Hi!

I have been slowly working on building out a new room in my basement for practicing/recording drums.

It's been a slow process, that has thus far involved removing water heaters, and breaking up the concrete floor to re-route the water main so that I have a relatively unobstructed floor space to work with.

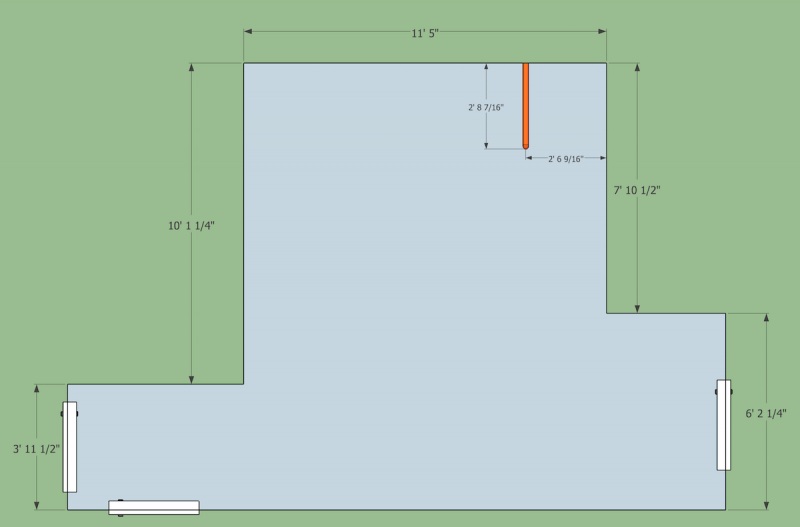

I have about 8' 4" from floor to the bottom of the ceiling joists, and about 11 1/2' x 14' of space to work with.

As a side note, the rest of the basement is finished, and the lovely wife isn't wild about me tearing that stuff apart as I do my build.

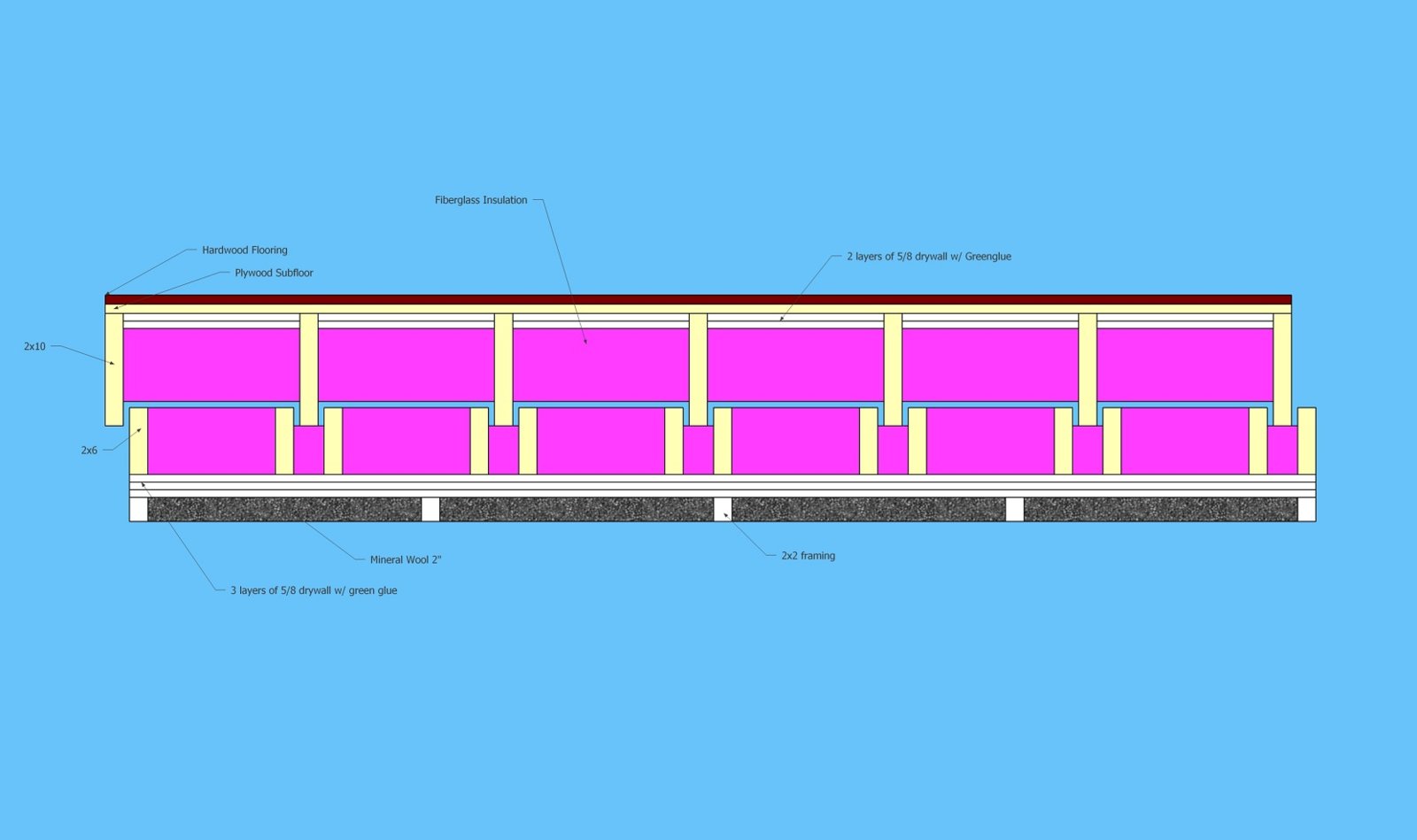

I have started beefing up the existing subfloor above my space using 'rods method' of adding two layers of 5/8 drywall between the joists, with green glue, and then battening them into place with 1x2.

My plan is to build the 'room in a room' and have a new "inner ceiling" supported by the new framing I build.

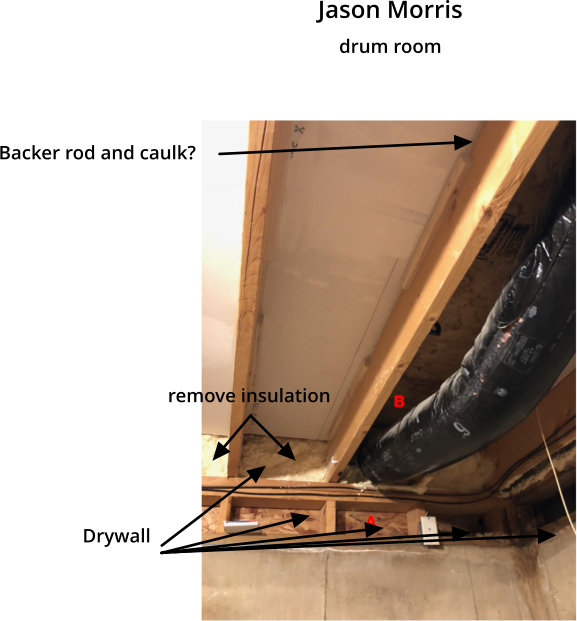

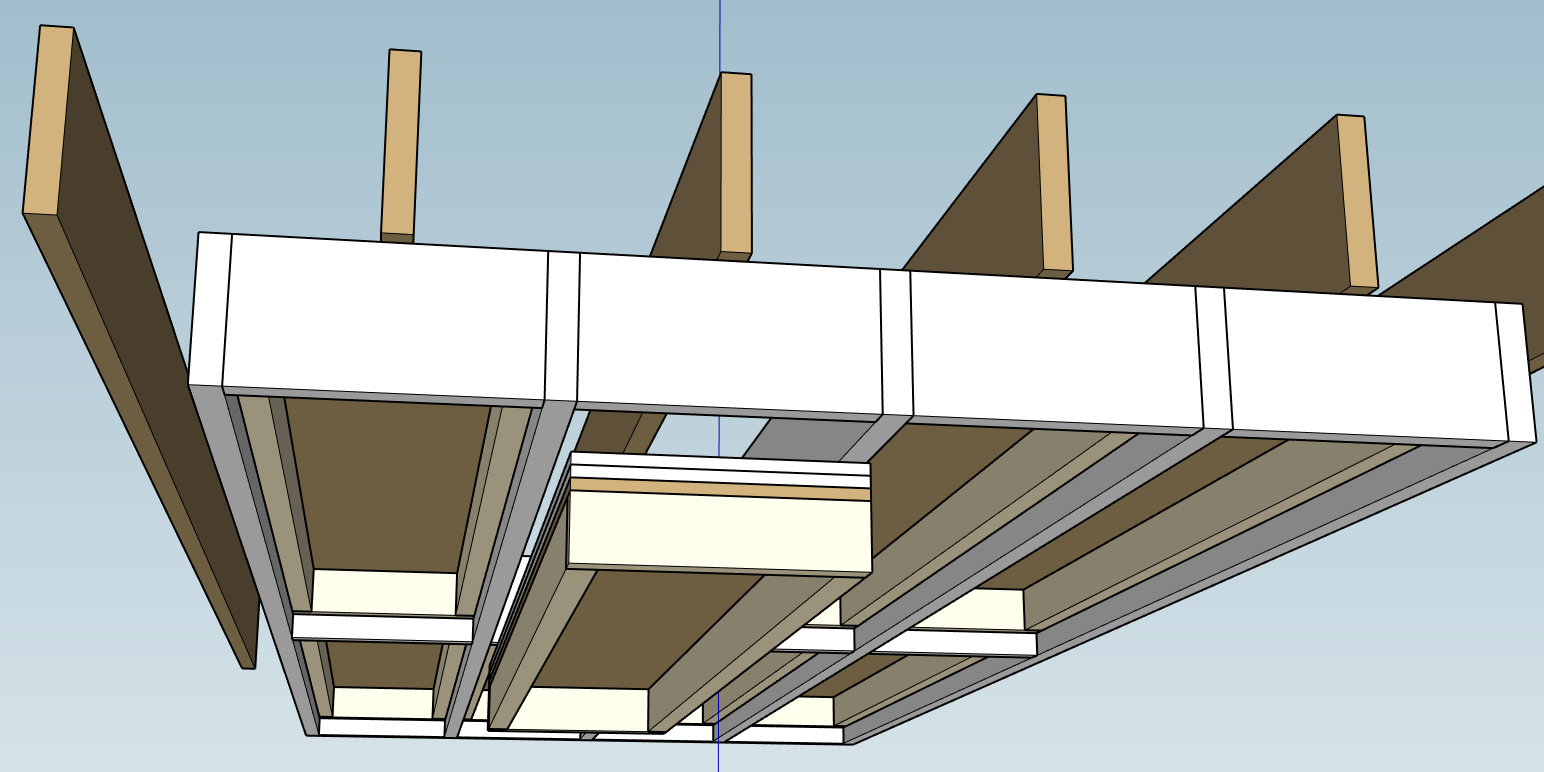

In the picture attached you can see what I have going on thus far.

My questions are:

In the attached picture, you can see a space (labeled A). On the other side of that is the brick veneer of my home.

If I seal that area up with drywall and acoustic sealant, am I essentially creating a small 3-leaf system once I have my drum rooms walls built? Should I fill that cavity with layers of drywall? just insulation? Or is it such a small space that I shouldn't be fretting about three leaves?

Also, Above this ceiling is our 'formal' dining room (not used much).

In the space labeled "B" you can see the ductwork feeding the vents in that dining room.

Keeping in mind that I AM going to be building that decoupled "inner" ceiling, what should I do about that duct and vent feeding the dining room?

Comments

Thanks RCRecord! Yep, that's pretty much exactly what I am plan

Thanks RCRecord!

Yep, that's pretty much exactly what I am planning on doing. I had not heard of Safe N Sound doors before. I will look into them. I am going to need two doors for my drum room, and one door from my "control room" to the rest of the basement.

When you built your studio did you have to deal with any duct work feeding the house above you? That's what I am trying to figure out at this point. The best way of dealing with that. My gut tells me that if I beef up the subfloor and use mineral wool insulation between the joists that by the time I build the rest of my "room-in-a-room" I wont have much sound being transmitted upstairs thru the flexible ducts. But I also dont want to put a bunch of $$ into the ceiling construction only to have it wasted because I neglected to do some simple thing correctly at this stage in construction.

Those ducts won't have anything to do with the ventilation of th

Those ducts won't have anything to do with the ventilation of the room I am building. I am planning on pulling in fresh air from outside with some inline centrifugal duct fans. Stale air would be blown out the other side.. maybe into the garage? Cooling/heating will be done with a mini-split system. At least that is my plan right now. :)

hey Jason, welcome to RO. congrats on getting the book, and hamm

hey Jason, welcome to RO. congrats on getting the book, and hammering thru the most tedious part of your build. i can relate to your pain, having gone throught the process on several builds. heres a couple thoughts i have regarding your posts.

Jason Morris, post: 456225, member: 51197 wrote: In the attached picture, you can see a space (labeled A). On the other side of that is the brick veneer of my home.

If I seal that area up with drywall and acoustic sealant, am I essentially creating a small 3-leaf system once I have my drum rooms walls built? Should I fill that cavity with layers of drywall? just insulation? Or is it such a small space that I shouldn't be fretting about three leaves?

i was having a hard time visualizing things from the picture. i annotated your pic, to show generally where the drywall should go. make sure its staggered layer by layer at the juncture where the ceiling bay drywall and the wall bay drywall meet. its pictured in the book. three leaf systems should be avoided whenever possible regardless of size. if it has to be, se la vi, but otherwise the effort should be made to not have them. i believe theres a couple three leaf wall sections at the Powerstation NE, but i am not sure which ones.

Jason Morris, post: 456225, member: 51197 wrote: Also, Above this ceiling is our 'formal' dining room (not used much).

In the space labeled "B" you can see the ductwork feeding the vents in that dining room.

Keeping in mind that I AM going to be building that decoupled "inner" ceiling, what should I do about that duct and vent feeding the dining room?

if its possible to re-route it, that could be the quickest easiest solution. you have two options if the duct has to stay, presuming the ducting isnt the same diameter/width as the joists. put the drywall above the duct, tight to the deck, like you did on the other bays, or pad out the void in the bay that surrounds the duct, then install the drywall in the bay, so the duct is buried. that would be my preferred order to those methods.

as an aside you may want to look at it as an opportunity to upgrade to an insulated solid duct, which is much more efficient that flexible. i dont believe rod recommends soft ducts for anything.

it would also help if you had a sketch of the basic floor plan/layout because its difficult to feel oriented otherwise (for me st least).

also, i wanted to verify your using backer rod and (non hardening) caulking the gap between drywall and joist. an FYI, not sure if your using the temp nail/ledger board method, or screwing the drywall directly into the deck. where applicable, ie you wont screw thru floor above, you may be able to save some time doing it this way.

anyway, congrats on your build, the obsessive attention to detail required, is worth it in spades, every single second your in that studio.

Jason Morris, post: 456227, member: 51197 wrote: My gut tells me

Jason Morris, post: 456227, member: 51197 wrote: My gut tells me that if I beef up the subfloor and use mineral wool insulation between the joists that by the time I build the rest of my "room-in-a-room" I wont have much sound being transmitted upstairs thru the flexible ducts.

unless you need rockwool for fire code reasons, stick with standard fluffy R- value insulation. its cheaper, more efficient at absorbing bass. the slight db or so advantage. rockwool provides, is not worth it in wall cavities. save the money for when you need rigid fiberglass/rockwool for the acoustical finish treatment, thats where its best applied in studios, generally. insulation's job in a cavity, is simply to dampen resonance within the wall(s) cavitie(s). like adding moon gels to your toms. your isolation is gain thru decoupled, air sealed mass, drywall in this case.

just wanted to mention that when i thought of it.

Hey, thanks for responding Kyle! And thanks for annotating the p

Hey, thanks for responding Kyle!

And thanks for annotating the pic I provided.

So, if I am understanding you I should fill those small 6"x3"x5" cavities just above the concrete wall with drywall.

Also I should try to remove that insulation from the cavity above that.

I'm not sure how rough that will be. It's that blown in, glue-like stuff... Like "Great stuff" on crack... not the fluffy insulation.

Also, I AM using backer rod and Green-Glue acoustic sealant in the corners.

Regarding my ducts.. I'm not sure if re-routing is an option, because the way the room is built, there isn't really another place to route it in.

So I think my only option would be to not have any HVAC service to that room in the house. Personally, I don't much care, as the room doesn't get used a lot, but I feel that if I ever wanted to sell the place that could come back and bite me on an inspection and I'd potentially be required to put hvac back in the dining room.

I will think about it a bit though and see what the boss thinks of that idea.

I DO like the idea of replacing the ducts with insulated solid ducts. If I need to keep that service there, I will do as you suggested and rip out the flexible duct, add my two layers of drywall, backer rod, and caulk, then place solid insulated ducting in there.

Thanks for that suggestion.

I will try to get a new floor plan worked out in sketchup asap. I have an old sketch I did, but it included a "box" around a problematic water main that was exactly 2 feet into the middle of my drum room. I decided to break up the concrete and re-route that water main to the area that will be my "air lock" between the drum room and the control room.

I was unaware that the fluffy insulation was better at absorbing bass. In fact, I thought it was the other way around? Ugh. Every time I think I have a handle on this stuff, I find out I read something wrong. :D

Is there a particular R-value you would recommend for between the joists? Should the whole cavity be filled?

Thanks again for taking the time to respond to my numerous questions. I apologize if I'm too wordy. I'm just trying to make sure I know what I'm doing.

My new wifey and step-kids did NOT grow up with my drumming, so I really want to make the space I have available as isolated as I possibly can, within the confines of what she will go for, or course! even if it costs a bit more $$ or takes me a bit more time.

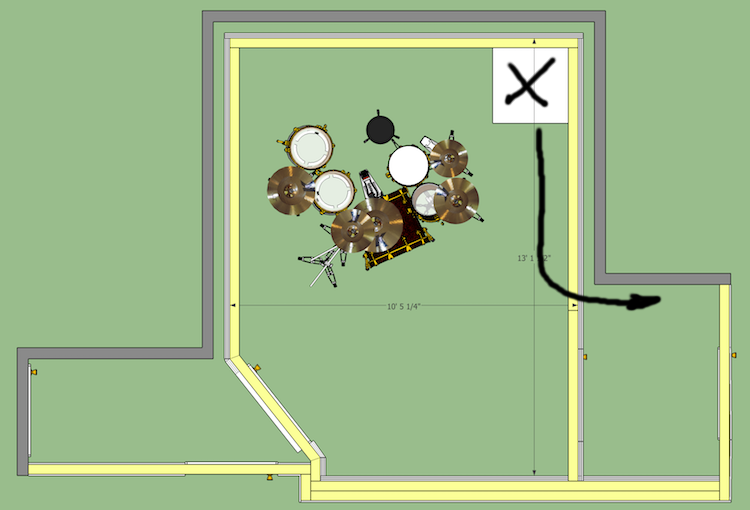

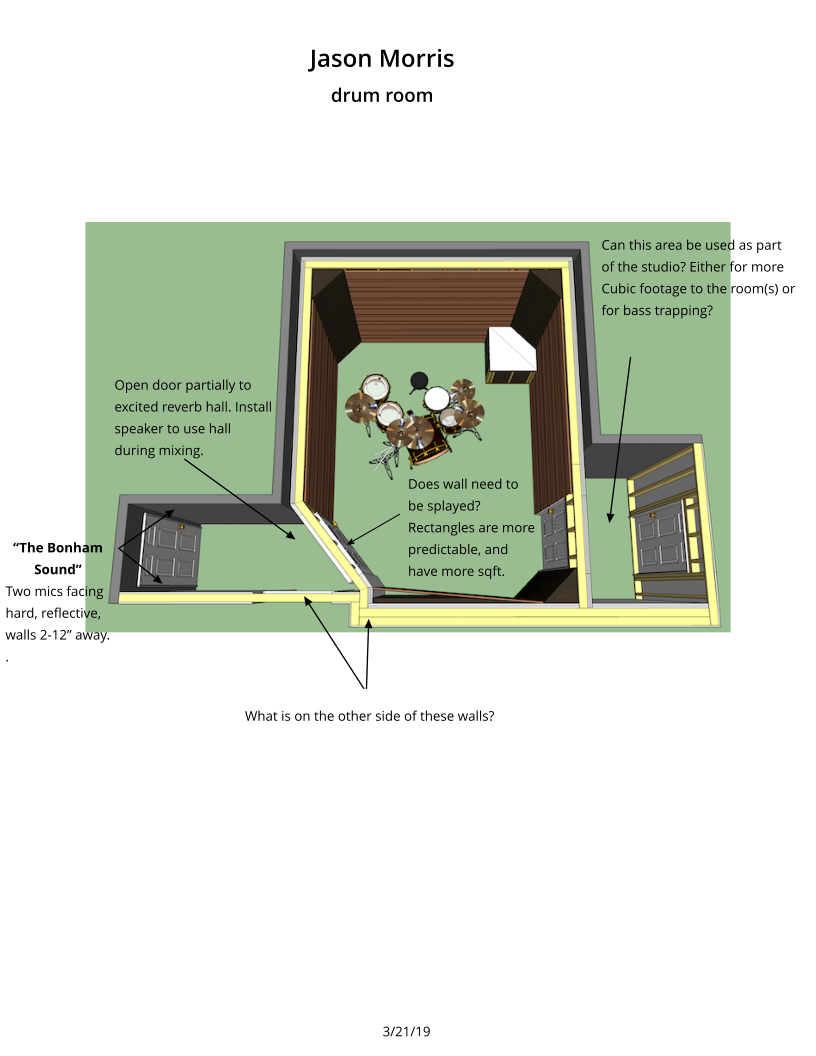

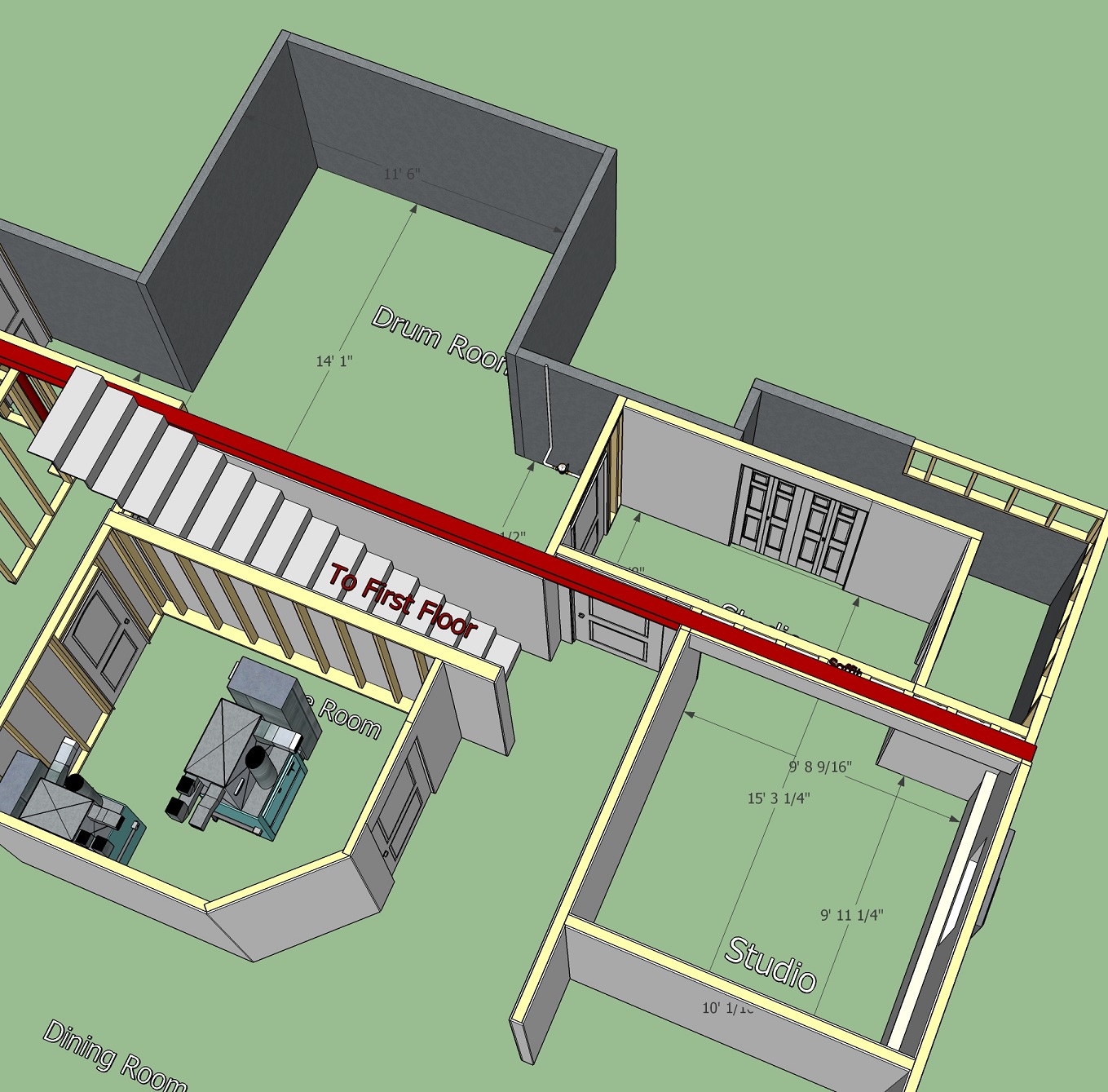

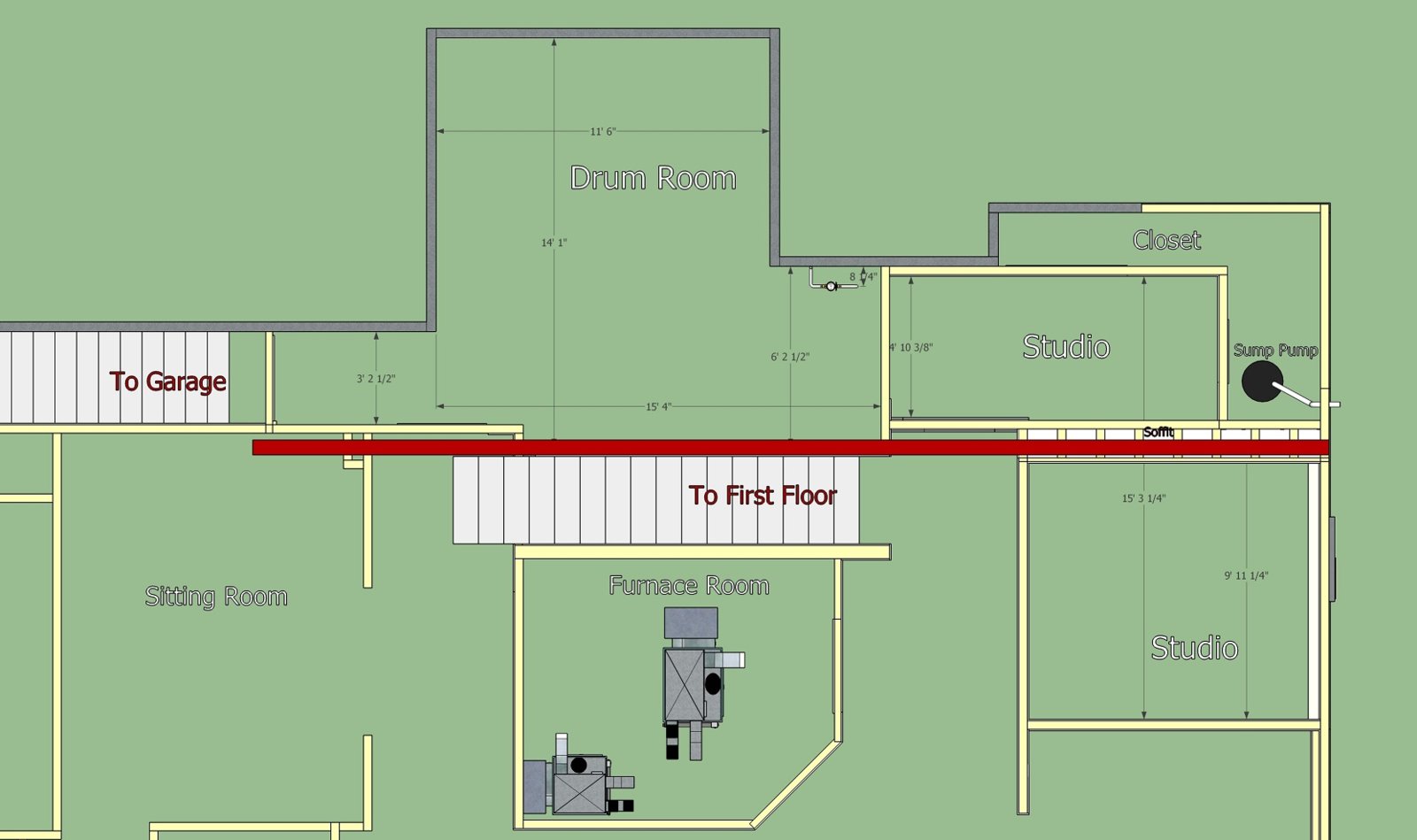

I went ahead and attached a couple of the old sketches I did for

I went ahead and attached a couple of the old sketches I did for my room.

At the time I did these, I was planning on an "inside-out" wall. After reading Rods book, I am wondering if I should should just build the walls an inch away from the existing concrete walls. I think it might be simpler and easier to seal up.

As I mentioned above, that box in the upper right is no longer part of the plan, as I move the water main around the corner.

The grey walls are concrete. To the left of my room is the garage, with the far left door leading to a flight of stairs going up to the garage.

As I said, I will try to update my sketch and add more detail this week.

Thanks again.

hey glad i can help. please excuse all the quotes, it helps me k

hey glad i can help. please excuse all the quotes, it helps me keep track.

Jason Morris, post: 456240, member: 51197 wrote: So, if I am understanding you I should fill those small 6"x3"x5" cavities just above the concrete wall with drywall.

yes.

Jason Morris, post: 456240, member: 51197 wrote: Also I should try to remove that insulation from the cavity above that.

I'm not sure how rough that will be. It's that blown in, glue-like stuff... Like "Great stuff" on crack... not the fluffy insulation.

what is behind that insulation? lol, if removing that insulation is as rough as it gets, you'll be the luckiest studio builder in history. if it comes down to it theres probably a 'best method' or trick, online. i hated wallpaper glue, and scotch tape resiudue, until i discovered murphys oil soap, and wd-40, melt that stuff away.

Jason Morris, post: 456240, member: 51197 wrote: Also, I AM using backer rod and Green-Glue acoustic sealant in the corners.

excellent! rods plans work, provided they're followed precisely. you can substitute the brand name 'acousitical sealant' for non-hardening silicone, or butyl caulking. save yourself some more money and buy it bulk, your gonna need alot of it. several cases gets expensive at $6 a tube.

Jason Morris, post: 456240, member: 51197 wrote: Regarding my ducts.. I'm not sure if re-routing is an option, because the way the room is built, there isn't really another place to route it in.

So I think my only option would be to not have any HVAC service to that room in the house. Personally, I don't much care, as the room doesn't get used a lot, but I feel that if I ever wanted to sell the place that could come back and bite me on an inspection and I'd potentially be required to put hvac back in the dining room.

I will think about it a bit though and see what the boss thinks of that idea.

tpypically residential hvac systems are overspec'd. theres a possiblity you could patch into some other ducting, perhaps in the attic, or thru the wall. Hvac is the area i know least about. in my experiences ducting either been there already, or we installed the ductless systems.

Jason Morris, post: 456240, member: 51197 wrote: I will try to get a new floor plan worked out in sketchup asap. I have an old sketch I did, but it included a "box" around a problematic water main that was exactly 2 feet into the middle of my drum room. I decided to break up the concrete and re-route that water main to the area that will be my "air lock" between the drum room and the control room.

where is the control room located? you are aware that air-locks diminish isolation a little right? just want to check.

Jason Morris, post: 456240, member: 51197 wrote: I was unaware that the fluffy insulation was better at absorbing bass. In fact, I thought it was the other way around? Ugh. Every time I think I have a handle on this stuff, I find out I read something wrong. :D

Is there a particular R-value you would recommend for between the joists? Should the whole cavity be filled?

im in over ten years, 6 studios, and taking graduate level physics online, and still scratching the surface of the acoustics world.

the R-value is whatever code calls for in those joists (which are 2x??). not sure how many layers of drywall your planning on, (with drums id be planning three), but you may have to use something sized down, if the drywall in the bays, and the ceiling design calls for it.

are you still planning an independently framed ceiling?

Jason Morris, post: 456242, member: 51197 wrote: At the time I did these, I was planning on an "inside-out" wall. After reading Rods book, I am wondering if I should should just build the walls an inch away from the existing concrete walls. I think it might be simpler and easier to seal up.

having only done it Rod's method, i can only attest that it works as prescribed. any time ive inserted my 'bright ideas' without verifying with an acoustician, it hasnt worked like i wanted. fortunately it only took a couple fails to learn. Rod generally describes the most efficient way to do everything. Its a great resource an had an immensely positive effect on my life and work.

i attached your sketch with some of my thoughts on it, some things are easier to express right on the pic.

I really want to make the space I have available as isolated as I possibly can, within the confines of what she will go for, or course! even if it costs a bit more $$ or takes me a bit more time.

i cannot stress how crucial this attitude is towards having it done right and within a reasonable budget. theres alot of planning involved, but willingness to take the time will pay dividends in the end. you never regret doing it right, and you'll only cry once at the bank. theres nothing worse than 'if i only had....' once the place is built and the budget is used.

have you taken some sound meter readings with and without you playing? do you have a working budget? what other rooms or gear are involved in the studio? do you have your electrical, lighting, and wiring planned? not trying to be overbearing, just trying to get a feel for the whole scope of the project, since its as strong as its weakest link. (enough cliches for ya? lol)

i always enjoy when people are willing to put in the effort and do these things right. there's too many hacks and myths out there.

cheers!!

kmetal, post: 456256, member: 37533 wrote: what is behind that i

kmetal, post: 456256, member: 37533 wrote: what is behind that insulation? lol, if removing that insulation is as rough as it gets, you'll be the luckiest studio builder in history. if it comes down to it theres probably a 'best method' or trick, online. i hated wallpaper glue, and scotch tape resiudue, until i discovered murphys oil soap, and wd-40, melt that stuff away.

Behind that insulation is whatever sheathing is attached to the house, and then the brick veneer.

I haven't really tried to remove the insulation yet, and if that's what I have to do I will bite the bullet and figure out how to get it out of there.

However, I have been browsing around and I thought that I saw a post of Rod's where he talked about filling voids like that with closed-cell spray foam, which is what that is.

I realize there is no acoustic absorption benefit to doing so, but my understanding was that it would couple the drywall that I plan to install over those cavities to the sheathing on the other side of that cavity so they become "one leaf", thereby alleviating the "three-leaf" problem.

That was my thinking, but if you are pretty sure it's a better idea to scrape all that spray foam out of there and fill it with drywall, I'll get to scraping!

kmetal, post: 456256, member: 37533 wrote: several cases gets expensive at $6 a tube

$6? I'd love to pay 6 bucks! I've been paying 8 a tube for the Certainteed Green Glue from Menards.

kmetal, post: 456256, member: 37533 wrote: where is the control room located? you are aware that air-locks diminish isolation a little right? just want to check.

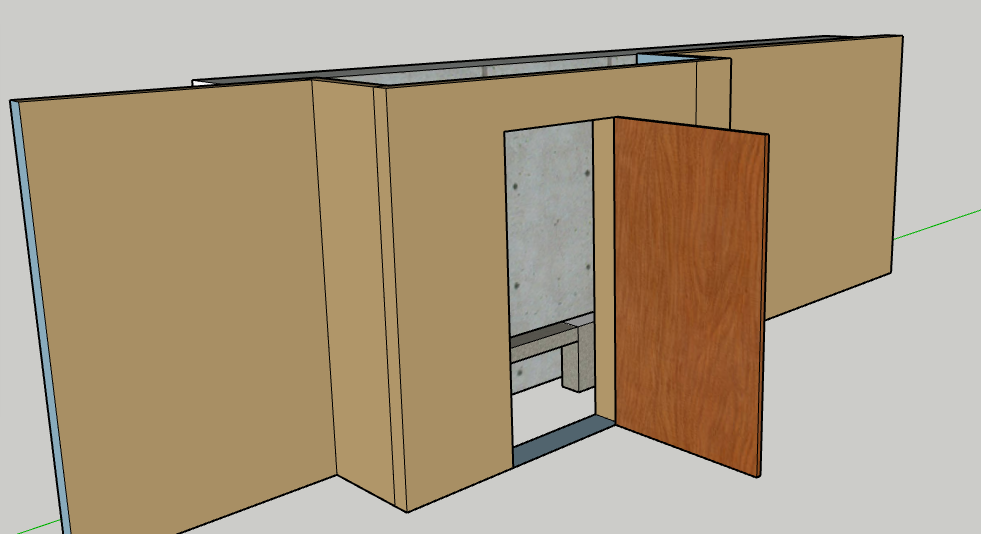

I was NOT aware that an airlock would diminish my isolation! Thank you! The "Control room" is really a pretty loose term for just a finished part of the basement that I have my gear set up in. The wifey was not keen on me ripping and rebuilding that whole area from scratch, as it was nicely finished, but she has become far more accepting of the ideas of adding drywall and acoustic treatment. I just had a door frame framed out last week so I can isolate that area a little more from the rest of the finished basement. It's not ideal, but it's what I have to work with. I attached some pics to give a better idea.

kmetal, post: 456256, member: 37533 wrote: are you still planning an independently framed ceiling?

Yep!

kmetal, post: 456256, member: 37533 wrote: have you taken some sound meter readings with and without you playing? do you have a working budget? what other rooms or gear are involved in the studio? do you have your electrical, lighting, and wiring planned? not trying to be overbearing, just trying to get a feel for the whole scope of the project, since its as strong as its weakest link. (enough cliches for ya? lol)

I have indeed taken some measurements.

My playing in the drum room is about 118DB when I am really whacking them.

Around the house, I got the following readings

Dining room (directly above the room I'm building the drum room in): 88 dB

Living Room: 72dB

My Sons room which is in the finished part of the basement: 86dB

The electrical panel is in a closet at the back of the room I am using for a control room. I haven't got the routes planned yet, but am planning on surface mounted boxes to cut down on the number of penetrations.

I have put some thought into running the other wiring. Planning on running PVC pipe from the control room to the live room. Not a straight run of it, but with a few bends, and maybe rubber couplers to help alleviate transmission noise thru the PVC.

Looking to cable for maybe 16 mics, 4 headphone returns, and a couple of ethernet cables, as I think if I build this right I should have terrible wi-fi coverage in this room.

And you are absolutely NOT being overbearing. I can't tell you how much I appreciate your input on this.

Regarding the comments on the picture.

I love the idea of using that hallway as a reverb chamber. Had not even considered that. Who doesn't love the "When the Levey Breaks" drum sound? Neat!

The other side of that wall is a closet, the stairway going upstairs (closet its beneath it). On the other side of the stairs is the furnace room, which is central to the basement. The other finished areas of the basement are around that. I'll try to draw things out more completely this week.

That area that I was planning on using as an Air Lock.. that could absolutely just be included as additional square footage in the drum room. However, that IS the area where I had to put that problematic water main/meter. If you dont think thats gonna be an issue, I will gladly extend the drum room into that space.

I have attached some more pics to give a better idea of what I am working with.

As a side note, the carpeting the the "control room" is going to be taken out.

Jason Morris, post: 456259, member: 51197 wrote: I realize there

Jason Morris, post: 456259, member: 51197 wrote: I realize there is no acoustic absorption benefit to doing so, but my understanding was that it would couple the drywall that I plan to install over those cavities to the sheathing on the other side of that cavity so they become "one leaf", thereby alleviating the "three-leaf" problem.

That was my thinking, but if you are pretty sure it's a better idea to scrape all that spray foam out of there and fill it with drywall, I'll get to scraping!

if you can somehow be absolutely sure that cavity is sealed, then add more blow foam and cut it flush with the studs, if you add drywall on top, itll be considered one leaf. it may require you to space the wall off the foundation an extra inch or so, which isnt the worst thing. its either that, or is gotta be taken out. if left as is, its a huge breach in the isolation. my prefernce is to remove it. it gives a chance to peek into the cavites for pipes, wires, and bodies, while keeping variables to a minimum.

Jason Morris, post: 456259, member: 51197 wrote: I have indeed taken some measurements.

My playing in the drum room is about 118DB when I am really whacking them.Around the house, I got the following readings

Dining room (directly above the room I'm building the drum room in): 88 dB

Living Room: 72dB

My Sons room which is in the finished part of the basement: 86dBgreat to have those readings!!!!

The electrical panel is in a closet at the back of the room I am using for a control room. I haven't got the routes planned yet, but am planning on surface mounted boxes to cut down on the number of penetrations.

I have put some thought into running the other wiring. Planning on running PVC pipe from the control room to the live room. Not a straight run of it, but with a few bends, and maybe rubber couplers to help alleviate transmission noise thru the PVC.

Looking to cable for maybe 16 mics, 4 headphone returns, and a couple of ethernet cables, as I think if I build this right I should have terrible wi-fi coverage in this room.

its good you've got a basic idea of the high and low voltage wiring, that can be used as a baseline for the plans, and evolve as needed. you may also want to plan on an hdmi or two, and some USB/data cables, for drives and peripherals. theres a good chance your gonna want a qwrty keyboard, and screen near the drums so you can operate the DAW from either room.

The advantage you have with the true Room-in-Room, is you can carry much more drywall, both on the existing structure, and the new one. you save money by not having to use clips, and channel based systems, or Green Glue, which are good products, but charge a premium for they're benefits. the more you can stick with standard the better, from cost, convenience, familiarity, and ease of use.

the place you have to commit to is how many layers between the joists. i'd aim no fewer than three, no more than five layers. 3 is probably the golden number, since you'll gain more performance from additional layers on the isolation walls/ceiling, than in between the existing joists. but if you got the moxy, by all means, as much as you and the bays can take is good, because its wont be easy to get to later.

while your doing the bays, is a good time to solidify the planning. having the plan complete before starting the new construction is essential. its impossible to plan for the unexpected things that are gonna crop up, so plan for everything you can.

your most likely gonna want your first layer of sheathing for the iso walls/ceiling to be OSB plywood. this offers structural integrity to the walls, lowers the resonant frequency, and is forgiveness for missing s stud thru 2 inches of drywall.

Jason Morris, post: 456259, member: 51197 wrote: I'll try to draw things out more completely this week.

cool. its hard to visualize things otherwise. a basic floor plan with, with poles, and other objects of interest noted, and some dimensions, and a basic gear list, would be great for keeping everyone on the same page.

Jason Morris, post: 456259, member: 51197 wrote: That area that I was planning on using as an Air Lock.. that could absolutely just be included as additional square footage in the drum room. However, that IS the area where I had to put that problematic water main/meter. If you dont think thats gonna be an issue, I will gladly extend the drum room into that space.

totally plan on using it for something!! a bass trap, storage, or just extra sqft, the more space you can have for the drums sound the better in this case. the first studio i built was for my uncles home studio, and i just boxed out the water main (which was in the control room) with a little access door on it to get to the shutoff. theres going to be good use for that area.

kmetal, post: 456260, member: 37533 wrote: if you can somehow be

kmetal, post: 456260, member: 37533 wrote: if you can somehow be absolutely sure that cavity is sealed, then add more blow foam and cut it flush with the studs, if you add drywall on top, itll be considered one leaf. it may require you to space the wall off the foundation an extra inch or so, which isnt the worst thing.

That's pretty much what I was planning on doing. If I can't get a good seal between the drywall I install over those bays, and the foam, I will rip it out.

My buddy, who is helping me with this stuff, is a very talented carpenter. Between the two of us we will figure something out, or we will rip the foam out.

kmetal, post: 456260, member: 37533 wrote: theres a good chance your gonna want a qwrty keyboard, and screen near the drums so you can operate the DAW from either room.

I'm not sure if USB would be really useful over such lengths. I actually use my iPad for transport control of my daw when I record myself. I'm planning on connecting a wifi Access point inside the studio, connected to an ethernet cable going back to the main router.

kmetal, post: 456260, member: 37533 wrote: 3 is probably the golden number

Yep, 3 was what I was going to do

kmetal, post: 456260, member: 37533 wrote: your most likely gonna want your first layer of sheathing for the iso walls/ceiling to be OSB plywood. this offers structural integrity to the walls, lowers the resonant frequency, and is forgiveness for missing s stud thru 2 inches of drywall.

SO you think I should do a layer of 3/4" plywood, then two layers of 5/8 drywall?

kmetal, post: 456260, member: 37533 wrote: totally plan on using it for something!! a bass trap, storage, or just extra sqft, the more space you can have for the drums sound the better in this case. the first studio i built was for my uncles home studio, and i just boxed out the water main (which was in the control room) with a little access door on it to get to the shutoff. there's going to be good use for that area.

In my original 'vision' for that area as an "airlock" I was planning to treat the walls with mineral wool. maybe creating a dead space for vocals or a little amp room.

I would like to extend the drum room into that area, doing away with the air-lock idea altogether, but I am not sure how I could effectively build a wall around that water main without either making the water main and meter impossible to get to, or without hurting my isolation.

Do you have any ideas for how I would build a proper wall where that water main/meter is while still making the meter and shut off valve accessible?

Jason Morris, post: 456261, member: 51197 wrote: My buddy, who i

Jason Morris, post: 456261, member: 51197 wrote: My buddy, who is helping me with this stuff, is a very talented carpenter. Between the two of us we will figure something out

Those are the scariest words in home studio. in my mind theres nothing to figure out. a putty knife, chisel, and hammer, will have that out in ten minutes. i wouldnt give it a second thought, just keep it simple. dont mean to sound like an a$$. you can see two of my builds here http://triadrecording.com/ just so you have an idea of the type of projects ive done. im by no means a master, but ive got a good well rounded base, and learned from some really knowledgeable people. id just try and urge you to stick with the known, tried and true, whenever possible. its obviously your call, i have no attachment to the project.

Jason Morris, post: 456261, member: 51197 wrote: SO you think I should do a layer of 3/4" plywood, then two layers of 5/8 drywall?

yes. this is how Rod does most of his builds, and i believe added that detail to the 2nd ed of his book. i only have the first ed. what i wold also do upfront is consider the 'what if' three layers doesnt provide enough isolation. you have the option of more layers, or of using green glue upfront. if budget allowed, the green glue is a good bet, less dust, hauling, and hanging, but is a bit more expensive, than layers of drywall alone, and a toss up when it comes to installation. if its DIY then the GG becomes less of a price difference.

it dpends on alot of things, but i would look at it as three layers 'might' cover your needs, and it might realistically, but snare drums cut air, and peoples tolerence levels vary so, i would account for this in the provisional section of the budget.

Jason Morris, post: 456261, member: 51197 wrote: In my original 'vision' for that area as an "airlock" I was planning to treat the walls with mineral wool. maybe creating a dead space for vocals or a little amp room.

I would like to extend the drum room into that area, doing away with the air-lock idea altogether, but I am not sure how I could effectively build a wall around that water main without either making the water main and meter impossible to get to, or without hurting my isolation.

Do you have any ideas for how I would build a proper wall where that water main/meter is while still making the meter and shut off valve accessible?

those are good ideas and definate possibilities. if you build the wall around the pipe, you can put a door, or a small acessess panel there to get to the meter. as long as things are gasketed properly, and the door/panel is as massive as the wall (ie same # of layers of drywall) your all set.

kmetal, post: 456263, member: 37533 wrote: you have the option o

kmetal, post: 456263, member: 37533 wrote: you have the option of more layers, or of using green glue upfront. if budget allowed, the green glue is a good bet, less dust, hauling, and hanging, but is a bit more expensive, than layers of drywall alone, and a toss up when it comes to installation. if its DIY then the GG becomes less of a price difference.

I'm already using Green Glue as I beef up the existing structure. I'm planning on Green Glue between each layer of drywall in my build.

kmetal, post: 456263, member: 37533 wrote: those are good ideas and definate possibilities. if you build the wall around the pipe, you can put a door, or a small acessess panel there to get to the meter. as long as things are gasketed properly, and the door/panel is as massive as the wall (ie same # of layers of drywall) your all set.

Ok. Maybe I'll give that some thought and see if I can come up with something. Thanks again!

Jason Morris, post: 456264, member: 51197 wrote: I'm already usi

Jason Morris, post: 456264, member: 51197 wrote: I'm already using Green Glue as I beef up the existing structure

can you explain this a bit more? green glue is only effective in places they've tested and recommend it would be wasteful/inefficient otherwise..

Here's a quick illustration of what can be done around that pipe.

as far as isolation goes, you should be Rock Ready! im glad your

as far as isolation goes, you should be Rock Ready! im glad your realistic from the get go about your requirements, that's usually the folly of most projects. glad to help, this stuff fascinates me. Cheers!

P.s In 'The Book' in the doors and windows, or hvac section, i believe, rod does as diagram of a little door for an iso wall where they use a Thru wall air conditioner, like what you put in a window. thew same concept can be applied to anything that needs temporary access.

kmetal, post: 456265, member: 37533 wrote: can you explain this

kmetal, post: 456265, member: 37533 wrote: can you explain this a bit more? green glue is only effective in places they've tested and recommend it would be wasteful/inefficient otherwise..

I have been cutting 5/8 drywall into 14 1/2" strips to beef up the subfloor "leaf". So between my joists I have GreenGlue, drywall, GreenGlue, drywall, sealed with green glue sealant between each layer, then battened into place with 1x2. I thought that I got the idea from Rod's book, but I have read so many things on the internet, that maybe I'm conflating what I read in his book with something I read somewhere else.

At this point, the "beefing" is about 80% done, so if I did things wrong, hopefully, it is just wasn't cost effective. I'd rather lose the couple hundred bucks than all the time.

On another note, I decided to go down and see how easy it was to pull that insulation out.. Way easier than I thought. I will just go that route.

Thanks for the ideas about dealing with the pipe! I think I will do something like that too. :)

Jason Morris, post: 456268, member: 51197 wrote: I have been cut

Jason Morris, post: 456268, member: 51197 wrote: I have been cutting 5/8 drywall into 14 1/2" strips to beef up the subfloor "leaf". So between my joists I have GreenGlue, drywall, GreenGlue, drywall, sealed with green glue sealant between each layer, then battened into place with 1x2. I thought that I got the idea from Rod's book, but I have read so many things on the internet, that maybe I'm conflating what I read in his book with something I read somewhere else.

At this point, the "beefing" is about 80% done, so if I did things wrong, hopefully, it is just wasn't cost effective. I'd rather lose the couple hundred bucks than all the time.

On another note, I decided to go down and see how easy it was to pull that insulation out.. Way easier than I thought. I will just go that route.

Thanks for the ideas about dealing with the pipe! I think I will do something like that too. :)

oh ok. i dont recall seeing that in the book, perhaps it was the second edition. either way its not gonna hurt top just finish up the way you've been going. the green glue will make an improvement, certainly not make it worse. it just makes the improvement difficult to quantify. no harm no foul at this point imho. Glad to here the insulation removal looks quick.

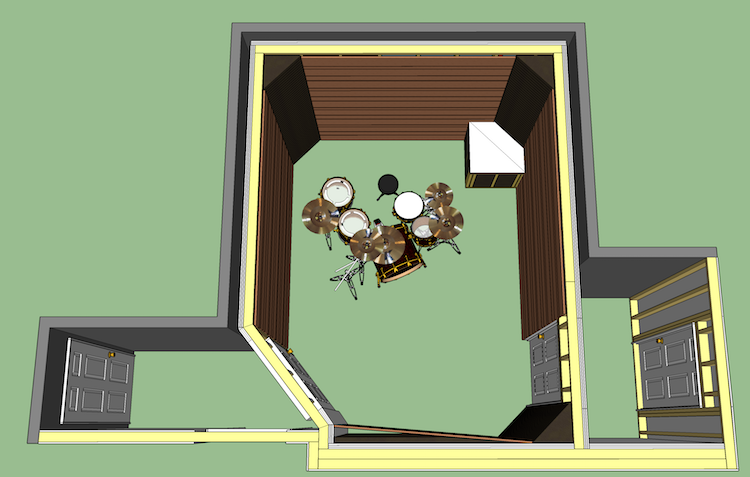

I went back and rebuilt my sketchup model, as I found a couple e

I went back and rebuilt my sketchup model, as I found a couple errors in the old one.

I'm pretty new to sketchup, and I may have gotten a little carried away with modeling my whole flippin' finished basement.. well.. about 85% of it anyway.

Here are some pics of what I have so far.

I also have the actual sketchup file if anyone is interested. Im not sure how file linking works here, but here it is.

Sorry, I should have posted this earlier.. Attached is a photo o

Sorry, I should have posted this earlier.. Attached is a photo of some obstructions in the existing ceiling joists I am going to have to deal with,

My span is going to be about 13'. I'm pretty sure that necessitates at least using 2x6's for the joists of my "inner" ceiling.

Anyone have any ideas how I can maximize my final ceiling height without having to pull back all that electrical?

The one bit of conduit I am planning on pulling back anyway, but all that romex would be a bit of a mess.

I think if I just proceed by putting the 2x6's between the existing joists, as far as I can I will end up with a ceiling height of 7' 10 1/8" from concrete to the bottom of the 3rd layer of drywall.

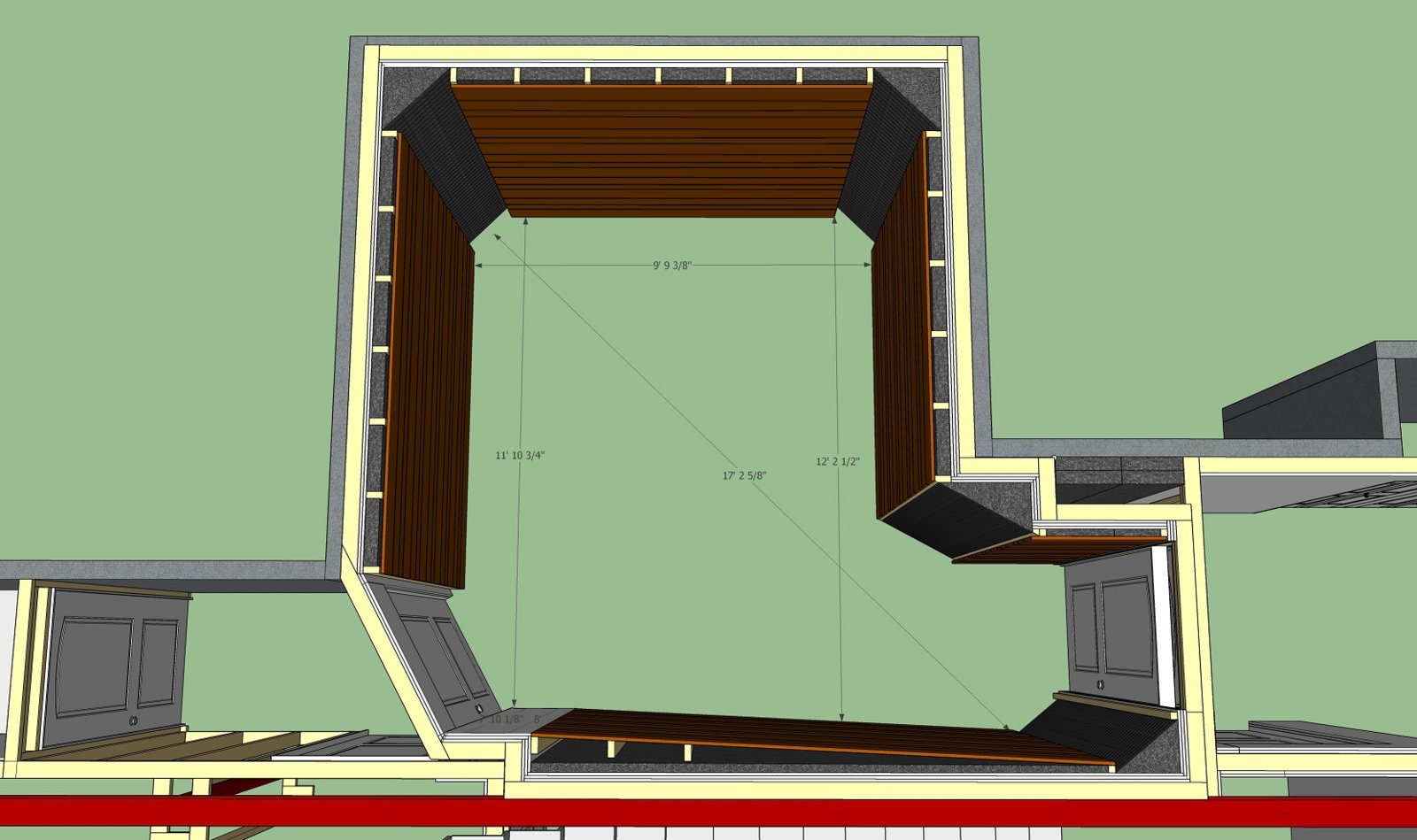

Ok, here is the layout I am thinking of going with, along with w

Ok, here is the layout I am thinking of going with, along with what I think is the way I need to build the ceiling. If I build it this way, that leaves me with a ceiling height of 7' 8 1/8".

This assumes I don't cover the ceiling in some sort of wood, and just leave it all totally absorptive. Maybe thats what I need to do in a room with ceilings this low?

I think the only other way to get more ceiling height would be to try to figure out how to do one of those "inside out" ceilings. I know people do them, but I have not been able to figure out the best way to accomplish that.

Anyway, I'd appreciate any feedback on this stuff.

Thanks

hey man, glad to see your putting real though into this. im gon

hey man, glad to see your putting real though into this. im gonna stare at the drawings (which look nice btw) for a while, and let things rattle around. i think there's a couple things that could be nudge around, to maximize the usable space. My family and I, are in the real estate/construction business, and we are under agreement for a new fixer upper, so i figure ill toss out my first impressions, but im sure ill have something more to offer, just may take me a few days.

First thing i would do is omit the closet, and build the walls close to the foundation. It gives more usable cubic footage. in reality it will probably be a bass trap (ie closet stuff with insulation) but its best inside the room, otherwise it gets into extra walls and ceilings to maintain isolation. the sump pump can be buried within some acoustic treatment, but left accessible.

beyond that, as far as the drawings, i have to play around with it and stew for a bit, but i figured id mention the bass trap thing. also, if possible, id probably get rid of that angled door, that leaves a bigger drum room, and access to the garage when nobody's looking for verb chamber/re-amping. i try to avoid doors whenever possible because they are expensive, and painstaking to install.

the way i see it is to trace the outline of the entire place with the iso walls, then a dividing partition to separate the room. as if it were one large open room, with a line across it somewhere. i try and avoid compartmentalization of the iso walls and spaces. that can generally be done in cooperation with the acoustic treatment. iso walls eat up valuable cubic footage, the bigger the room, the easier to treat it, to a point. basically i want to maximize the perimeter area, if i could describe it well.

Jason Morris, post: 456322, member: 51197 wrote: Sorry, I should have posted this earlier.. Attached is a photo of some obstructions in the existing ceiling joists I am going to have to deal with,

My span is going to be about 13'. I'm pretty sure that necessitates at least using 2x6's for the joists of my "inner" ceiling.

Anyone have any ideas how I can maximize my final ceiling height without having to pull back all that electrical?The one bit of conduit I am planning on pulling back anyway, but all that romex would be a bit of a mess.

I think if I just proceed by putting the 2x6's between the existing joists, as far as I can I will end up with a ceiling height of 7' 10 1/8" from concrete to the bottom of the 3rd layer of drywall.

giving up ceiling height is always a last resort. id rather those wires run thru the studio, than make the ceiling lower. its easy enough to move wires. you could just have them run through the ceiling treatment. the ceiling is most likely going to be dead. either with acoustic ceiling tile, or a cloud thats most of the room. id consider all ceiling/wall junctions bass traps. so bass traps around the perimeter, cloud/broadband absorption in the rest of it. ceiling reflections are useless in this context.

Jason Morris, post: 456325, member: 51197 wrote: Ok, here is the layout I am thinking of going with, along with what I think is the way I need to build the ceiling. If I build it this way, that leaves me with a ceiling height of 7' 8 1/8".

This assumes I don't cover the ceiling in some sort of wood, and just leave it all totally absorptive. Maybe thats what I need to do in a room with ceilings this low?I think the only other way to get more ceiling height would be to try to figure out how to do one of those "inside out" ceilings. I know people do them, but I have not been able to figure out the best way to accomplish that.

Anyway, I'd appreciate any feedback on this stuff.Thanks

id do it as pictured in the book as far as the isolation assembly, and do the acoustic treatment something like what i said above. the acoustic treatment ends up basically a false wall. its not a third leaf, because its not air tight, and its physically coupled to the isolation wall. its cheaper and much better looking than individual wall panels, less man hours to fabricate, and gives you a place to hide wires, and mount boxes. you almost never see the actual isolation wall of a studio. this makes the goal for the layout of the isolation walls/ceiling to keep the place as big and open as possible initially, maintaining the required decoupling.

i know treatment isnt the focus of the drawings, layout is, i just figured id mention it, as it does need to be accounted for. layout is first and foremost. its arguably most important, and surely most expensive to change after the fact. once things get zoned in on paper more, draw lines one the actual floor, and even hang tarps or blankets up where the walls would be to 'feel it'. its a bit of trial and error.

anyway man, this project is fixing to come out cool. i think theres adequate space for a nice even response in your control room, and a nice tight drum room, with a bitchin' echo chamber. i really do think this has some potential to be a good sounding, fun pair of rooms. Cheers!

kmetal, post: 456330, member: 37533 wrote: First thing i would d

kmetal, post: 456330, member: 37533 wrote: First thing i would do is omit the closet, and build the walls close to the foundation. It gives more usable cubic footage. in reality it will probably be a bass trap (ie closet stuff with insulation) but its best inside the room, otherwise it gets into extra walls and ceilings to maintain isolation. the sump pump can be buried within some acoustic treatment, but left accessible.

Hey man! Thanks for chiming in.

I should have been more clear.. everything EXCEPT the drum room is pretty much built already. The basement is enormous and has already been finished out to the hilt, with a living room, kitchen, bedroom etc..

I have been given a finished area that is becoming my "control room", and the unfinished area that is going to be my drum room. In the drum room, I have free reign. In the control room I have mostly free reign, but I'm not sure I could get her to go for tearing the closet out. Also, because that closet is where the Sump pump and radon mitigation system are located, I don't know how much usable space I would get out of tearing it out... Except for that wall at the back of my control room would disappear, making the room less square.

quick question- is there any ceiling bridging? like a silod 2x?

quick question- is there any ceiling bridging? like a silod 2x? framing or 1x3's in and x like/diagnoal, in the bays as suppoports for the ceiling? in other words, if the wires and duct werent there, could trhe 2x6's go right up as high as the drywall in the bay (minus an inch?)

Jason Morris, post: 456331, member: 51197 wrote: Hey man! Thanks

Jason Morris, post: 456331, member: 51197 wrote: Hey man! Thanks for chiming in.

I should have been more clear.. everything EXCEPT the drum room is pretty much built already. The basement is enormous and has already been finished out to the hilt, with a living room, kitchen, bedroom etc..

I have been given a finished area that is becoming my "control room", and the unfinished area that is going to be my drum room. In the drum room, I have free reign. In the control room I have mostly free reign, but I'm not sure I could get her to go for tearing the closet out. Also, because that closet is where the Sump pump and radon mitigation system are located, I don't know how much usable space I would get out of tearing it out... Except for that wall at the back of my control room would disappear, making the room less square.

well i hear you about the closet. as long as its full (which shouldnt be a problem) it is a bass trap. as far as usable space gained, if im seeing it right, the wall blocking off the sump pump is 4' or so from the foundation? if so, thats a wonderful amount of space gained for trapping. you could really start to hear that fundamental in the kick drum. even if you just stuffed the space loosely with insulation, its a bass trap. basically any space connected to the room like a closet, is a bass trap as soon as its loosely packed.

kmetal, post: 456330, member: 37533 wrote: also, if possible, id

kmetal, post: 456330, member: 37533 wrote: also, if possible, id probably get rid of that angled door, that leaves a bigger drum room, and access to the garage when nobody's looking for verb chamber/re-amping.

The only issue with that is that hallway is existing structure, the other side of which is finished out. It's one of the rooms my oldest son occupies. I can't knock the wall out, and building a double wall in the existing space would likely make the hallway too narrow. I put the door there because the left (north) side of that drum room's wall terminates right at the door that leads to the finished part of the basement. If you zoon in on the drawing, you can barely see the door is centered right over that corner. My angled door was an attempt to deal with that.

kmetal, post: 456332, member: 37533 wrote: quick question- is there any ceiling bridging? like a silod 2x? framing or 1x3's in and x like/diagnoal, in the bays as suppoports for the ceiling? in other words, if the wires and duct werent there, could trhe 2x6's go right up as high as the drywall in the bay (minus an inch?)

There WAS some x bracing there, which probably needs to go back in now that I have done the beefing up of the sub-floor.

kmetal, post: 456333, member: 37533 wrote: well i hear you about

kmetal, post: 456333, member: 37533 wrote: well i hear you about the closet. as long as its full (which shouldnt be a problem) it is a bass trap. as far as usable space gained, if im seeing it right, the wall blocking off the sump pump is 4' or so from the foundation? if so, thats a wonderful amount of space gained for trapping. you could really start to hear that fundamental in the kick drum. even if you just stuffed the space loosely with insulation, its a bass trap

That's not a bad idea. I could probably turn that closet into some bass trapping even if I can't get the wifey to let me tear it all down.

So what happens if I fill large portions of that closet with mineral wool? Does it basically become a big panel trap?

Jason Morris, post: 456334, member: 51197 wrote: The only issue

Jason Morris, post: 456334, member: 51197 wrote: The only issue with that is that hallway is existing structure, the other side of which is finished out. It's one of the rooms my oldest son occupies. I can't knock the wall out, and building a double wall in the existing space would likely make the hallway too narrow. I put the door there because the left (north) side of that drum room's wall terminates right at the door that leads to the finished part of the basement. If you zoon in on the drawing, you can barely see the door is centered right over that corner. My angled door was an attempt to deal with that.

There WAS some x bracing there, which probably needs to go back in now that I have done the beefing up of the sub-floor.

cool, ill take a closer look at the drawings tonight. the X bracing should go back. do the wires run below the bracing? ie between floor and bracing? ive got some pics of what it looks like w x bracing under the drywall. ill post when i come across them. the cool thing is thats how its illustrated in the book.

kmetal, post: 456336, member: 37533 wrote: do the wires run belo

kmetal, post: 456336, member: 37533 wrote: do the wires run below the bracing? ie between floor and bracing?

Yep. And the wiring runs thru the joists about 1 1/2" from the bottom of the joists.

I have been thinking on doing one of John Sayers "inside-out" ceilings. If I did that, I think I would have an "acoustic ceiling" of about 8' 2", and about 7'10" of headroom with 3 1/2" of mineral wool covered by cloth treating the ceiling.

Jason Morris, post: 456335, member: 51197 wrote: That's not a ba

Jason Morris, post: 456335, member: 51197 wrote: That's not a bad idea. I could probably turn that closet into some bass trapping even if I can't get the wifey to let me tear it all down.

So what happens if I fill large portions of that closet with mineral wool? Does it basically become a big panel trap?

yeah. it would resemble the drawings in the book of a corner trap, just square.

so youd take your mineral wool, straddle all the corners, stuff fluffy Insul behind those, then on the wall have a few mineral wool panels spaced off the wall, with some insualton behind it.

on the front face, you could do a mineral wool panel with fabric, a door (partially opened, or with regular typical closet door gaps), you could have pegboard, or slats tuned to the room mode, (somewhere around 70-80hz.)

Jason Morris, post: 456337, member: 51197 wrote: Yep. And the wi

Jason Morris, post: 456337, member: 51197 wrote: Yep. And the wiring runs thru the joists about 1 1/2" from the bottom of the joists.

I have been thinking on doing one of John Sayers "inside-out" ceilings. If I did that, I think I would have an "acoustic ceiling" of about 8' 2", and about 7'10" of headroom with 3 1/2" of mineral wool covered by cloth treating the ceiling.

to me its easier to snip the wires at each end, make put a junction box there, and just add some wire, so the runs go somewhere else, even thru the studio hidden above the cloud. essentially just extending the wires so they cross somewhere else.

how do you air seal an inside out ceiling? how do you get all the drywall on top? those have only ever made sense in my mind, in spaces where theres crawl spaces ect. ive spent hours on Sayers site looking at each build, i save most of them in my photos, for reference, i dont recall seeing it done like that in a residential situation.

acoustic tile, foam, or cloud panels are far simpler for treatment, and making a few romex connections is easy peasy. you can run your studio wires at the same time. i wouldnt doubt there's mods that will need to be made at the panel, as far as grounding, and balancing the load.

by all means do what you want. i just dont have any experience with inside out type builds. i just make a 'false' or 'acoustic' wall as i refer to it, in front of the isolation wall. which give me the cheapest build, and offers the most control acoustically, and aesthetically. John Sayers is world class, so i don;t imply his method isn't good, just that i havent used it.

Ps, even if the closet had clothing hanging in it, functioning a

Ps, even if the closet had clothing hanging in it, functioning as a closet, its a bass trap. like a sponge for sound.

sorry if i sound obsessed with bass traps, it the main thing that needs to be accounted for acoustically. my life changed when i could just mix to the speakers, knowing there's no surprises in the car. the only surprise was 'hey this doesnt need tweaks!!!'

These are some snapshots from my iphone, of the home theater des

These are some snapshots from my iphone, of the home theater design/build i did. the insulation hadn't been put back in yet. the last pic also shows Risc-1/hat channel, and iso wall, which was temporarily screwed in. like a lego set for grown ups.

i also have some sketches of the traps, which were plentiful, but im not sure they'd make a ton of sense. i based them off rods book, so its mostly about location.

Hi guys... I'm just gonna jump in real quick here with a questio

Hi guys... I'm just gonna jump in real quick here with a question that may be pertinent. If it's not, I apologize...

How old is your house/structure?

The reason I ask...

It's best to know what you are removing before you start removing it...

I'm just giving you a heads-up in case there may be asbestos in there somewhere. (??)

Lots of older houses have it, usually around duct work; and while it usually poses no threat if it's not touched, it can be a very real respiratory hazard if you start ripping it off of things and the fibers start floating around.

Okay, I'm done. (Sorry Kyle... didn't mean to interrupt your very cool advice)

I Just don't want anyone getting hurt or sick in case this hasn't yet been discussed.

-d.

kmetal, post: 456339, member: 37533 wrote: how do you air seal a

kmetal, post: 456339, member: 37533 wrote: how do you air seal an inside out ceiling? how do you get all the drywall on top? those have only ever made sense in my mind, in spaces where theres crawl spaces ect. ive spent hours on Sayers site looking at each build, i save most of them in my photos, for reference, i dont recall seeing it done like that in a residential situation.

It didn't make a lot of sense to me at first either. Stumbling across this post helped a lot:

http://www.johnlsayers.com/phpBB2/viewtopic.php?f=2&t=21165&p=143149&hilit=rim+board#p143149

After reading that, along with other stuff on Johns site, I think I have a pretty good idea of how to do it. Still not 100% sold on it yet, but it's being considered.

kmetal, post: 456342, member: 37533 wrote: also, as far as your control room, am i right in thinking your not doing any sort of construction to it, just treating it? noise from the CR isnt a problem ie mixing at night? just trying to get a feel for the whole scope of things.

I can probably get away with some stuff on the control room side of the build. At first, she was not thrilled with me doing anything other than wife-approved acoustic treatments. She has since come around to understanding that I may need to do more than that. I will likely need to remove some drywall in that room when I run cables.

When I do, I will likely remove a lot more of it than I need so that I can beef up the ceiling and the opposite wall with more 5/8drywall "between the joists".

And then I'll likely cover it all back up with another 2 layers of drywall.

I don't think double wall construction is going to be happening for the control room though. I think that would be a bridge to far for her.

But I WILL be treating the crap out of it.

MY isolation needs for that room aren't quite what they are for the drum room. To be honest, while I am more concerned with making my drum room quieter for everyone ELSE in the house, I am mainly concerned with making the control room quieter for MYSELF. Blocking out the noise of our kids playing Fortnite or her goofy little dog barking at squirrels.

DonnyThompson, post: 456343, member: 46114 wrote: Hi guys... I'm just gonna jump in real quick here with a question that may be pertinent. If it's not, I apologize...

How old is your house/structure?

The reason I ask...

It's best to know what you are removing before you start removing it...

I'm just giving you a heads-up in case there may be asbestos in there somewhere. (??)

Hey Donny! Thanks for chiming in as well. I do understand about asbestos, and I don't think it's a problem. The house was built in 1997.

The house I ALMOST bought.. that was riddled with asbestos. Thankfully someone swiped the house out from under me two weeks before closing. Still stings to think about, but the truth is they probably did me a favor. I wouldn't be building a drum room in that place, that's for sure.

kmetal, post: 456340, member: 37533 wrote: sorry if i sound obse

kmetal, post: 456340, member: 37533 wrote: sorry if i sound obsessed with bass traps, it the main thing that needs to be accounted for acoustically. my life changed when i could just mix to the speakers, knowing there's no surprises in the car. the only surprise was 'hey this doesnt need tweaks!!!'

It's quite alright, and your input is much appreciated.

I have built traps before. Several types. Back wall absorber, corner traps, superchunks, Helmholtz slot traps, and a couple kinds of panel traps.

I actually built a small studio probably 12 years ago in the basement of my last home. However, I have forgotten a great deal of what I learned.. I learned it for that build then never did anything with it again.

Also, I know now that I did a lot of things WRONG, and I really want to try to get good isolation with this build.

I think I mentioned before that while MY kids were raised to fall asleep listening to me play drums, my new wife's kids were NOT.

And one of them, in particular, has a very strong negative reaction when I play. They wifey tells me not to worry about it so much, but it's tough to play when you know you are driving someone out of their mind with anxiety. Tough to look at the abject horror on their face when you say "I think I'm gonna go play drums for a bit!"

:D

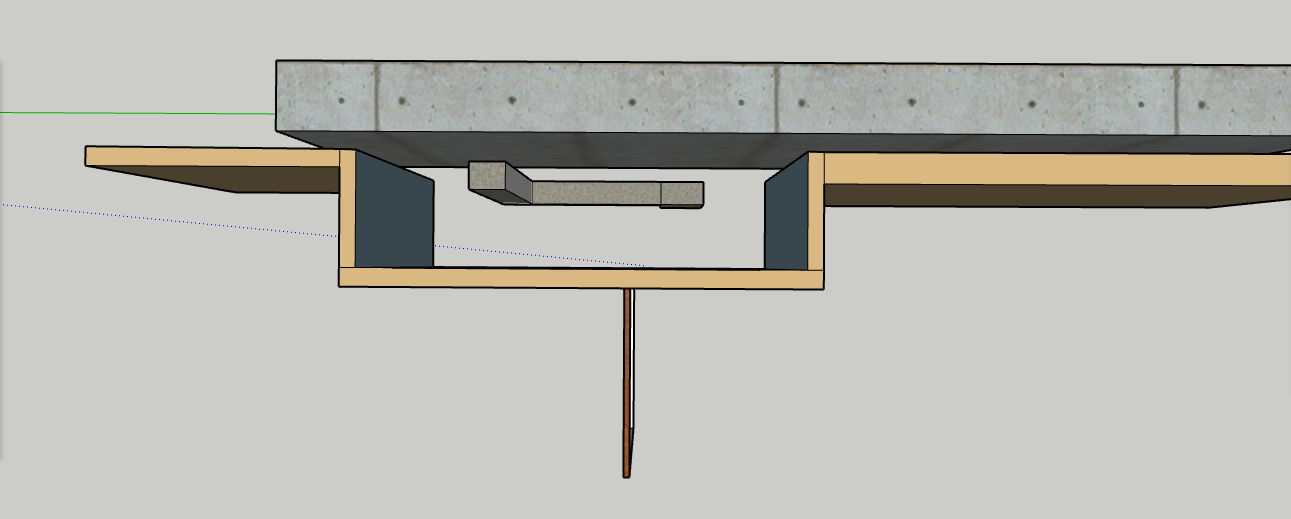

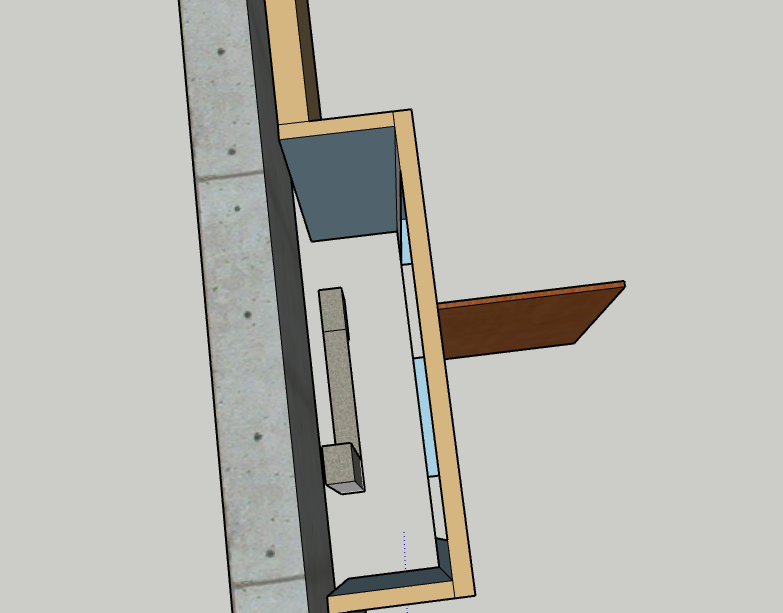

This is a quick drawing of an "inside out" ceiling, at least as

This is a quick drawing of an "inside out" ceiling, at least as I understand it.

You have the existing joists, on top, with new joists about 1/2" below them. And then you build these ceiling "modules", which are 2x4 frames, with 5/8 OSB, then two layers of 5/8 Drywall top op of them. I'd use green glue between all the layers, and seal the modules up with acoustic caulk.

You can then insert the modules into the "new" ceiling joists, screw them into place, fill any cracks between the 2x4 modules with backer rod, and acoustic caulk.

Once all the modules are in place, you could add mineral wool inside the frames to treat the ceiling, then cover the whole thing with whatever acoustic fabric you want.

I'm pretty sure the design allows for higher "acoustic" ceilings, even if the headroom is about the same, and (I think) it would provide some diffusion.

In my drawing, I have 2x8's about halfway down the length of the new joists so that there are multiple pockets for these modules. I don't think that is strictly necessary.

My understanding is that you can create these modules whatever size you determine is manageable, so you could create one module for the entire joist span if you have a life, or enough friends to put the module into place after it is built.

Oh, even though you can't tell from the drawing, the modules are pushed all the way to the top so that the top layer of drywall is even with the top of the "new" joists.. 1/2" away from the existing joists.

Jason Morris, post: 456345, member: 51197 wrote: It's quite alri

Jason Morris, post: 456345, member: 51197 wrote: It's quite alright, and your input is much appreciated.

I have built traps before. Several types. Back wall absorber, corner traps, superchunks, Helmholtz slot traps, and a couple kinds of panel traps.

I actually built a small studio probably 12 years ago in the basement of my last home. However, I have forgotten a great deal of what I learned.. I learned it for that build then never did anything with it again.

Also, I know now that I did a lot of things WRONG, and I really want to try to get good isolation with this build.

I think I mentioned before that while MY kids were raised to fall asleep listening to me play drums, my new wife's kids were NOT.

And one of them, in particular, has a very strong negative reaction when I play. They wifey tells me not to worry about it so much, but it's tough to play when you know you are driving someone out of their mind with anxiety. Tough to look at the abject horror on their face when you say "I think I'm gonna go play drums for a bit!":D

Is the kid with the anxiety issues old enough to participate with you on the planning and construction of the drum room? I ask because even as a young person, involving them in some way with this process on the learning and planning side will also clandestinely empower them - it's like therapy without therapy - plus it will provide some bonding time/experience between you and them with the drums and the drum room suddenly being nexus you have in common - not something this new dad dude is inflicting on them....

Hi Jason, welcome to RO I did essentially the same thing a few

Hi Jason, welcome to RO

I did essentially the same thing a few years back. Doing a room in a room and it paid off greatly.

I did the setup in the image below but I used a layer of Carton Fibre Naturel "TENTEST" to seal up the rockwool and avoid particules in the air.

I bought Safe and sound doors and used the 2 glass of a patio door as a window to see the artists.

The air gap all around the room is a good isolation and having 2 sound isolated walls facing each other helped too.

As for now, only low frequencies bleeds from my room but it's a very low amount. Not enought to bother my neighbors (I'm in a duplex)

Also I added bass traps and accoustic pannel inside the room because mine is very small and had Flutter echo and bad reverb...