ceiling is not any different from any other hard boundary. An overhead cloud, however will limit some of what you might be dealing with, e.g. reflections from the ceiling. It is a common practice when ceiling height is limited. As to this being the smallest dimension, this is also not the case. It is exactly the same often as the floor:) Difference is, as you said, people do not want the reflections from the ceiling getting into the mics.

camsr, post: 299583 wrote: ... the volume behind them can double as basstraps by putting mineral wool on the wall and a slight air gap between each structure. this will improve the resonances by widening their Q instead of acting as an unpredictable diffusor, much as splayed walls do.

Two things: A slight air gap between each structure is room in a room. So that is a no brainer. But the unpredictable diffusion from splayed walls is pretty predictable. It [splayed walls] mitigates the modes of a room and helps to generate a more even response overall.

Not everyone is a believer in splaying the walls. Some want to hang on to a rectangular environment for want of what they may perceive as a "tried and true" testimonial.

The people here that design and the people elsewhere that are highly noted for design all incorporate splayed boundaries.

That should be your bench mark.

splayed boundaries are good, just harder to calculate. they have

splayed boundaries are good, just harder to calculate. they have the effect of shifting the nodes of the lowest resonances. as the room appears larger to higher frequencies, the resonances begin to break and seek new paths. this improves the efficiency of absorption and edge difffracting devices for low resonant frequencies. one important point in a tracking room is if a large amount of partitions such as gobos are used, the shell boundaries become less prominent in their influence. but the ceiling reflection zone is not blocked by your standard gobo, and therefore is very important key to the sound of the room. you could slope the ceiling, dvdhawk, but i do think you will want to save as much height as you can. a ceiling cloud type system would be much easier to implement and save height in the room. while i do have my own ideas, this is dvdhawks project and we are here to advise him.

Space, post: 299749 wrote: I'm not here to advise. I am here for

Space, post: 299749 wrote: I'm not here to advise. I am here for clarification :)

I'll take all the advice, suggestions, experience, clarity, cautionary tales, I can get.

I may not follow any of the suggestions, but I would like to make informed decisions - having at least considered and weighed my options.

Keep them coming.

Concrete Pump-a-palooza starts in about 30 minutes. The opening

Concrete Pump-a-palooza starts in about 30 minutes.

The opening act sucked. It involved a guy with a snow shovel and another guy pushing snow with a skid-steer.

UPDATE: Pump-a-palooza has been postponed until Monday. The headliner "Pump" had a family medical situation.

Hold on to your tickets, they will be good for admission to the Monday show.

Return of the Putzmeister Pump-a-palooza got underway this morn

Return of the Putzmeister

Pump-a-palooza got underway this morning right on time under mostly sunny blue skies. ( so it didn't feel like 20˚ )

It's the fifth time we've needed a big ole concrete pump truck, and it's still just as impressive to watch as the first time.

42 CY of concrete today in the walls. Easy over the doors a

42 CY of concrete today in the walls.

Easy over the doors and windows until everything is filled and vibrated in below.

With the walls about 3/4 full of concrete they pull a line and use the turnbuckle style braces that hold up their walkway to make sure everything is straight under-pressure.

PITA, post: 300056 wrote: Very interesting process. I'll go back

PITA, post: 300056 wrote: Very interesting process. I'll go back to lurk mode now. BTW whats the total yardage of concrete at right now ?

32 CY in the footing

22 CY in the basement slab

81 CY in the basement walls (exterior walls 10" core + interior walls 6")

42 CY in first floor - floor

42 CY in first floor - walls

which puts us at about 220 CY, with about 22 more to do the 2nd floor walls.

The 2nd floor will go up another 9ft. above the garage and stairwell area.

The back portion will stop at it's current height of 10' 6" and use scissor trusses to get a vaulted ceiling.

The next step is put in the floor joists and 3/4" OSB for the 2nd floor. Then they'll be able to put in the last of the ICF. This last bit should go really fast with no door bucks to work around and no intersecting walls - just 4 corners and straight walls. The only obstacle on this floor will be several windows, but that's relatively easy.

Cost looks somewhat comparable to stick framing, labor looks low

Cost looks somewhat comparable to stick framing, labor looks lower and higher at the same time. Keep us posted ! I will now return to full lurk mode.

dvdhawk, post: 300062 wrote: 32 CY in the footing

22 CY in the basement slab

81 CY in the basement walls (exterior walls 10" core + interior walls 6")

42 CY in first floor - floor

42 CY in first floor - wallswhich puts us at about 220 CY, with about 22 more to do the 2nd floor walls.

The 2nd floor will go up another 9ft. above the garage and stairwell area.

The back portion will stop at it's current height of 10' 6" and use scissor trusses to get a vaulted ceiling.The next step is put in the floor joists and 3/4" OSB for the 2nd floor. Then they'll be able to put in the last of the ICF. This last bit should go really fast with no door bucks to work around and no intersecting walls - just 4 corners and straight walls. The only obstacle on this floor will be several windows, but that's relatively easy.

Honestly PITA I think cost-wise it's about a 'push'. Materials

Honestly PITA I think cost-wise it's about a 'push'. Materials maybe a little higher, labor I believe is substantially lower.

So sum up; I would have had the same cost in the footer & slab, additional engineering expenses in designing a 12ft. deep cinderblock basement wall. It would have taken significantly less concrete to do the first floor - floor, but then you'd have to add back in significant cost of the steel I-beams. If I were simply trying to cut costs, I could have gone 'stick-built' for the walls of the garage area and 2nd floor above - but opted for the more monolithic method. I think the difference will be made up over time in energy savings.

Only time will tell if I've saved myself any expense in multiple layers of drywall and green glue.

Lurk on! but feel free to chime in anytime!!

my thought on the labor is that its alot less hours but maybe mo

my thought on the labor is that its alot less hours but maybe more per man per hour.

back to lurking

dvdhawk, post: 300155 wrote: Honestly PITA I think cost-wise it's about a 'push'. Materials maybe a little higher, labor I believe is substantially lower.

So sum up; I would have had the same cost in the footer & slab, additional engineering expenses in designing a 12ft. deep cinderblock basement wall. It would have taken significantly less concrete to do the first floor - floor, but then you'd have to add back in significant cost of the steel I-beams. If I were simply trying to cut costs, I could have gone 'stick-built' for the walls of the garage area and 2nd floor above - but opted for the more monolithic method. I think the difference will be made up over time in energy savings.

Only time will tell if I've saved myself any expense in multiple layers of drywall and green glue.

Lurk on! but feel free to chime in anytime!!

Today's progress wouldn't be obvious from the outside, but the G

Today's progress wouldn't be obvious from the outside, but the GC and his crew got all 31 the 23ft. long Open Joists installed over the garage. (They're on 12" centers due to the length)

2-pc. brackets secure the ledger board to the wall. One part was embedded through the ICF and into the concrete. The second part wraps around to secure the ledger board to the wall, and Simpson hangers hold the OJ to the ledger board.

This south wall of the stairwell bears the weight of the other end of the long joists. 1/2" anchor bolts embedded vertically in the concrete hold the sill plate to the top of the wall. Tomorrow I'd expect the rim-board to go in and a couple strong-back 2x4s on this side then the other.

The shorter joists for over the mechanical room / bathroom / stairwell area will have to be trimmed to length and will span from the other side of that same sill plate and rim-board to the north wall of the stairwell - where you see the vertical rebar in the background. There are only 13 of them (most on 16" centers), so if all goes well they should start laying down the sheeting for the floor tomorrow too.

OH Man! Lookin' GREAT! And you wonner why I said you've got a k

OH Man! Lookin' GREAT!

And you wonner why I said you've got a killer build going on?!?!?

These guys know their stuff!

Because the foundation and early stages are being done so well, the work that's gonna come afterward is going to be easy to continue in the same path.

Everything starts with a good foundation... you get that right, and everything else tends to fall in place!

I'd love to have seen pump-a-paloosa. I bet that was a killa' act!

Max, Pump-a-paloosa ROCKS! Are you sure you don't need a couple

Max, Pump-a-paloosa ROCKS! Are you sure you don't need a couple hundred yards of concrete?

Friday's Progress was what we expected. My buddy the GC has been dealing with some bad news, but his crew showed up and got down to business. They got the rim board in and the short joists in and starting with the T&G OSB, got about 2/3 of it in. They should be able to finish that up Monday. Tuesday the ICF will resume.

Lookin' good. Very good. Just curious, do they cover the T&G to

Lookin' good. Very good. Just curious, do they cover the T&G to keep weather off while they finish or do they leave it open? I had a helluva time keepign the weather off mine. Then again I didn't have a crew building, just me, so it took a lot longer and a lot more weathering time.

Again it looks absolutely great!

Thanks Mr.M, We knew it would inevitably get wet before we got

Thanks Mr.M,

We knew it would inevitably get wet before we got it covered up, so the General Contractor recommended we use an OSB that is treated with some sort of additional water-resistant wax compound. I think all OSB uses wax and resin, but this allegedly has a little extra protection, the edges especially looked like they had a thick coat of something. It's Weyerhaueser Gold - Theoretically this OSB can be exposed to the weather for a normal construction cycle, plus a little more if necessary, but we're hoping it will be under-roof within a week or two.

We're starting to look something like a garage now!! Everybo

We're starting to look something like a garage now!!

Everybody's kicking to the finish line on the 2nd floor.

BAM! 33ft up - 0 feet to go. [12 below grade / 21 above grade] Formed up, framed in, and ready to pour. The next concrete pump truck won't be available until Monday.

A birdseye view of the 2nd floor - bonus space - office, lounge, conference.

We're expecting more snow for the 2nd half of this week - so we'll see what happens.

After that we got a thousand things to do - starting with:

A) get a roof on this thing,

B) put in the crucial exterior doors,

C) water-proof the below grade portion,

D) start working on the backfill,

E) stop to catch my breath,

F) perform CPR on my wallet

There are still a few random building materials downstairs in the control room, and no kidding, it already sounds better than some studios I've worked in. The completely untreated, undivided, totally empty tracking room has a cavernous reverb as is - but I'm not at all worried about that. I'm hoping the 33ft. stairwell ends up with a nice natural reverb too.

Lookin' good, mista cah-ter! (That is my Vinnie Barbarino impre

Lookin' good, mista cah-ter! (That is my Vinnie Barbarino impression - rough I know)

Seriously, moving right along.

I am curious what it looks like from the back. When I finished mine it was 30ft on the backside and I just couldn't believe it was standing in from of me. Yours is truly awe inspiring cause it is a FULL 3 floors!

I hope the snow misses you. It's hittin here now, maybe it will snow itself out.

Rock!

mrmelody, post: 300733 wrote: Seriously, moving right along. Ap

mrmelody, post: 300733 wrote: Seriously, moving right along.

Apparently not fast enough to suit Space :-) Just over 2 months from "hole in the ground to 4500 sq.ft. structure. Space, if there's a downside to having contractors who work quickly - it's that they expect [and deserve] to be paid just as quickly. I've been Mr. "pay as you go" to this point. So the 'studio part' will begin after I recover from the current workload and replenish some funds. I've been working myself to death - doing what I know how to do - trying to make the money it takes to pay these guys to do what they do better than I could. So I'll need to regroup after we're under roof, try to get some sleep, and see what I can afford to do next. I've got tons of work lined up, and hope to stay out of debt as much as possible on this thing. But all I can do is all I can do. So, patience my friend... patience.

mrmelody, post: 300733 wrote: I am curious what it looks like from the back. ... cause it is a FULL 3 floors!

Well, not quite. The 2nd floor is only over the front 2/3 of the building. The back portion quits at 10' 6", one floor above ground level, but it will have a vaulted ceiling with about 16ft. of inside height.

VIEWS FROM THE BACK AND SIDE - AS REQUESTED

mrmelody, post: 299039 wrote: Looking good! Definitely going qui

Thanks. It's going up very quick now. The weather has been a bit of a factor, but not too much. The crew has been working pretty steady for about 6-7 weeks and we have had just enough nice days to get the concrete poured and covered up. You're not too far away, so you've had about the same weather.

I'll grab some more pictures tomorrow. They got their bracing/walkway up today and should be stacking Legos again tomorrow.