Hi!

I have been slowly working on building out a new room in my basement for practicing/recording drums.

It's been a slow process, that has thus far involved removing water heaters, and breaking up the concrete floor to re-route the water main so that I have a relatively unobstructed floor space to work with.

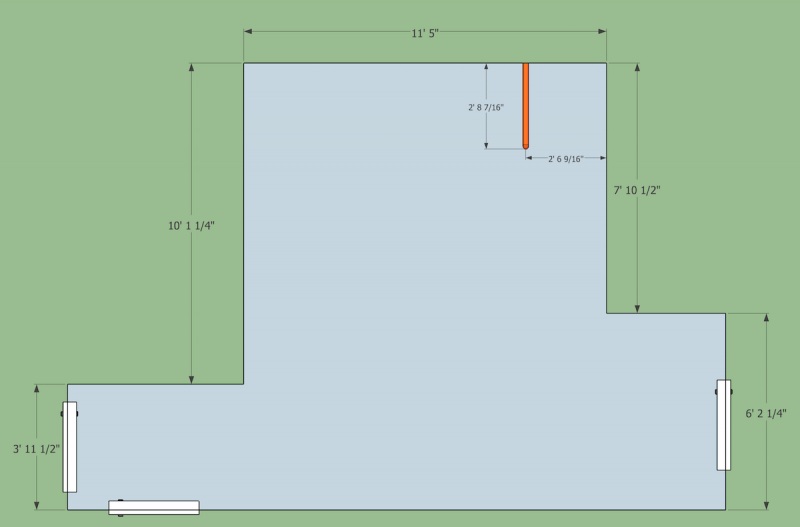

I have about 8' 4" from floor to the bottom of the ceiling joists, and about 11 1/2' x 14' of space to work with.

As a side note, the rest of the basement is finished, and the lovely wife isn't wild about me tearing that stuff apart as I do my build.

I have started beefing up the existing subfloor above my space using 'rods method' of adding two layers of 5/8 drywall between the joists, with green glue, and then battening them into place with 1x2.

My plan is to build the 'room in a room' and have a new "inner ceiling" supported by the new framing I build.

In the picture attached you can see what I have going on thus far.

My questions are:

In the attached picture, you can see a space (labeled A). On the other side of that is the brick veneer of my home.

If I seal that area up with drywall and acoustic sealant, am I essentially creating a small 3-leaf system once I have my drum rooms walls built? Should I fill that cavity with layers of drywall? just insulation? Or is it such a small space that I shouldn't be fretting about three leaves?

Also, Above this ceiling is our 'formal' dining room (not used much).

In the space labeled "B" you can see the ductwork feeding the vents in that dining room.

Keeping in mind that I AM going to be building that decoupled "inner" ceiling, what should I do about that duct and vent feeding the dining room?

Comments

Just dropping a line to reiterate that I HATE doing these doors/

Just dropping a line to reiterate that I HATE doing these doors/seals.

I got the first set of seals on the two doors.

things don't seem to be working as well as I would like them to though.

I have done the flashlight (in my case a work light) trick.. I don't see any light around the seals.. EXCEPT the corners.

I have not figured out a good way to seal up the corners really well.. where one seal butts up against another there is always a bit of a gap.

If they overlap, the door doesn't close right.

Any tricks for getting the corners right?

also, how tight should the door be compressing into the seals?

The doors are only just laying across the trunk rubber. the trunk rubber is too dense to compress much from just the weight of the door and closer.

I ahve not placed the second set of seals, but right now the doors do not seem to be performing very well.

I know things are not "done" yet, but I did some preliminary testing and was pretty disappointed.

One of the challenges in studio construction seems to be that you can't really test the isolation until ALL the components are in place.

:/

Doors are the worst. The upside is once set correctly, they stay

Doors are the worst. The upside is once set correctly, they stay put for quite some time. It took me until door #5 until i could install them methodically, and less painfully. Still they take trial and error or just plain good luck.

I think part of the reason for the redundant seals is the likelyhood of imperfection in one seal.

Jason Morris, post: 461372, member: 51197 wrote: Any tricks for getting the corners right?

I cut the corners at 45 degree angles. When the door shuts the corners compress into each other and create the seal.

You could also do this with a butt joint, where the seal corners meet at a right angle. You cut one seal straight to meet up against the door jamb, and you the the other seal so its contour is meets up with the other seal flush.

Difficult to describe. I can try again if this wasnt clear. If my life was not in shambles id have the pics available of the seal details.

I also used caulking in the seal corners, to verify a continuous seal. Non-hardening silicone, or butyl caulking only. No acryllic.

Either way, you want the seals to make slight contact with each other at the corners. Not enough to bunch up too much, but enough so there is no gap.

Also the seals might be fine, you may just need to bend the door stop into place so it contacts the door. Do this with a cabinet clamp. Its why i use screws for the jambs. The invetible trial and error.

Jason Morris, post: 461372, member: 51197 wrote: also, how tight should the door be compressing into the seals?

Just enough to make contact. "A little bit". Maybe a 1/16 to 1/8th inch. More is fine as long as the door shuts. Prime goal is full contact.

I will mention, i ordered type k on two different occasions, one was quite squishy and easier to work with, than the firmer one. They were both type k, but not identical.

When i set the doors, i do it so a gentle push on the open door swings the door shut and lactched. The first two i did require a bit more effort and youve got to pull them shut with some force. Not convenient, but they do seal.

Jason Morris, post: 461372, member: 51197 wrote: One of the challenges in studio construction seems to be that you can't really test the isolation until ALL the components are in place.

Yes sir. This is the reasoning behind using lab tested assemblies.

Its difficult for people who haven't suffered thru a build like you have, to understand the studio room a complete system, like a car or anything else. It only works properly in whole.

You may need a second set of seals. These can be standard ribbed weatherstrip, type k, or magnetic weatherstrip. The magnetic is cool because it seals even if the door doesn't shut perfectly agaisnt the type k, its got flex and give, like the weatherstrip on a refrigerator. Ive not used the magnetic stuff yet, but its in rods book for good reason.

Is the rubber installed with the thinner side attached to the jamb?

Pics could help me verify what the issues are.

I am attaching some pics of where I am at with the seals. I have

I am attaching some pics of where I am at with the seals. I have removed and reinstalled them numerous times. I'm about to tack in the last set of stops now.

Between both sets of seals, things seem to be sealed up. I can't see any light.

In fact, I daresay that when the light is off, it is the darkest room I have ever been in in my life.

I'm still not 100% wild about the doors though. I may have to run with them for now and rip/replace the seals at a later date.

I probably have 8-10 hours of fiddling into these seals right now. :/

Also, I still have the door/seals to do for access to the water main. That is the last link in the isolation game.

I have done a little testing, despite the gaping hole. I sure do hope there is a dramatic difference once that hole has a door in it.

My testing has shown pretty terrible low-frequency isolation. I guess its to be expected when there is a 2'x3' hole in one wall.

So, as I mentioned, I did some testing, even though that access

So, as I mentioned, I did some testing, even though that access hatch for the water main is not done, and I found the results pretty disappointing.

Now I am wracking my brain trying to think of things I may have done wrong/poorly along the way.

The only thing I did that I am a little worried about is this: For the inside out wall assembly, it still calls for insulation between the inner and outer leaf (in that 4" air gap space).

All of my insulation had kraft paper on it, and rather than ripping it off, I applied the insulation kraft-paper side to the drywall with spray adhesive and a few staples at the very top in keep the insulation in place.

I know that kraft paper is generally recommended to be removed, but I thought I read that it can be applied with the paper facing the drywall side to avoid creating a mini .3rd leaf.

I am hoping this is not the thing short-circuiting my whole assembly. Not sure what I could do about it at this point actually.

Jason Morris, post: 461393, member: 51197 wrote: I'm still not 1

Jason Morris, post: 461393, member: 51197 wrote: I'm still not 100% wild about the doors though. I may have to run with them for now and rip/replace the seals at a later date.

The seals look good to me overall. The one concern i have is on pic #3327, the bottom left section. The seals dont appear to meet. That is an issue.

You can also put silicone (non hardening) caulking at any seems in the wood work. I caulk everything that is a seem, including the finish moulding. You can use is at corner junctions of the seals too. I use clear caulking for all this.

Jason Morris, post: 461393, member: 51197 wrote: I probably have 8-10 hours of fiddling into these seals right now. :/

Sounds about right. Ive put 35 hours into a single door before. At least you've only got to get it right once.

Jason Morris, post: 461394, member: 51197 wrote: So, as I mentioned, I did some testing, even though that access hatch for the water main is not done, and I found the results pretty disappointing.

Now I am wracking my brain trying to think of things I may have done wrong/poorly along the way.

The only thing I did that I am a little worried about is this: For the inside out wall assembly, it still calls for insulation between the inner and outer leaf (in that 4" air gap space).

All of my insulation had kraft paper on it, and rather than ripping it off, I applied the insulation kraft-paper side to the drywall with spray adhesive and a few staples at the very top in keep the insulation in place.I know that kraft paper is generally recommended to be removed, but I thought I read that it can be applied with the paper facing the drywall side to avoid creating a mini .3rd leaf.

I am hoping this is not the thing short-circuiting my whole assembly. Not sure what I could do about it at this point actually.

Im not completely well versed in inside out methods. I have left the kraft paper in wall frames in any builds ive done, installed in a standard fashion. Its there as a vapour barrier, and i think possibly a fire code thing too. The kraft paper itself will not make or break an assembly.

That said, my concern is the non-standard installation, mainly the use of the adhesive. Adhesives can affect the vibration and transmission characteristics negatively. Its why we dont use caulking between drywall layers, which would simplify installation. It restricts the sheets' ability to to vibrate independently of each other, forming a rigid connection between the two. Its what makes green glue special, it doesnt do that.

That said, i wouldn't expect the kraft paper or installation method to be a significant culprit based on what i know. I could be wrong, and i reccomend you check with Stewart, or other pro well versed in inside out methods.

Areas of concern for me-

The seal integrity between the door jamb, and opening in the wall. Rod details it in the book. I spent alot of effort with the backer rod and caulking sealing the jamb. I remember using quite a few tubes of silicone to seal the gap.

The exposed joists in the inside out method. I expressed concern about this a while back. Not being an expert in inside out, i was concerned the the joists themselves should be "wrapped" in drywal and seemed/sealed 'properly'. My concern is credited to the section in the book where Rod states the "joists themselves are the weak point in isolation" (not a verbatim quote, doing it from memory) when describing the existing ceiling with mass added to the bays. This to my mind and eyes resembles inside out construction. Now since the joists arent touching the existing assembly in your case, then it comes down to if the joists are air tight, and as massive as the drywall. I would inspect for air gaps.

----

Also, did you add mass to the door? Does the mass = the wall mass?

Also, you may need to add a latch to the door to keep it firmly shut. The door closure unit is designed primarily to close the door at a slow, safe rate, to avoid accidents. (My uncle severed his finger tips because of an unsafe massive steel commercial door at his job.) The closure may or may not also keep the door shut firmly. Its a safety precaution first and foremost.

A deadbolt, or a ball and socket catch can be used to keep the door shut. Ball and socket is something i discovered during the Normandy build. I previously used standard knobs or deadbolts.

https://www.lowes.com/pl/Ball-catches-Door-hardware-Hardware/4294395585

------

I would not be surprised to see a healthy increase in isolation when the water meter hole is plugged up. Therefore i wouldnt get too worried just yet.

I would still verify all possible gaps are sealed, and that the kraft paper is negligible.

Doors suck.

kmetal, post: 461397, member: 37533 wrote: The one concern i hav

kmetal, post: 461397, member: 37533 wrote: The one concern i have is on pic #3327, the bottom left section. The seals dont appear to meet. That is an issue.

Yeah you are correct. I will caulk the. corners up and see if that improves things. IU am trying to view these as "Doors 1.0".. I may have to break down and rip and replace the seals at some point.

Maybe doors 2.0 will be better.

kmetal, post: 461397, member: 37533 wrote: Sounds about right. Ive put 35 hours into a single door before. At least you've only got to get it right once.

Yeah when I was complaining to my lovely wife about the 8-10 hours I put into these seals she laughed and said it was about twice that. I did the math and she was right. (as usual)

kmetal, post: 461397, member: 37533 wrote: I have left the kraft paper in wall frames in any builds ive done, installed in a standard fashion. Its there as a vapour barrier, and i think possibly a fire code thing too. The kraft paper itself will not make or break an assembly.

That is a pretty big relief honestly. I really tried to stick. to what I have read are best practices, but when it came time to add the insulation I was kinda scratching my head. My buddy and I came up with this method and I did a quick search to see if Kraft paper touching. the drywall was a problem. I thought I remembered someone saying basically the same thing you said, but honestly I have so many tidbits of knowledge swirling around in my head sometimes I lose track of what I really know and what I only THINK I know.

kmetal, post: 461397, member: 37533 wrote: Its why we dont use caulking between drywall layers, which would simplify installation.

I'm not sure what you mean about this one.. I caulked the gaps between each drywall layer, as I thought I had read I should do in Rod's book? Do you mean we don't glue one layer of drywall to another with construction adhesive? Cause that I did NOT do. I DID use green glue. Not sure that was worth the expense. Probably won't use it again in the future.

kmetal, post: 461397, member: 37533 wrote: The exposed joists in the inside out method. I expressed concern about this a while back. Not being an expert in inside out, i was concerned the the joists themselves should be "wrapped" in drywal and seemed/sealed 'properly'.

Yeah, I know you had mentioned that, and I don't doubt your knowledge, and greatly appreciate the help you have given me. But I am also pretty confident in Stewart & Johns knowledge level, and I know Stewart does pretty much all of his builds that way. I am adding a pic of the ceiling joists/modules so you can see what I have going on.

kmetal, post: 461397, member: 37533 wrote: Also, did you add mass to the door? Does the mass = the wall mass?

I have TWO standard 1 1/2 solid core door slabs with 3/4" MDF green-glued and screwed to it.

kmetal, post: 461397, member: 37533 wrote: I would not be surprised to see a healthy increase in isolation when the water meter hole is plugged up. Therefore i wouldnt get too worried just yet.

Thats a relief. I know it isn't really possible to test this stuff accurately until its done, but when you have been working at it for like a. year and a half, its. hard to resist sometimes. :D

On. another note, I know you mentioned your life being in turmoil right now. I hope its nothing serious, and I hope things calm down soon for you.

Thanks again for the encouragement and guidance as I go thru this build!

Jason Morris, post: 461398, member: 51197 wrote: Yeah you are co

Jason Morris, post: 461398, member: 51197 wrote: Yeah you are correct. I will caulk the. corners up and see if that improves things. IU am trying to view these as "Doors 1.0".. I may have to break down and rip and replace the seals at some point.

Maybe doors 2.0 will be better.

You could also try and attach a little piece of type k, if the gap is big enough.

Jason Morris, post: 461398, member: 51197 wrote: Do you mean we don't glue one layer of drywall to another with construction adhesive?

Yeah thats what i meant. Glad you didn't do it.

Jason Morris, post: 461398, member: 51197 wrote: But I am also pretty confident in Stewart & Johns knowledge level,

Me too, while i can hang in a conversation with anyone at this point, i wouldnt put myself up at their level. Especially in the inside out dept. I trust their words. I have seen very knowledgeable people make mistakes, or unknowingly spread mis information, but nobody is perfect. By know john and stewart have their methods down to a science.

I wish that there was some lab data on the inside out method, for reference.

Your modules look very well sealed.

Jason Morris, post: 461398, member: 51197 wrote: I have TWO standard 1 1/2 solid core door slabs with 3/4" MDF green-glued and screwed to it.

Sounds well done. I haven't calculated the mass vs your walls, but thats a hefty door either way.

Jason Morris, post: 461398, member: 51197 wrote: Thats a relief. I know it isn't really possible to test this stuff accurately until its done, but when you have been working at it for like a. year and a half, its. hard to resist sometimes. :D

Oh for sure. I remember having an ipod hooked directly to the power amp and speakers in the empty control room at Normandy. Also i remember recording acoustic guitar in the untreated wave cave live room and the feeling of joy.

Jason Morris, post: 461398, member: 51197 wrote: On. another note, I know you mentioned your life being in turmoil right now. I hope its nothing serious, and I hope things calm down soon for you.

Thanks again for the encouragement and guidance as I go thru this build!

Thanks for the kind wishes. Starting from scratch is difficult, but there is some good stuff brewing over the horizon.

Glad i can be useful, i always respect anyone willing to do it properly. Cheers man!

kmetal, post: 461397, member: 37533 wrote: The exposed joists in

kmetal, post: 461397, member: 37533 wrote: The exposed joists in the inside out method. I expressed concern about this a while back. Not being an expert in inside out, i was concerned the the joists themselves should be "wrapped" in drywal and seemed/sealed 'properly'

I'm not trying to belabor the point, but while I was searching for information about the best type of insulation to use on the inside of my studio, I came across this post by Stewart:

" Even though wood is a bit less dense than drywall, studs are much thicker, and serve just fine to keep the surface density of the wall high enough. At an inch and a half thick, a stud is about the same surface density as two layers of 5/8" drywall."

Jason Morris, post: 461406, member: 51197 wrote: I'm not trying

Jason Morris, post: 461406, member: 51197 wrote: I'm not trying to belabor the point, but while I was searching for information about the best type of insulation to use on the inside of my studio, I came across this post by Stewart:

" Even though wood is a bit less dense than drywall, studs are much thicker, and serve just fine to keep the surface density of the wall high enough. At an inch and a half thick, a stud is about the same surface density as two layers of 5/8" drywall."

This is excellent info. Im glad you posted it.

OK! I got my hatch built. I also am like 99% sure I know where I

OK! I got my hatch built.

I also am like 99% sure I know where I am losing low end isolation.

It's coming from my silencer box. I have one set of silencers (for exhaust) built and installed and very well sealed up.

They were made out of two layers of 5/8 plywood and have i think 4 baffles inside them.

When the AC runs in the house I can hear the very low frequency rumble in my room, and it is clearly louder coming from the silencer box.

I have a silencer on the inner leaf connected to a silencer on the outer leaf with sorbothane rubber.

Maybe a video would be a better way of explaining what I have going on..

As an added bonus you get to hear my weird voice!

Oh, I found some photos that might be helpful as well... One is

Oh, I found some photos that might be helpful as well...

One is the silencer being built, the other is the silencer mounted in the wall before it was sealed up with drywall.

Edit: just realized the photo of the silencer being built is the OUTER leaf silencer, while the mounted silencer is the INNER leaf silencer.

Let me preface that hvac is the area of least knowledge for me.

Let me preface that hvac is the area of least knowledge for me. I know the basics, but have not installed a ducted system ever. Ive done thru wall ac's, mini split systems. The only ducted system i dealt with was already installed at Normandy, and there wasn't much to do with it.

I have a couple guesses. I think its either structural coupling, or the silencer is acting as a helmholtz resonator wisking air at a certian frequency. It could also be that the air flow is too fast, ideally its big ducts, and slow moving air. First 5,000 questions. I may also add that this next week or two is looking hectic for me so i will do my best to check in as often as possible. It could also be bleed if there is not double walls on the walls which dont have the concrete behind it.

How did you test the sound?

What frequency is the low noise, is it a fairly sharp peak or a wide one?

What type of hvac is that?

What type of ducting, hard or soft?

What size is the ducting?

What is the ducting attached to, and how?

Is the ducting and other hvac all attach to existing structure or new room?

Is the low end from the the hvac or is it bleed from drums out of the room?

Is the hvac connected to the rest of the house or studio only?

Is there a double wall on the door side?

In the second picture, is the silencer mounted to the existing structure or new room?

At the point of the inlet, the wall penetration, is the new wall touching the inlet?

What is making you think the issue is silencer box related?

Is there any known low frequency issues related to inside out methods?

Did any pro help with the design and implementation of the silen

Did any pro help with the design and implementation of the silencer and ducting and hvac blower or overall design of the system.

I Also saw a couple of structural things, which could be improved on, but are unrelated to the hvac. Im not sure if you care to hear them as they would require some disassembly and re assembly to fix. You would likely be able to re-use the materials.

kmetal, post: 461472, member: 37533 wrote: How did you test the

kmetal, post: 461472, member: 37533 wrote: How did you test the sound?

mostly with my ears.. I can hear a very low frequency rumble in the room when the house's AC is running.

Using the SPL meter in there (c-weighted, slow) I see the ambient noise level is like 56-58DB.

Sticking my ear up to the silencer vent I, it seems the rumbling is louder coming from there.

Thats about as scientific as I got.

kmetal, post: 461472, member: 37533 wrote: What frequency is the low noise, is it a fairly sharp peak or a wide one?

Im not sure how to answer that. Its pretty low frequency. If I play my drums without earplugs in for a little while the noise magically vanishes! :D

kmetal, post: 461472, member: 37533 wrote: What type of hvac is that?

its not really HVAC. The sinecers is just connected to a Fantech ERV unit. The unit isnt even turned on at this point. Its the HVAC sound for the REST of the house spilling into the room.

kmetal, post: 461472, member: 37533 wrote: What type of ducting, hard or soft?

Flex duct going into the silencer.

kmetal, post: 461472, member: 37533 wrote: What size is the ducting?

The Fantech is 4" ouputs, so 4" duct going into the silencers, and then the cross-section within the silencer expands in order to slow down the air velocity.

But like I said, the fantech isnt even running at this point.

kmetal, post: 461472, member: 37533 wrote: What is the ducting attached to, and how?

?? the silencer, via a 4" take-off.

kmetal, post: 461472, member: 37533 wrote: Is the ducting and other hvac all attach to existing structure or new room?

The "inner leaf" silencer is screwed to the concrete wall, and does not touch the inner leaf. The OUTTER leaf silencer does just sit in the rafters of the existing structure.

It was a compromise I had to work around.

kmetal, post: 461472, member: 37533 wrote: Is the low end from the the hvac or is it bleed from drums out of the room?

Its just low end rumble from the AC cooling the rest of the house. But doesnt bode well for my low end isolation.

kmetal, post: 461472, member: 37533 wrote: Is there a double wall on the door side?

Yes.

kmetal, post: 461472, member: 37533 wrote: In the second picture, is the silencer mounted to the existing structure or new room?

existing structure. The concrete wall of the basement. It doesnt touch the inner leaf.

kmetal, post: 461472, member: 37533 wrote: At the point of the inlet, the wall penetration, is the new wall touching the inlet?

no.

kmetal, post: 461473, member: 37533 wrote: I Also saw a couple o

kmetal, post: 461473, member: 37533 wrote: I Also saw a couple of structural things, which could be improved on, but are unrelated to the hvac. Im not sure if you care to hear them as they would require some disassembly and re assembly to fix. You would likely be able to re-use the materials.

Sure, I'd be open to hearing them.

Im a bit confused as to the hvac system generaly for the studio?

Im a bit confused as to the hvac system generaly for the studio? Is it just the air exhange? What are you using for heat and cooling?

Im also confused as to how you still have acess above the studio ceiling. If there is concrete behind two walls (assuming the studio is in the basement corner), and the other two walls have the inner studio leaf, and the outer leaf (which should be connected to the basement concrete floor, and house joists). How is there acess? The ceiling of the studio (and walls) should be encapsulated completely by the concrete and outer leaf.

Heres a couple tests. You can plug the silencer opening with a couple scrap peices of drywall an see if the noise goes away.

If you have a loud speaker, like a PA or loud stereo, you can play some test tones outside the room loudly and see what frequency is loudest bleeding into the room. You can do this with the hole plugged and not plugged, which will tell you what the hole could let in.

The main structural thing im curious about is why the ceiling joists are running under the house joists instead of running in between them. It seems to sacrifice a few inches. I might be missing something here.

Jason Morris, post: 461474, member: 51197 wrote: mostly with my ears.. I can hear a very low frequency rumble in the room when the house's AC is running.

Using the SPL meter in there (c-weighted, slow) I see the ambient noise level is like 56-58DB.

Sticking my ear up to the silencer vent I, it seems the rumbling is louder coming from there.

Thats about as scientific as I got.

Thats a bit loud. Is the houses hvac connected in any way to the studio? Oris it just an ERV unit running in and out of the room.

Jason Morris, post: 461474, member: 51197 wrote: its not really HVAC. The sinecers is just connected to a Fantech ERV unit. The unit isnt even turned on at this point. Its the HVAC sound for the REST of the house spilling into the room.

Thru ducting, or possibly a physical connection of some sort?

Jason Morris, post: 461474, member: 51197 wrote: Flex duct going into the silencer.

How is the flex duct mounted?

Jason Morris, post: 461474, member: 51197 wrote: The "inner leaf" silencer is screwed to the concrete wall, and does not touch the inner leaf. The OUTTER leaf silencer does just sit in the rafters of the existing structure.

It was a compromise I had to work around.

So neither silencer is physically touching the studio framing or walls? I consider the existing structure "the outer leaf"

kmetal, post: 461476, member: 37533 wrote: Thats a bit loud. Ou

kmetal, post: 461476, member: 37533 wrote: Thats a bit loud.

Out of curiosity, what would one expect?

I will say that the room is exceptionally quiet. I'm pretty sure I can hear my hair growing.

But maybe its just really good at blocking high and mid-range frequencies, and xomething fell apart for me at the lowest end of the frequency spectrum.

kmetal, post: 461476, member: 37533 wrote: Is the houses hvac connected in any way to the studio? Oris it just an ERV unit running in and out of the room.

Not yet. I nfact, I do not even have the other set of silencers cut in yet. Only the "exhaust" silencers are built and going thru the wall.

I wanted to test things before I cut another hole in the wall and tackled another set of silencers. I have easy access to the other side of the wall, so saving that portion till later was feasible for me.

I AM planning on installing a new HVAC system to service the top floor, and I think I am going to use a line off that (along with a motorized damper) to get conditioned air into the room.

But like I said, I havent got that far yet.

kmetal, post: 461476, member: 37533 wrote: Thru ducting, or possibly a physical connection of some sort?

Im not sure. Its such a low frequency that it seems to be coming from everywhere, but it does seem to be louder coming from the vent of my silencer.

kmetal, post: 461476, member: 37533 wrote: So neither silencer is physically touching the studio framing or walls? I consider the existing structure "the outer leaf"

No. neither silencer is touching the walls of my drum room. One of the silencers IS touching the rafter of the office area adjacent to the drum room, but it is NOT making ANY contact at all with the drum room.

It IS making contact with the other silencer via 3/4" thick neoprene rubber.

I used this to build a coupler which joins the two silencer boxes between the leaves:

https://www.amazon.com/gp/product/B01CT6TIW8/?tag=r06fa-20

Again, the silencers are not touching the inner walls of my drum room. I left a gap around the permiter of the silencer where it penetrated the wall and filled it in with backer rod and caulk.

OK. I just covered the silencer vent with some mineral wool and

OK. I just covered the silencer vent with some mineral wool and a 3/4" piece of MDF.

The low frequency noise didnt go away, which makes me wonder if it isnt coming in thru the ductwork across the ceiling and in that soffit we built.

And maybe that low frequency spillage is amplified due to the natural room nodes?

I dunno. this is voodoo to me.

All i really know if "make it dense, leave a 4" airgap, insulation is a damper, and caulk the hell out of it" :/

Jason Morris, post: 461477, member: 51197 wrote: Out of curiosit

Jason Morris, post: 461477, member: 51197 wrote: Out of curiosity, what would one expect?

I will say that the room is exceptionally quiet. I'm pretty sure I can hear my hair growing.

20 dba is the target ambeint noise level for a studio.

Chart-

http://www.sengpielaudio.com/TableOfSoundPressureLevels.htm

PDF-

http://tech.ebu.ch/docs/tech/tech3276.pdf

Jason Morris, post: 461477, member: 51197 wrote: I wanted to test things before I cut another hole in the wall and tackled another set of silencers. I have easy access to the other side of the wall, so saving that portion till later was feasible for me.I AM planning on installing a new HVAC system to service the top floor, and I think I am going to use a line off that (along with a motorized damper) to get conditioned air into the room.

But like I said, I havent got that far yet.

Its important to use large, lined ducting, and incorperate some right angle bends in the duct to minimize bleed. The damper will control the temp.

Jason Morris, post: 461477, member: 51197 wrote: Its such a low frequency that it seems to be coming from everywhere, but it does seem to be louder coming from the vent of my silencer.

Im guessing its mechanical noise. Does it only happen when the AC is on? Where is the AC unit located?

Jason Morris, post: 461478, member: 51197 wrote: OK. I just covered the silencer vent with some mineral wool and a 3/4" piece of MDF.

The low frequency noise didnt go away, which makes me wonder if it isnt coming in thru the ductwork across the ceiling and in that soffit we built.

Its a possibility. Anything that would travel along the ducting should not penetrate those walls. It would just eminate from the source, thru the air space or even walls.

Im wondering that its a mechanical vibration traveling along the existing house sturcture and bleeding into the studio. If it was rigid ducting not useing iso mounts for it could be an issue.

What about your water heater/boiler? That could be a culprit.

Jason Morris, post: 461478, member: 51197 wrote: And maybe that low frequency spillage is amplified due to the natural room nodes?

It could be inherent in the inside out method. A series of small panels resonates at a higher frequency than larger ones, just like a small vs large cymbal. Not being super well versed in the method i cant say for sure. It seems it would be discussed if it were a common issue. Id double check at Sayers site. Id also love to see test data on the method.

Rods book states the ceiling assembly in he describes has a resonance of like 19hz. If you have similar mass i would expect the same result.

This is where im thinking its mechanical noise, or the inside out method.

At the wave cave, there was a regular thru wall AC unit on the rear wall of the control room. The first builder built a booth in the control room, with steel studs, and resillient channel on both sides. The booth walls were connected to the inner control room wall, and both control room and booth walls were built on top of the same wood framed floor, resting on the concrete. He didnt fill the deck with sand. All the walls (booth and control room) were connected to the studios ceiling which is second floors floor made of planks, in an old mill.

When the AC is on the U87 mic would pick up a low frequency rumble. This didnt occur when drums or the dehumidifier were going in the main room, or at all in the other booths (built properly).

The vibration of the AC was traveling down the CR wall, and thru the floor into the booth. Bypasing the booths walls.

Im suspecting something similar in your case.

Holy crap. 29db doesn’t seem attainable considering how quiet th

Holy crap. 29db doesn’t seem attainable considering how quiet the room is and spl is saying 55-58. I can’t even imagine what 20 sounds like.

If it’s the AC from the existing structure I’m probably going to have to live with it and do things different on the next one. :/ not giving up yet just not sure what I can feasibly do that doesn’t involve destroying the room and rebuilding from scratch.

If you look at the video you can get an idea of where my mechanical room is. Basically there’s my drum room, a flight of stairs. And next to that is the mechanical room.. so it’s close.

The anecdotal testing seems ok. The wife is thrilled with how much more quiet things are, but as expected she said she can still just barely hear the kick drum... but that it wouldn’t keep her awake or bother her as she watches tv.

The sound of the drums inside the room.... insane. Holy cow. There is so much low end. Can barely hear the snare over the booming kick drum. Kick sounds like a canon, but not in a good way. Heh

Jason Morris, post: 461482, member: 51197 wrote: If you look at

Jason Morris, post: 461482, member: 51197 wrote: If you look at the video you can get an idea of where my mechanical room is. Basically there’s my drum room, a flight of stairs. And next to that is the mechanical room.. so it’s close.

Hmmm. Is that where the ac unit and boiler are?

Jason Morris, post: 461482, member: 51197 wrote: The anecdotal testing seems ok. The wife is thrilled with how much more quiet things are, but as expected she said she can still just barely hear the kick drum... but that it wouldn’t keep her awake or bother her as she watches tv.

Well thats encouraging. Its not too late to add another layer of drywall tho if theres any concern. The acoustics can be adjusted as you go, the isolation not so much.... Id think deeply about this.

Jason Morris, post: 461482, member: 51197 wrote: The sound of the drums inside the room.... insane. Holy cow. There is so much low end. Can barely hear the snare over the booming kick drum. Kick sounds like a canon, but not in a good way. Heh

It would be totally weird if the room sounded good as is, id question your tastes, or call you the luckiest person on earth. Bass trapping will go a long way in your studio. Also the position of the kit can have an effect too. No worries till a bunch of treatment is up.

Fyi, my cousins basement control room was about 11x14 without much bass trapping it sounded like there was a subwoofer on in certian spots. Part due to my bright idea on the ceilings added mass (face palm). He ended up moving before we did a full acoustic treatment. Room boom. Ugh.

Your perseverance is comendable sir.

kmetal, post: 461483, member: 37533 wrote: Hmmm. Is that where t

kmetal, post: 461483, member: 37533 wrote: Hmmm. Is that where the ac unit and boiler are?

The AC unit is outside, another 15 feet away or so. You can certainly hear it running in the basement though.

And that part of the basement is not below ground, so it's just framing/sheathing between the exiting finish basement/family room and the AC unit.

We have a walkout basement.

kmetal, post: 461483, member: 37533 wrote: He ended up moving before we did a full acoustic treatment.

Yeah, we bought this huge house with 5 bedrooms and two kitchens, expecting to have a ton of people living here for a while. My oldest two just moved out, and my wife's oldest will be going off to college soon,.

In another year it will be just she and I, and her youngest 50% of the time... in this 4800sq ft house.

I don't think we will be here for more than a few more years.

So yeah, this won't be my last studio.

But I would still like to figure out why this is happening. If I can't fix it I at least want to know where I went wrong so I don't make the same mistake again.

Oh you mentioned seeing something that I should tear apart and do over.. What was that?

Jason Morris, post: 461484, member: 51197 wrote: The AC unit is

Jason Morris, post: 461484, member: 51197 wrote: The AC unit is outside, another 15 feet away or so. You can certainly hear it running in the basement though.

And that part of the basement is not below ground, so it's just framing/sheathing between the exiting finish basement/family room and the AC unit.

We have a walkout basement.

This might be the culprit. If so they have mounts you can use to help it, although it wont help if its airborne noise, as opposed to seeping thru the ac's concrete pad. The issue could be lines the are running from the unit, attached to the wall, and running thru the structure.

Is the noise in the studio Only when the AC is on?

My other thought is do you use any light dimmers in the studio or on general?

You have a nice house man! You should see some of the dumps ive been looking at buying.

Ya know, :) instead of moving you could turn your house into a gigantic multi room studio!

Jason Morris, post: 461484, member: 51197 wrote: Oh you mentioned seeing something that I should tear apart and do over.. What was that?

The main thing that i questioned was why the studs for the new ceiling didnt get tucked between the bays of the the existing ones. Like rod pictures in the "independently framed ceiling" section.

The other was why you had access with the video camera to the space between the two ceilings. It seems like there should be an outer leaf (wall) sealing that off floor to ceiling, in front of the studio wall. I could be missing something with both concerns.

Overall everything generally looks good. And i meant to add that the excessive room boom is actually a good sign. It shows you've got massive, airtight walls, that are not letting anything vent out. All the air is trapped. Good isolation makes acoustics worse, hence the extensive room treatments required in well isolated rooms.

kmetal, post: 461487, member: 37533 wrote: Is the noise in the s

kmetal, post: 461487, member: 37533 wrote: Is the noise in the studio Only when the AC is on?

It is certainly worse. When the AC is OFF the SPL meter reads about 41-44 DB.

For kicks I used Decibel Meter Pro (an iphone app) and it read 30db in that room. I am sure the iphone isnt totally acurate, but would it really be THAT off?

maybe its just not picking up the low frequencies that the SPL meter does.

Both the SPL meter and the app were set to C-weighting.

kmetal, post: 461487, member: 37533 wrote: My other thought is do you use any light dimmers in the studio or on general?

No, I havenet installed lighting yet. its just a plug-in light right now.

kmetal, post: 461487, member: 37533 wrote: You have a nice house man! You should see some of the dumps ive been looking at buying.

Ahh thanks man. The downside of it being a nice house is that it came with a large finished basement which the wife was adamant I could NOT destroy in order to build.

That made things really complicated. I was relegated to one tiny unfinished portion of the basement.

kmetal, post: 461487, member: 37533 wrote: Ya know, :) instead of moving you could turn your house into a gigantic multi room studio!

Ha! That would be nice. Maybe the next place.

kmetal, post: 461487, member: 37533 wrote: The main thing that i questioned was why the studs for the new ceiling didnt get tucked between the bays of the the existing ones. Like rod pictures in the "independently framed ceiling" section.

Oh! that ones easy!

The inside-out method! when you do the inside out method you can still push the drywall up to like a half inch from the existing joists.

It is true that the joists stick out farther, but they provide a place for me to put the mineral wool I will use as treatment.

If you sketch out some joists on a piece of paper and then draw the sheathing beneath them you should see that tucking the "inner" joists between existing joists, or doing them below the sheathing (via inside-out) method works out to the same ceiling height, at least acoustically.

kmetal, post: 461487, member: 37533 wrote: The other was why you had access with the video camera to the space between the two ceilings. It seems like there should be an outer leaf (wall) sealing that off floor to ceiling, in front of the studio wall. I could be missing something with both concerns.

THAT is because THAT portion was part of the finished basement that I was not allowed to dismantle. :/ what you saw was outside the drum room.

kmetal, post: 461487, member: 37533 wrote: It shows you've got massive, airtight walls, that are not letting anything vent out. All the air is trapped

Yeah. it seems I pretty air tight. But it also seems I did something wrong. While I was in there this morning with the SPL meter, my step kid was stomping around upstairs and I could totally hear him. And I do mean STOMPING. the kid is incapable of any other form of ambulation. But it's still pretty discouraging. I'm wondering if I compressed too much insulation in the ceiling.

Jason Morris, post: 461489, member: 51197 wrote: It is certainly

Jason Morris, post: 461489, member: 51197 wrote: It is certainly worse. When the AC is OFF the SPL meter reads about 41-44 DB.

For kicks I used Decibel Meter Pro (an iphone app) and it read 30db in that room. I am sure the iphone isnt totally acurate, but would it really be THAT off?

maybe its just not picking up the low frequencies that the SPL meter does.

Both the SPL meter and the app were set to C-weighting.

Well that proves part of the problem. 10db extra is a big thing. The question now is how the transmission is occuring.

40db range is much more like it. If i recall the cave measured somwhere around 35db in the main room.

Yes, the iphone is That off! I experienced the same thing when working as a consultant/sound manager at a waterfront performance spot. 12db difference between the iPhone, and two different spl meters, c weighting. Like you i suspect the defficincey in the low frequency pickup of the mic.

Where the iphone is useful if for a spectrum analyzer. Perhaps not the most accurate, but for rough guesses its cool, far cheaper than a purpose built one.

I would check with a spectrum app and see if the same frequencies peak next to the ac, in the house right near the ac, and in the studio. This can verify the ac issue and problem frequencies. I suspect 60hz. Even the limited iphone thing should shed some light on this.

Worth noting is you could gain a couple db once the internal insulation is installed.

Also, the stc ratings are frequency dependent. So at 1k a wall blocking 55db is gonna block like 20db at 100hz. Roughly speaking. i dont have my chart around.

Jason Morris, post: 461489, member: 51197 wrote: Ahh thanks man. The downside of it being a nice house is that it came with a large finished basement which the wife was adamant I could NOT destroy in order to build.

That made things really complicated. I was relegated to one tiny unfinished portion of the basement.

So you know what to look for next time eh?

Jason Morris, post: 461489, member: 51197 wrote: It is true that the joists stick out farther, but they provide a place for me to put the mineral wool I will use as treatment.

If you sketch out some joists on a piece of paper and then draw the sheathing beneath them you should see that tucking the "inner" joists between existing joists, or doing them below the sheathing (via inside-out) method works out to the same ceiling height, at least acoustically.

Phew.

Jason Morris, post: 461489, member: 51197 wrote: THAT is because THAT portion was part of the finished basement that I was not allowed to dismantle. :/ what you saw was outside the drum room.

If the studio leaf, is not fully enclosed by the outer leaf, this could be the crux of the whole thing. With the AC adding to the problem.

Jason Morris, post: 461489, member: 51197 wrote: Yeah. it seems I pretty air tight. But it also seems I did something wrong. While I was in there this morning with the SPL meter, my step kid was stomping around upstairs and I could totally hear him. And I do mean STOMPING. the kid is incapable of any other form of ambulation. But it's still pretty discouraging. I'm wondering if I compressed too much insulation in the ceiling.

Wondering if that opening isnt the issue. If the studio isn't a room in a room, then the isolation would be significantly compromised.

The other thing could be any connection physically between the existing structure and studio. Does the silencer box or anything else, wires, pipes, ect connect the two rooms?

Have you measured the spl in the studio with drums playing, and 3 feet outside the door with the drums playing?

kmetal, post: 461491, member: 37533 wrote: If the studio leaf, i

kmetal, post: 461491, member: 37533 wrote: If the studio leaf, is not fully enclosed by the outer leaf, this could be the crux of the whole thing. With the AC adding to the problem.

It is fully enclosed, but its hard to describe how we did it. But being a glutton for punishment, I will try...

The basement was almost fully finished. There was a small space that was NOT finished. That was the area I got to use for my drum room.

as you walked from the finished room into the unfinished room and turned around to see the studs, you could see the ceiling of the finished room was soffited down in that area.

When I was building my silencers, I stowed one in that soffited area (which you saw in the video).

THEN when it was in place, we build a small wall which was placed on TOP of the existing wall, to cover the soffited area, and we sealed it off really well.

That completed the "outer leaf".

THEN we built the inner leaf of the drum room wall.

Hopefully that makes sense.

kmetal, post: 461491, member: 37533 wrote: The other thing could be any connection physically between the existing structure and studio. Does the silencer box or anything else, wires, pipes, ect connect the two rooms?

EVERYTHING goes thru the existing ceiling joists of that room. water pipes, wires, and a couple of HVAC lines feeding the dining room above.

however, we were very careful not to allow any framing or sheathing from the inner leaf to touch those joists.

The only thing that could feasibly be touching from one leaf to the other is insulation.

kmetal, post: 461491, member: 37533 wrote: Have you measured the spl in the studio with drums playing, and 3 feet outside the door with the drums playing?

Not yet. I'm waiting for my buddy to come over and help out with that. I tried doing it myself with the SPL meter set to "hold" which grabs the highest peak and displays that.

That was very depressing.

So, there IS one more thing. I may need to build one more small wall in the hallway adjacent to the drum room, towards the other side of the room..

ugh. Im going to make another video to show you. too hard to explain..

Also.. wow.. you can TOTALLY hear the AC unit as Im walking thru the finished basement.

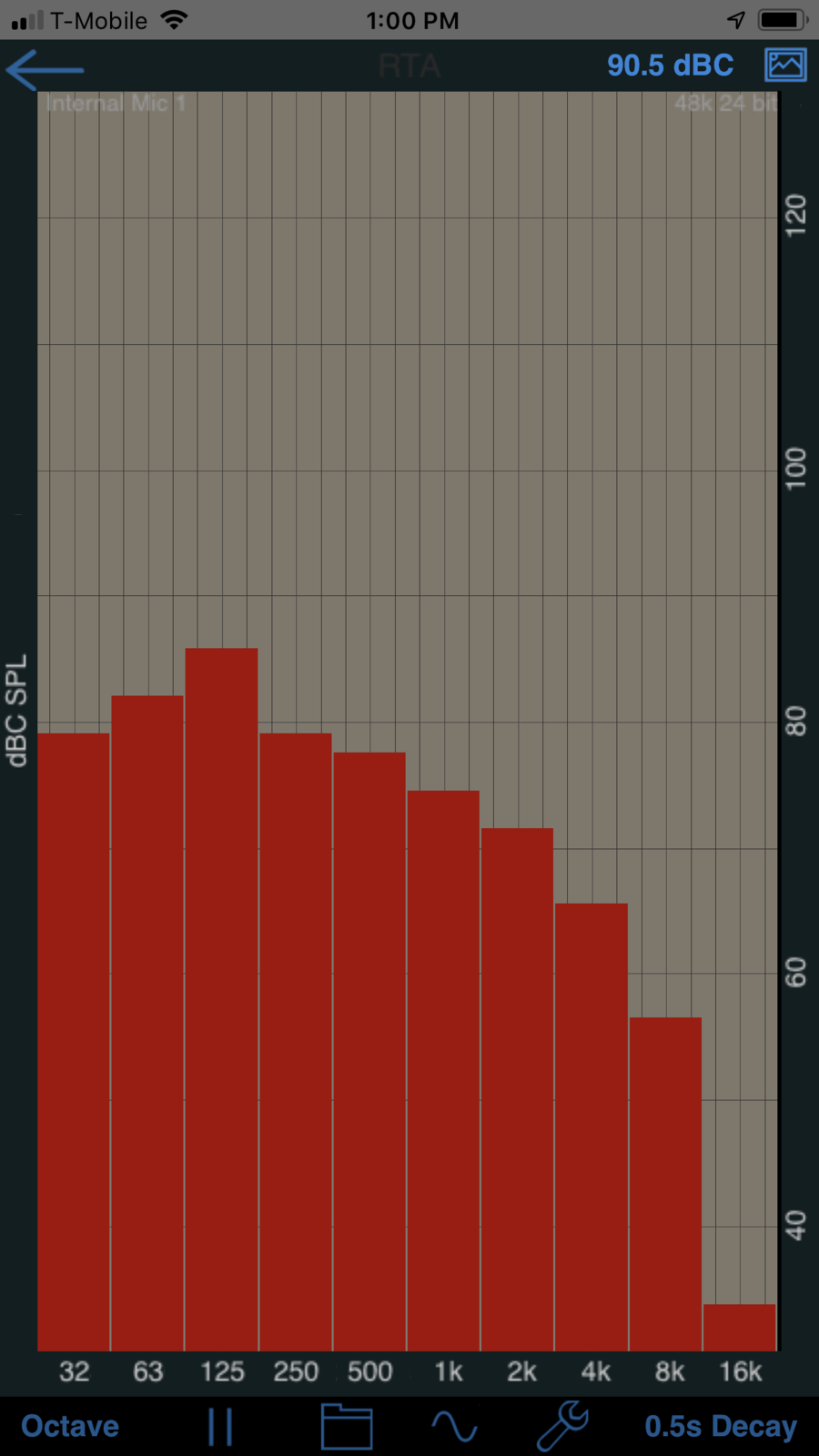

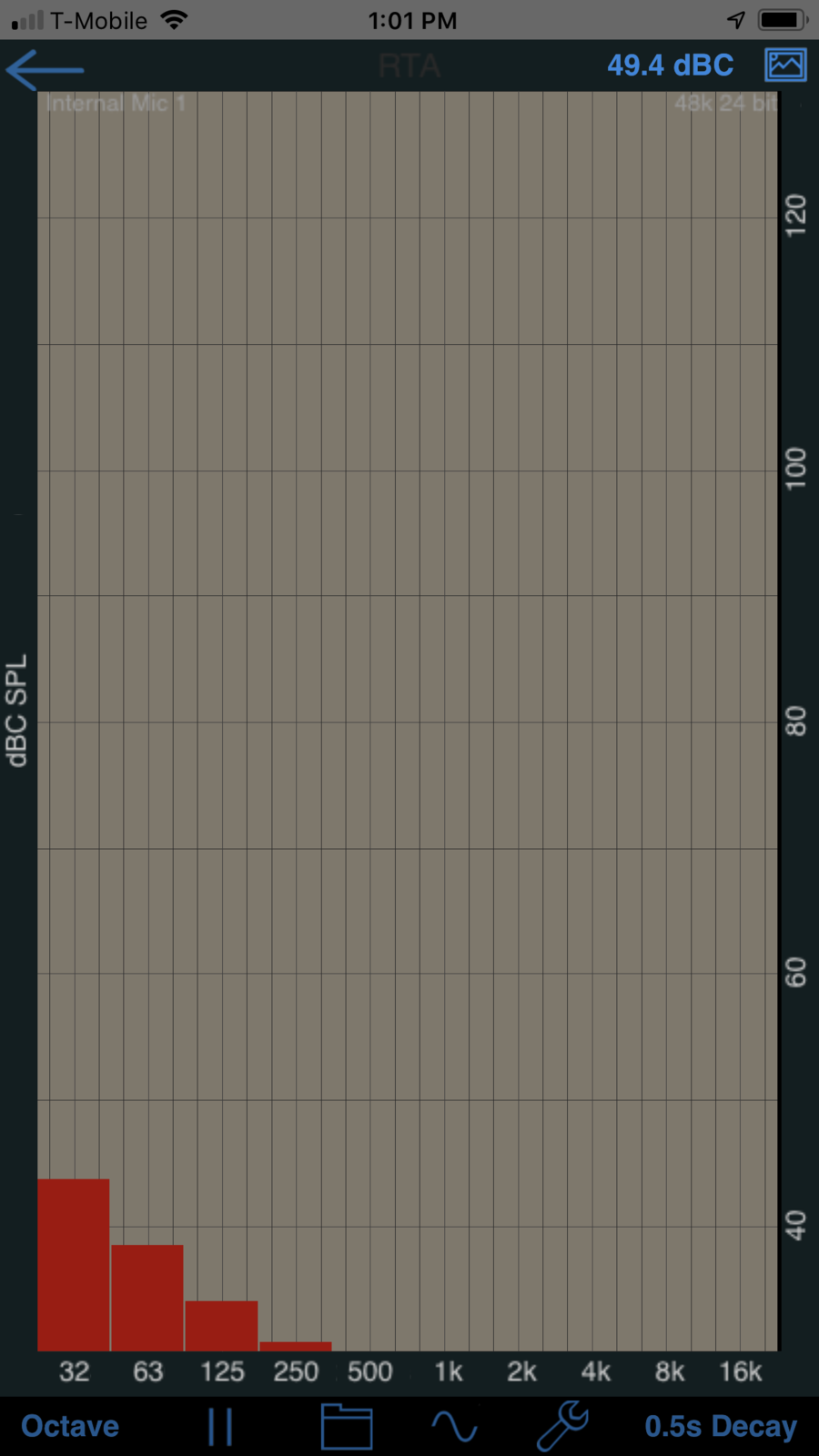

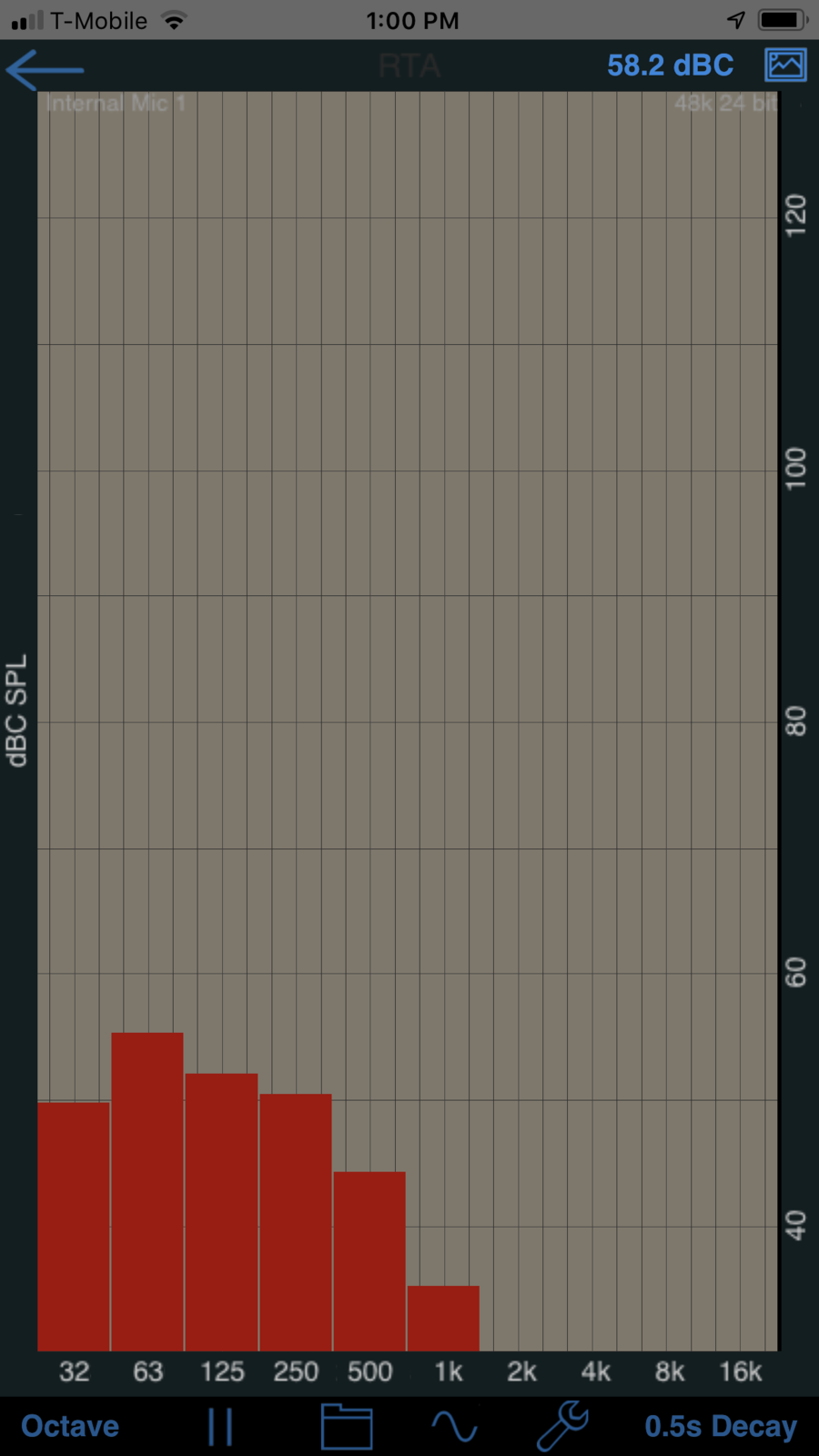

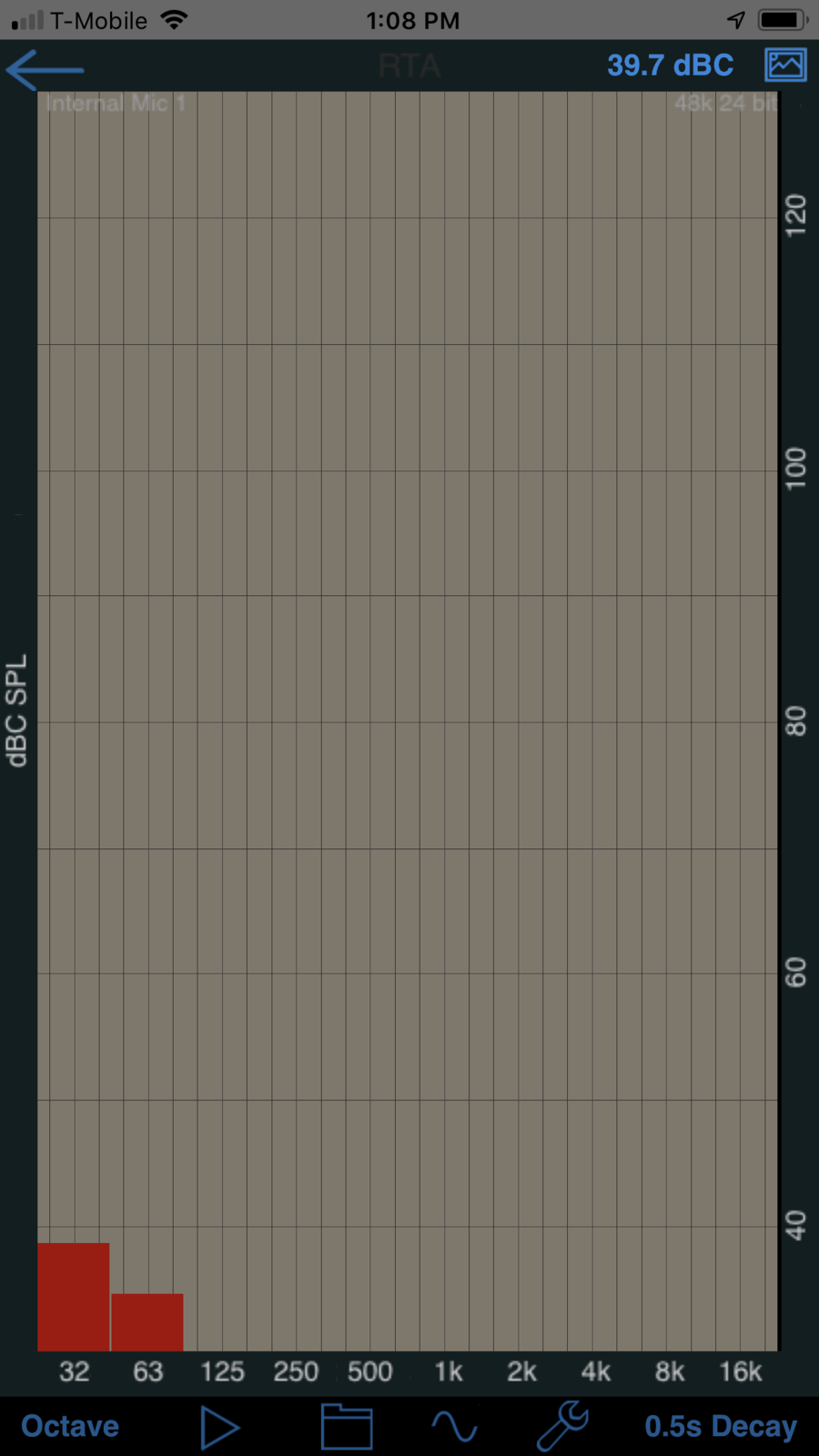

So, i did what you (brilliantly) suggested and used the RTA app

So, i did what you (brilliantly) suggested and used the RTA app on my iphone, which is part of AudioTools...

it looks like my problem frequency is actually 32hz. Thats what I am hearing in the drum room.

and my AC unit is also crazy loud.

Im uploading a couple screenshots from my iphone.

One is taken right next to the AC unit.

Another from inside the house on the other side of the AC unit, and a third from inside the studio.

In the last pic (studio)You will see something at 125 and 250 registering. that is hand noise from me fumbling around taking the screenshot.

When im just holding it only 32 and 60 are registering at all.

Jason Morris, post: 461492, member: 51197 wrote: It is fully enc

Jason Morris, post: 461492, member: 51197 wrote: It is fully enclosed, but its hard to describe how we did it. But being a glutton for punishment, I will try...

As long as its sealed your good. Does each outer leaf have the same mass?

Jason Morris, post: 461492, member: 51197 wrote: EVERYTHING goes thru the existing ceiling joists of that room. water pipes, wires, and a couple of HVAC lines feeding the dining room above.

however, we were very careful not to allow any framing or sheathing from the inner leaf to touch those joists.

The only thing that could feasibly be touching from one leaf to the other is insulation.

What type of insulation? Is it like barely touching or packed in? If its packed tightly it could count as a hard physical connection.

Rod specs 25% compression for the mineral wool fire safing that touches both the isolation wall and the existing ceiling.

Jason Morris, post: 461493, member: 51197 wrote: In the last pic (studio)You will see something at 125 and 250 registering. that is hand noise from me fumbling around taking the screenshot.

When im just holding it only 32 and 60 are registering at all.

So the ac is without a doubt contributing to the cause or is the entire cause. 60hz and 30hz, the octave below are where these machines run.

I tend to think its airborne noise bleeding right thru all the walls, and/or possibly some connected pipes shaking the existing structure.

It could be the unit itself shaking things, but since its on an earth dampened concrete pad, thats a good insulator. Does the house walls or foundation touch the ac pad? If not how close is it?

Gonna watch the vid asap.

From the pics your getting about 40db of isolation via all the walls which is a good amount at those frequencies.

Ran a test tone at 60hz in the studio, and got similar isolation level, then the problem would likely be a air borne. If you got more isolation with the test tone, that seems to say that some physical connection is bypassing the walls.

Im not a complete acoustical expert, so im trying to use what i know and suss things out.

This may be a case where some of the big dogs should be called. Im not sure if Andre Avare is still an active member here. Might be worth tagging him into the thread.

If you test the spl right outside the studio and inside, the difference should be what youd expect from the walls like that say 30db or so less inside the studio. If it isnt then that also seems to point to a flanking path shortimg out the walls.

kmetal, post: 461495, member: 37533 wrote: Does each outer leaf

kmetal, post: 461495, member: 37533 wrote: Does each outer leaf have the same mass?

Well, no. Three of the outer walls are 4" concrete. Everywhere else I beefed the sheathing up with 2 additional layers of 5/8" drywall.

kmetal, post: 461495, member: 37533 wrote: What type of insulation? Is it like barely touching or packed in?

Pinky fluffy insulation. its not packed in. I tried to compress no more than 20%

Jason Morris, post: 461496, member: 51197 wrote: Well, no. Three

Jason Morris, post: 461496, member: 51197 wrote: Well, no. Three of the outer walls are 4" concrete. Everywhere else I beefed the sheathing up with 2 additional layers of 5/8" drywall.

Pinky fluffy insulation. its not packed in. I tried to compress no more than 20%

Ok cool so the wall mass is good, and sealed.

Im thinking there should be a 1" airspace between the studio wall/insulation, and the outer leaves. Are the concrete walls the only walls which are "connected" by the insulation.

I know limp mineral wool doesnt effectively transmit vibration, according to the book and rods drawings. I am not sure if the same holds true for pink fluffy.

When you added mass, were the stairwell, and the hall area leading to the garage hall (the right hand wall when walkimg toward garage hall) areas you added mass to? Are those the outer leaves of the studio wall?

Im thinking you may be correct about that green section of wall needing an outer leaf. Its a bit difficult to picture in my head. It seems to me that the garage hall is functioning as the outer leaf presently, and if so would need to be massed up if the wall section wasnt built.

The upside is that little garage hall is a perfect echo chamber as is! A Great companion to the nice tight drum sound in the booth. Drool. Id certainly run a couple mic and speaker cables out there.

Love, love, love, gretch kits. The most astounding snare i ever played was a gretch at a music shop. Im not a drummer, but ive had a couple beater kits over the years. The sound just lept off this snare, you barely had to touch it.

Since the AC is a nuisance anyway, it might be worth thinking ab

Since the AC is a nuisance anyway, it might be worth thinking about some double deflection neoprene pads for it to rest on, and some (flex) isolation connectors to break the coupling between the house an ac unit.

An ac company, or industrial supply co, might be able to help recconend some products. If i remember correctly mason industries website had tons of these types of things.

I wouldnt do anything until i was sure, but it might be worth considering.

Also, maybe there is a control on the ac unit that can make it run slower or quieter. Probably worth a call to the maker or installer.

The AC unit is pretty old. like 20 years old. My cousin is an HV

The AC unit is pretty old. like 20 years old.

My cousin is an HVAC guy, so I can get a new unit for a pretty reasonable cost, but that is an expense that will have to wait. We are installing another AC unit along with a furnace up in the attic to cool the upstairs, as that old unit outside cant keep up. Its always like 10 degrees warmer on the upper level as it is on the main floor of the house.

The upside, is that I am planning to take a leg off the new AC/furnace system, coming down that hole I pointed out in the video and feeding that into the studio via another silencer.

Going to use a motorized damper to control it.

Hopefully THAT will go in next month. Maybe the following year I can think about replacing the ancient AC unit that is causing me so much trouble right now.

:/

kmetal, post: 461497, member: 37533 wrote: When you added mass,

kmetal, post: 461497, member: 37533 wrote: When you added mass, were the stairwell, and the hall area leading to the garage hall (the right hand wall when walkimg toward garage hall) areas you added mass to? Are those the outer leaves of the studio wall?

I beefed up the wall of the stairwell going from the basement up to the main floor.. That first one I pointed out between the mechanical room and my studio.

The door leading out to the garage.. that echo chamber area... nothing was beefed up there.

kmetal, post: 461497, member: 37533 wrote: Im thinking you may be correct about that green section of wall needing an outer leaf. Its a bit difficult to picture in my head. It seems to me that the garage hall is functioning as the outer leaf presently, and if so would need to be massed up if the wall section wasnt built.

Yeah. Nothing is beefed up in that area, so I think building another wall there is going to be the task for us this wed.

kmetal, post: 461497, member: 37533 wrote: The upside is that little garage hall is a perfect echo chamber as is!

yeah, it would be, except that it's isolated away from the drum room! The green wall seaparates that space from the studio.

Incidentally, that green wall is where my second set of silencers and the ventilation/hvac is going to come INTO the studio.

Does the wall in the stairwell have added mass floor to ceiling,

Does the wall in the stairwell have added mass floor to ceiling, or did it trace the steps? In the book it addresses maintaing isolation when a stairwell is involved.

Jason Morris, post: 461499, member: 51197 wrote: We are installing another AC unit along with a furnace up in the attic to cool the upstairs, as that old unit outside cant keep up. Its always like 10 degrees warmer on the upper level as it is on the main floor of the house.

The upside, is that I am planning to take a leg off the new AC/furnace system, coming down that hole I pointed out in the video and feeding that into the studio via another silencer.

Going to use a motorized damper to control it.

Id be very careful to make sure the new units are on isolation pads.

Id also make sure the unit has the capacity for the extra studio space, and the oversized ducting. In short id make sure the pro knows what you intend to do, and the specialized studio requirement details to keep it quiet.

Last thing you need is double the rumble.

Jason Morris, post: 461500, member: 51197 wrote: yeah, it would be, except that it's isolated away from the drum room! The green wall seaparates that space from the studio.

Incidentally, that green wall is where my second set of silencers and the ventilation/hvac is going to come INTO the studio.

The age old technique is to just have a speaker in the echo room, send the drums thru it, and record it with a mic. You can do this in realtime, or after the tracks are recorded.

If you're planning on a hole in that wall anyway, its probably worth a couple feet of cable. Redco makes xlr and 1/4" jack plates that fit in standard electrical boxes. Little bit of cable and a couple boxes would go a long way. You dont even need the boxes.

kmetal, post: 461501, member: 37533 wrote: Does the wall in the

kmetal, post: 461501, member: 37533 wrote: Does the wall in the stairwell have added mass floor to ceiling, or did it trace the steps?

Floor to ceiling.

I grabbed 4 bags of mineral wool, and propped them in the corners of the room. Crazy how effective that stuff is.

I couldn't resist and threw some mics up to see how things were sounding with just a little bit of mineral wool on the walls and 4 unopened bags propped up in the corners.

[MEDIA=audio]https://recording.o…

Attached files DrumTest1.mp3 (2.4 MB)

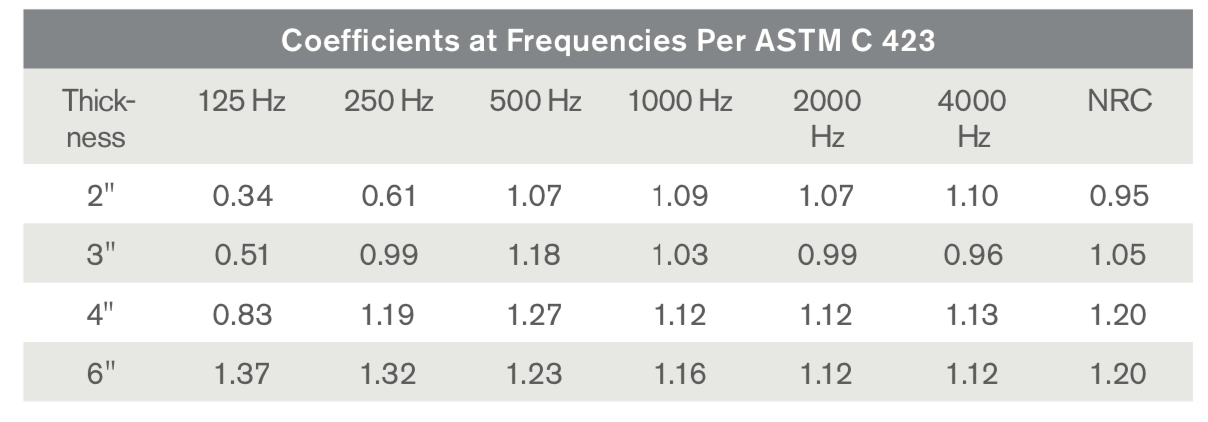

So, I have a boat load of mineral wool with specs as seen in the

So, I have a boat load of mineral wool with specs as seen in the attached screenshot.

I am planning on doing corner traps in pretty much every corner I can.

I measured out for the soffit traps you mentioned, Kyle.. I'm just not sure I can bring myself to do that. They would hang out so far into the room as to make it unpleasant to be in there.

I think I'm going to have to go with either straddles or superchunks in each corner, including the wall to ceiling corners. I'm leaning towards superchunks. I know they are more costly than a straddle type corner trap, but I have a lot of the mineral wool already, and the stuff I am using is easily available to me, so I don't mind the expense.

So here is what I am wondering..

Considering my 8' ceilings (which are still considered 'too low' for good drum sounds) should I cover the entire ceiling with mineral wool? If so, should I then cover that with plastic sheeting to recover some of the mids and highs?

Floor is going to remain reflective of course.

I was considering doing a 'wiggly wall' as I have come to call it (sorta like in the picture attached.. that's not my photo but its a design I'm planning to copy). That wall would be my Helmholtz resonator.

The back and side walls I was planning to cover in mineral wool, and again cover THAT with plastic sheeting, cutting strips out so that it wouldn't act as a vapor barrier.

My concern is that as a drummer I don't want the room TOO dead. But I also wonder if "totally dead" is the best option for a room as small as mine.

would spending time creating REW files be worthwhile in a live room? or is that more useful for control rooms?

Does anyone have any thoughts?

Jason Morris, post: 461504, member: 51197 wrote: My concern is t

Jason Morris, post: 461504, member: 51197 wrote: My concern is that as a drummer I don't want the room TOO dead. But I also wonder if "totally dead" is the best option for a room as small as mine.

I do have a too small drum room. It ended up near completly dead and I learned to work with it over the years.

I pretty good at faking it now with room simulators or plain reverbs.

I do have a hardware reverb for realtime mixing of my headphone mixes.

When ever I go play, I put on my headphones and get a feeling of a bigger room...

We'd all want the biggest room but get to work with what we have.

I'm sure you make yourself a good recipe that fits your needs ;)

Jason Morris, post: 461274, member: 51197 wrote: Well, last nigh

Doors are the most difficult to get done right imho. They always take some finesse.

Tricks ive found-

Bevel the door jamb so the type K fits snug.

Staple the rubber to the jamb before installing the jamb.

To get the rubber stapled straight, dry fit it in, while laying in the floor and table. Use another 1x board resting up against the rubber. This sandwiches the rubber in straight. Then you dont have to stretch it or warp it.

Use screws to install the jambs, this way you can partiallly screw them in, as your making adjustments and checking the door close for smoothness and seal.

Use a wide cabinet clamp to bend the jamb if needed. For instance the middle of the jamb isnt sealing up right. Leave top and bottom screwed in half way, then use the clamp to bend the middle, screw in the middle.

You may have to rip some width off the jambs so they are all even..

Use a flashlight and have someone run it around the seal, while checking it in the dark from the other side. Or leave the lights one side of the door, check the other side in the dark.

I also found it helpful to leave the door frame board with extra slack, then mount the hinges on door and frame, make sure it fits, then cut the frame board to size. This alleviates the need to measure the hinges super accurate relative to the top and bottom.

Best of luck.