Friends,

Not long ago I bought a mic cable for some recording I would be doing. It was a Rapco Cable, a new modle of some kind. Any way, I get my condenser mic and new cable hooked up to my interface, and I don't get any signal. After some trial and error I decided to plug a cheap Nady dynamic mic up to the cable and interface, and sure enough I got signal. My heart nearly stopped because I thought that my condenser mic had gone bad, so I borrowed a cable from a friend to check the mic. I used THE EXACT setup as before only switching the cables, and I GOT signal. This really boggled me. The problem I assumed was in the cable.

I took the cable back to the store. I told the manager my situation and before I could finish telling him my story he stops me, and says "Oh, it's not the cable we sold you, you just didn't have your phantom power on." I thought to myself, "Really, this guy thinks I didn't check that!" I then explained that a different cable that I borrowed worked for me. He then decided to run some tests on the cable. He first plugged it up to a dynamic mic. It worked. Then he plugged it up to a condenser (making sure his phantom power was on), and surprise, It DIDN'T work. Fe fiddled around with things, but the cable wouldn't power a condenser mic. He switched me for another Rapco cable (an older modle), and things are running great.

Why would a cable work with dynamic mics but not condensers? The only thing I can figure is some kind of bad connection. Has this happened to anyone else? If it is something I might have done let me know so it doesn't happen again. I run these through a Tascam 144 interface. That wouldn't fry a cable, would it?

A riddle indeed.

Happy recording

Topic Tags

Comments

Under a few special conditions, the shield at the far end may no

Under a few special conditions, the shield at the far end may not be connected (or connected through a capacitor called a hybrid shield). This of-course won't work with a mic cable. The main use for these special cables is when going from a building to another building that has a different AC power source.

If I remember correctly, pins 2 and 3 are responsible for carryi

If I remember correctly, pins 2 and 3 are responsible for carrying the signal. Pin 1 is the shield. When the phantom power is on it also acts as the reference voltage. If pin 1 was not connected, a dynamic mic would still work, but there might be some electrical interference. However, phantom power would not work.

Thanks a lot guys. If helps to be able to explains something lik

Thanks a lot guys. If helps to be able to explains something like this actually knowing what up. I'm still curious if this happens a lot. You would think they run tests before they ship these wires out. Is there a particular cable that You prefer? I defiantly stay away from the cheap ones (a got a pretty terrible cable off Musicians Friend once). At work we use Pro Co cables we get from Sweetwater. I've never had problems with them.

nathansmind, post: 348271 wrote: Is there a particular cable tha

nathansmind, post: 348271 wrote: Is there a particular cable that You prefer?

The ones I build myself.

Not only can I get better components than those found on many of the commercial cables from ProCo, Rapco, Monsterco, etc (or equivalent components for less money), but I also get the peace of mind of knowing my cable was built by a professional who had the patience to fully QC the finished product.

Plus I find soldering to be therapuetic; it's the equivalent of meditation.

Did you do a visual inspection, or use a tester to confirm one e

Did you do a visual inspection, or use a tester to confirm one end is wired wrong?

Rapco is generally a good cable, but they are soldered by humans. Mistakes will happen especially by a new hire - but I agree they SHOULD check them before they ship them.

Generally ProCo, Rapco, Whirlwind all make very good general purpose stage & studio cables.

Mogami and Canare are considered to be the go-to companies for studio quality cables.

I agree with Buster. Soldering skills will serve you well over

I agree with Buster. Soldering skills will serve you well over the duration of your music/recording career.

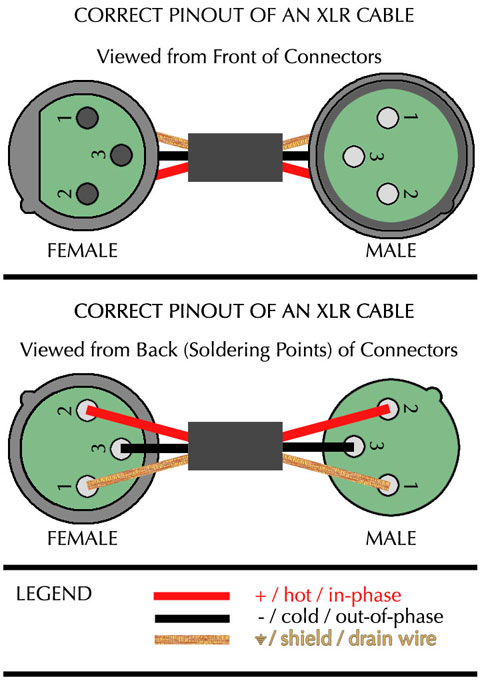

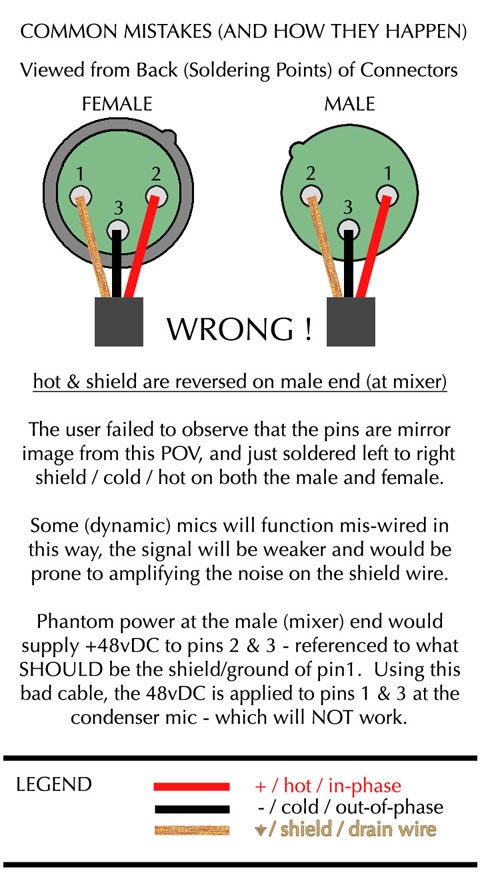

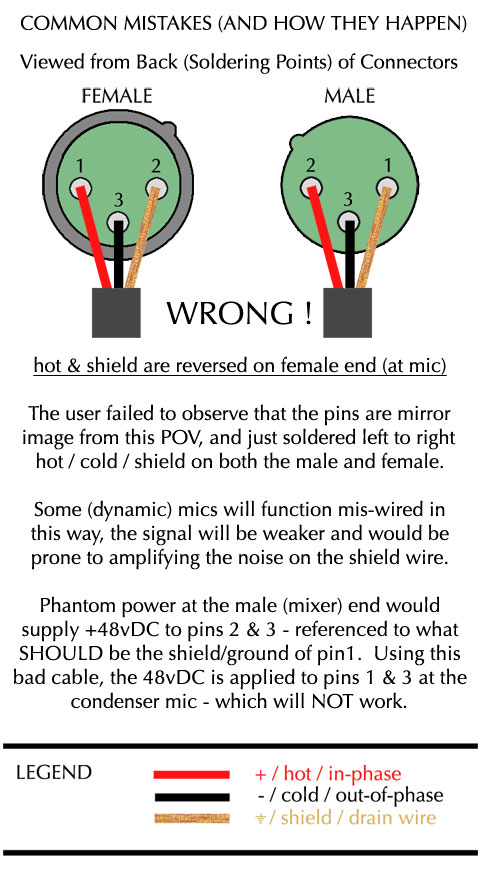

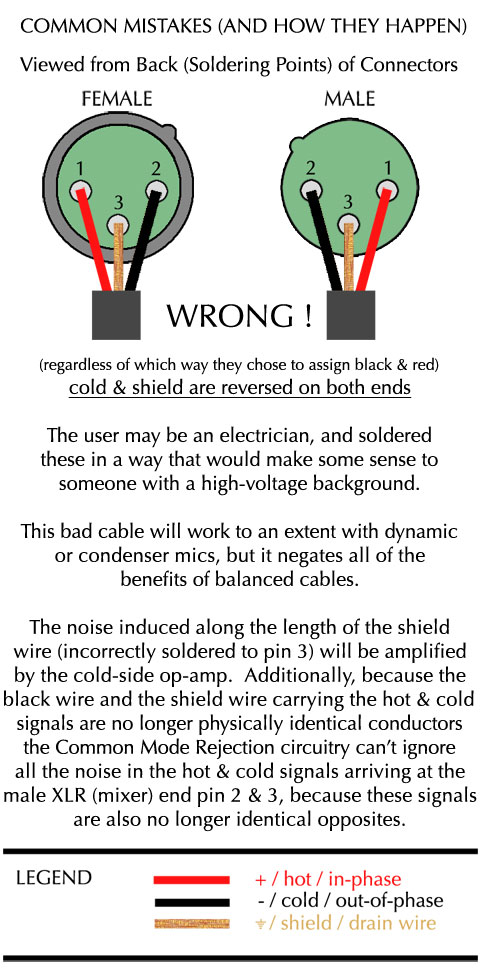

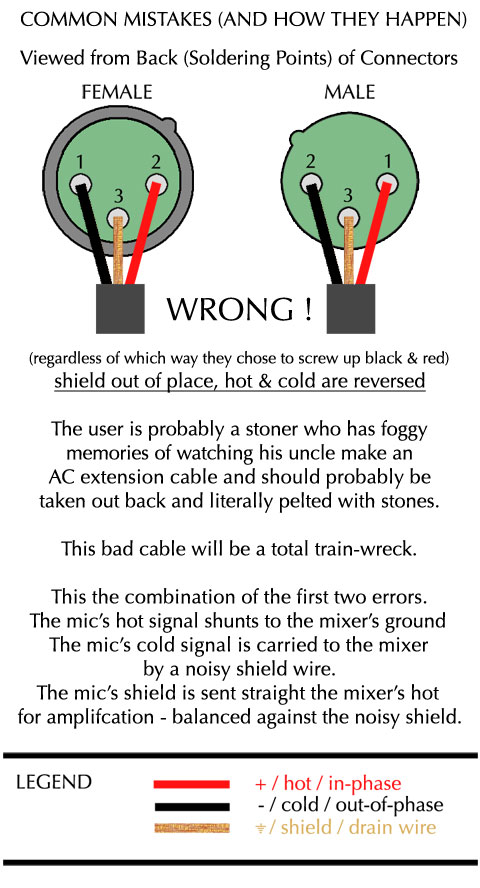

Here are some graphics I hope will help you in your pursuit of this cable problem - and if you decide to take up a soldering iron yourself. Please note I used black and red as reference colors, the color coding of your cable may vary. Rapco often uses red and blue. Good luck.

Materials can be had from numerous sources like Markertek, or Sw

Materials can be had from numerous sources like Markertek, or Sweetwater etc. For a guide in what wire gets connected to what check out this Rane white sheet:

[[url=http://[/URL]="http://www.rane.com…"]Sound System Interconnection[/]="http://www.rane.com…"]Sound System Interconnection[/]

You usually have to buy a pretty large quantity of connectors to

You usually have to buy a pretty large quantity of connectors to get a great price. So from that perspective, if you're only talking about a few cables - you may be just as far ahead to buy them pre-made. But if you are looking to learn, or hone your soldering skills, it's time and money well-spent. And there's no excuse for not repairing things like that when they go bad.

[="http://www.parts-express.com"]Parts Express[/]="http://www.parts-ex…"]Parts Express[/] is a good source for Neutrik XLR connectors. They're so-so on bulk wire.

[[url=http://="http://www.redco.com"]Redco[/]="http://www.redco.com"]Redco[/] is a good source for your higher quality bulk wire. They're a little higher priced on the standard connectors, but they've got some of the hard to find things you don't see anywhere else.

Thanks for the links Dave - as a budding studio owner/operator (

Thanks for the links Dave - as a budding studio owner/operator (still consider it a "project"), I realize the importance of these types of things.

Cabling/connectors are critical in this biz.

Say I want to run a bass DI through a comp before my preamp?

Well, this preamp only has XLR i/o, while the comp has both XLR and 1/4". My snake is XLR, so it goes to the comp - now I need something to connect it to the pre.

XLR? No, they're all in use. 1/4" to XLR(M) it is. Then I need an XLR(F) to 1/4" to go from preamp to interface. And that's just the chain for one channel!

How long do the cables need to be? Am I doing a long run or a short? Lot's of possibilities.

While having an assortment of cables, connectors, and the like is important... it's easier in the end to make what meets *your* needs.

And more importantly, to fix a loose/bad solder rather than pitch a perfectly good cable!

On the other hand, you have to look at this like any other busin

On the other hand, you have to look at this like any other business decision. You have to buy in quantity to keep marginal costs low. And you have to devote the time necessary to do the job. Is there is someone in your area that will make cables to order at a good price with a reasonable turnaround time? Do you have dead time that can't be filled more profitably than by making cables? If the answers are "yes" and "no" respectively then you probably should farm the task out. If it is "no" and "yes" then you should probably make the cables - and think about offering custom cable services as part of your business.

I learned how to solder when I was in my late teens, early 20s.

I learned how to solder when I was in my late teens, early 20s. Back then I had more time than I had money and it was cheaper to fix a broken cable than replace it. Now that I'm mid+40s, I have a little more discretionary income and virtually zero spare time, so I will buy mic and instrument cables if I just need something off-the-rack.

As a A/V contractor, I can buy cables at wholesale from a number of manufacturers. And even still as an installer, I end up making a significant number of cables, or at the very least soldering one end of a custom-length cable. Last night I was working on an install and I've got a big bin full of pre-made balanced patch cables. Some were used to patch connections in the back of the rack, others were cut in half to facilitate those idiotic Phoenix plugs and variety of terminal strips. The cable manufacturers I deal with are also a good place for me to buy connectors in bulk - but I'm buying XLRs in quantities of 50-100 each. That ties up a lot of money, but then I'm prepared for whatever comes along when the phone rings.

I'm constantly soldering in wallplates, floor-pockets - where you have no choice. In cases where you have to make custom snakes, and multi-pins, DIY is a REAL money-saver. The same would be true wiring up a studio, or cabling up a patchbay. Neat and tidy, everything permanent is made to length.

For me, build-it vs. buy-it depends on the situation, present workload, and type of connectors. I've gotten to where I'd rather make a half-dozen XLR cables, than one 1/4" cable. You have to be in just the right workspace to efficiently make a 1/4" cable. You have to plug the jack into something stable and be able to support the cable at the same height. Otherwise you end up pulling things out of whack, which will eventually put strain on one conductor or the other, leading to premature failure. I recently HAD to make four 12AWG speaker cables with Switchcraft 184 Jumbo 1/4" connectors - what a pain! The whole time I was thinking, "I would gladly pay someone else to do this" and "SpeakOn connectors Rock!, why would anybody buy 1/4" speaker cables in 2010?"

Well, I thought that I should report that I fixed my first micro

Well, I thought that I should report that I fixed my first microphone cable today. It was one I had sitting in a box collecting dust. I opened it up and one of the shields seems to have sparked. I resodered the connectors, and bam it works. I always thought it was taboo to take the covers off a mic connector, but now that I know what under there, I have no worries.

Thanks,

Nathansmind

Polycarbonate sheets provide a unique way of minimizing or elimi

Polycarbonate sheets provide a unique way of minimizing or eliminating consumption of energy for artificial electrical lighting in several application areas. Solar energy is naturally available and plentiful in a Country like India. Polycarbonate sheets offer you an opportunity to harness this bountiful source of energy, effectively and for years to come.

---------------------------------------------------

[[url=http://[/URL]="http://www.polycarb…"]False ceiling[/]="http://www.polycarb…"]False ceiling[/]

The cable is wired wrong from the factory - end of mystery. Do

The cable is wired wrong from the factory - end of mystery.

Do you own a ohm-meter and/or small screwdriver?

If it has Neutrik connectors, you don't even need a screwdriver to perform a visual inspection.

Look at it closely, find the tiny numbers on the connector. Pin #1 should ALWAYS be the shield wire (on BOTH ends). - I'm betting it isn't.

Don't forget the pinout is mirror image (backwards) on one end.

With an ohm-meter you should have continuity between Pin#1 on one end to Pin#1 on the other / Pin#2 to Pin#2 / Pin #3 to Pin#3.

And of course you can show it to the store manager, who should have tested and confirmed this for you.