dvdhawk - I'm starting a new thread with details on the proposed ICF building project. Here's the background information our moderators like.

Location: Western PA -USA

If you looked at a satellite photo of my location you would see all the forests and farmland, and you might think that outside -> inside noise wouldn’t be much of a problem in such a rural setting. Not true. We just have different problems than the suburbs and cities. We’re in the middle of a small cluster of homes along one of PA’s primary 2-lane roadways and we’re just 1/2 mile from Interstate-80. We’ve got great neighbors and we all try to be respectful and not make too much racket, early or late. I personally don’t need much volume to be happy and I’m much more likely to pick up an acoustic guitar or play an unplugged electric. But due to some unresolved karmic debt from a past life, my son plays drums. Thankfully he’s not a basher, but still, a 16 yr. old drummer playing the kind of music 16 yr. olds and his friends would play. (on the loud side) I own no less than 3 decibel meters, and have never measured the dBs inside or out when he's playing. I’d have to guess 95-100 dB inside would be the maximum inside level.

Project Description:

Multi-Function 55’ x 32’ Multi-Level Building attached to existing home.

Goals of the entire building project:

To make the most sound-proof and energy-efficient building possible on a reasonable budget.

2-car Garage with Workspace and Storage.

Recording and Production Space for my solo projects, band projects, and my 16-yr. old son’s band(s)

Production Space for occasional outside recording projects, and A/V post-production.

Control Room that can double as client-friendly Video Screening Room

Rehearsal Space for me and my son’s bands ( they practice a lot more than us old guys )

Workspace, Office Space, & Storage for the A/V Contractor business.

Project Status: Making final decisions about design, construction scheduled to begin with footer work in the spring, basement walls immediately after, - March if we’re lucky. It’s not too late to make changes!

Known Construction Challenges:

Attaching to existing house at correct heights.

Sloping lot - 30ft. drop over 300ft. length of lot.

Excessive ground-water needs adequate drainage.

Driveway needs reworked.

The patience of my wife of 25 years, who does not like change.

Noise Issues: Typical neighborhood noises - not complaining, just listing all the things that could wreck a recording.

Road noise - cars, trucks, Harleys, punks with car stereos I can literally hear coming a half mile+ away.

Moderate truck traffic with potential for much more if they make I-80 a toll road through PA. (which state lawmakers are trying to do)

The big trucks are a problem here. They're either coasting and Jake-Braking down one grade, or going like hell to get up the other side.

Neighbor’s idling big rig - sometimes rumbles for hours at a time, especially in cold weather.

Snow plows - an earthshaking rumble as they scrape the ice and snow off the roads in the winter.

Barking bird dog(s) in their pen - sometimes hours on end - year round.

Hunting related gunfire - sporadic and seasonal.

Lawn mowers - Neighborhood lawn mower brigade runs for hours - spring through fall.

Motorcycles (on and off-road) - loads of Harley traffic and the occasional ATV or dirtbike on the property behind us.

Helicopters - the good folks at Stat MediVac fly over regularly, between 2 local hospitals and interstate accidents.

Jets - that’s right... Jets. A couple times a month - F18s, A10s, C130s, etc. ripping through here full-throttle at tree top level. We apparently live at a navigation point for training flights and they hit a spot 1/4 mile East of here and bank hard North just outside my window. That leaves us in the loud wash, but it doesn’t happen enough to be a huge problem. And heaven help me, I love watching them go by, when I can look fast enough.

Vocation: I run my business out of our medium-size 2-story farmhouse style home.

Sound/Video Contractor - specializing in churches & schools. (95% of my business)

Professional Sound System Installation ( mixers, power amps, speakers, mics, racks, the works )

Video Projection Systems - ( screens, projectors, presentation software )

Theatrical Lighting - conventional lighting consoles & dimmers, plus new LED technologies

A/V production - Pro Tools & FinalCut Pro (5% of my business)

Special Interest / Corporate Video Production

Radio Commercial Production

Remote Recording - Live Concerts etc.

Recreation:

Still making music 2-3 times a month in a 3-pc rock / blues band

Golfing, fishing, motorcycling ( not enough free time do to any of these lately )

Research:

I have several great books including Rod's, and I've been doing my homework, reading everything on the Auralex & GreenGlue sites, at John Sayers' forum, and recently joined up here at recording.org to name a few resources.

Drawings and Pics to follow because, 'That’s all I need in life, a little place for my stuff.' - George Carlin

Topic Tags

Comments

It's been a few months since there's been anything to report, bu

It's been a few months since there's been anything to report, but I'm finally getting ready to get windows and doors installed. Then as soon as we're completely dried in, it's time to start chipping away at the wiring and interior construction.

Today my contact finally took me to the demolition contractor's warehouse where they have (almost) all the doors removed from the old defunct hospital. They've got hundreds of doors, but the owner told me they took the lead lined doors apart and sold the lead at scrap yard prices. (Lead is currently [[url=http://[/URL]="http://scrapmetalpr…"]trading[/]="http://scrapmetalpr…"]trading[/] at $1/lb.) Genius. I guess I should have bypassed my contact and got this deal done before they had a chance to think about it. Oh well, spilt milk...

Anyway, still a lot of really heavy doors to choose from 36" 42" 48" - hollow-core, solid wood, composite core, steel doors with oak veneer (you'd never know they were steel without the metal tag - some with safety glass most without.

They all still have some form of handles, most have the original hinges, some have the closers. We'll see if there's anything that would make the good beginnings of a super door. I lugged a few of them home to study.

As I was leaning them out to look at them you could immediately tell some were less than half the weight of some of the others. I was reading the badges on them, and it seemed the lighter doors had a 20 minute fire-rating. The extremely heavy ones seemed to be labeled "composite core" and fire-rated at an hour or more.

Does anybody know if there's any correlation between fire-rating and mass/density. Is the mineral core material they use to improve the fire-rating of any use, or concern, to me in terms of mass - or just a fire-resistant material?

The doors we brought back are seriously heavy. Just one door slab (flush, no frame) is about all two grown men can handle. Four of them had the 1/2 ton pickup seriously squatting.

A couple of them had Full Swing hinges on them. Would this be a factor - good or bad in geting a good seal around the perimeter of the door?

Any thoughts?

David, AFAIK, yes, the mass has a lot to do with the fire ratin

David,

AFAIK, yes, the mass has a lot to do with the fire rating. (It's also the materials that make up the door.) Without lookin' up all the stuff again, a time rating is given to an assembly in a real world test. It doesn't just consist of how long the door lasts in a fire, but also the ability of the seal around the door frame to stop smoke... IRC, fire rated doors are normally sold as a door/frame assembly.

Not that I really know what I'm talking about, but since mass is your friend... I might grab ye' ole bathroom scale and just weigh all the doors and pick the heaviest ones.

The only thing I might be concerned with about the full swing hinges, is whether they stick out the front face of the door enough to scrunch up or distort the seal as you close into it. (The same applies to any hinge, actually.)

Otherwise.... glad to see yer' still pluggin' away at it!!!

Now.... about that time frame comment you made about not taking as long as I did..... hehehehehe

(It really is amazing how time just keeps out running ya', ain't it?)

Thanks Max, I've been trying to visualize whether the full swin

Thanks Max,

I've been trying to visualize whether the full swing hinges have any big disadvantages. The only difference I can see is that they would swing the door completely out of the frame giving you the full width of the frame to move gear through. The extra angle would be outside the frame, so I don't think it would inhibit the seal - but I'm trying to make sure I'm visualizing it correctly. If they don't work, they've probably got thousands of the standard flat hinges like the other doors have. (extra heavy duty, full mortise, ball bearing)

If you had it to do over again, would you consider staining and sealing the floor before the messy part? I've been weighing the pros and cons of having the concrete polished while it's still reasonably clean. Bear in mind I won't be milling any lumber like you did. I would just have minimal sawdust and probably plenty of gypsum dust to clean off a much less porous surface if it were polished. Any thoughts?

I'd like to make a pilgrimage to "Sunny & warm NC" before I get down and dirty with the interior details, to see some of the finer build details of your pride & joy up close and personal. I'll contact you later about that. I'm still getting pounded with work (not complaining), so making time for a roadtrip will be a challenge.

I was thinking about the timeframe the other day. Big dig and footer 9-months ago, went like hell through spring, then took a few months off to get ahead of the bills. I figure I've got until 2015 before you really start to needle me.

Check, check... is this thing on? Hard to believe it's been thi

Check, check... is this thing on?

Hard to believe it's been this long since I've simultaneously had time and money to spend on the building project. There have been some general things done - windows, siding - but this will be the first relevant thing I've been able to do in a while.

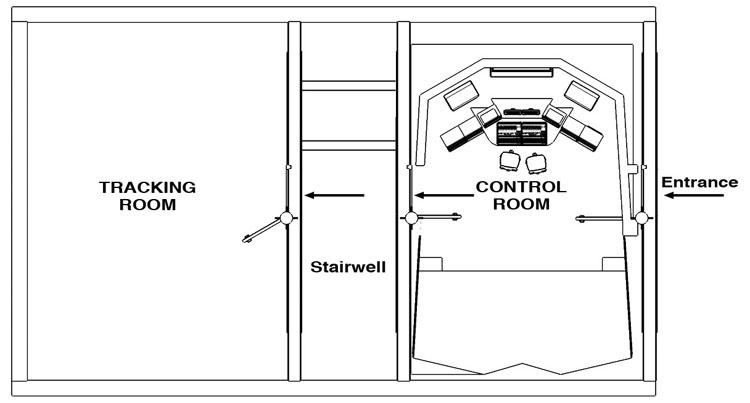

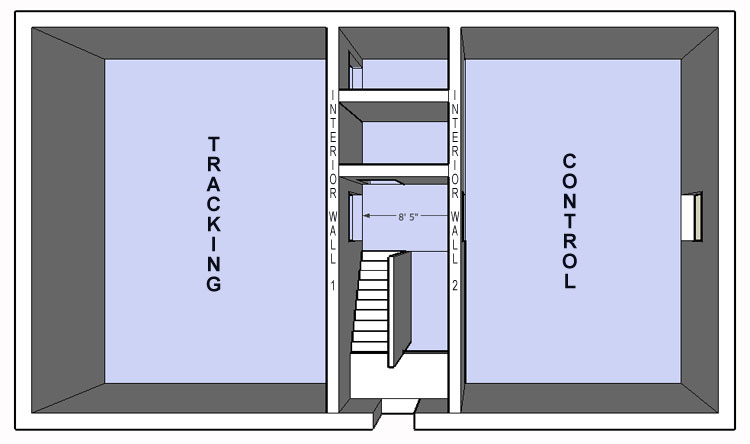

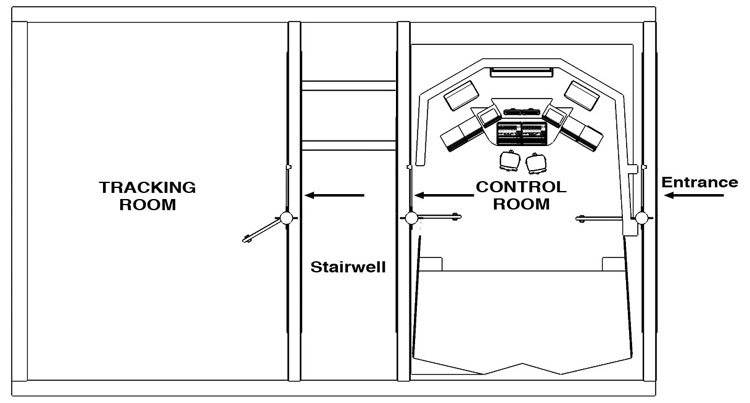

Next project, the airlock doors between the control room and tracking room. To review, the floorplan looks something like this:

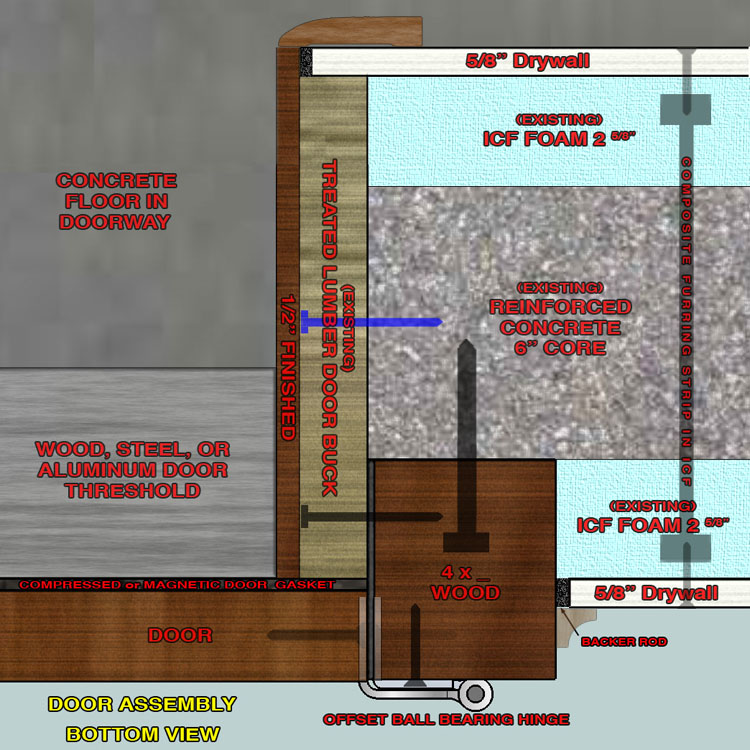

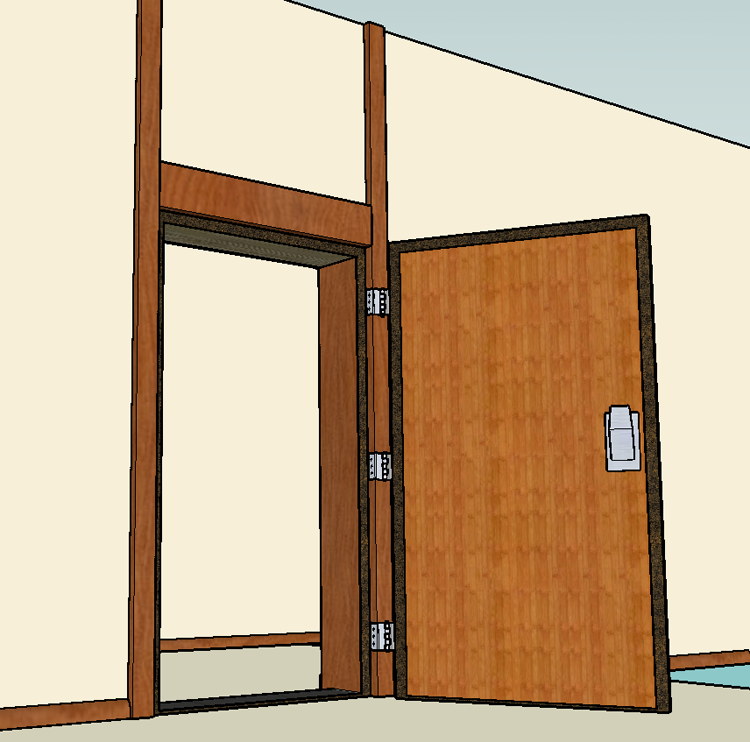

Last fall I was able to get some extremely heavy 4ft. wide oak finish doors that I would like to use for all the main doorways that equipment will be rolling through. These doors were taken from an old hospital that was being demolished, so they have all the hardware - but no frame/jamb. We'll have to bring in the concrete guys to cut the rough openings a foot or so wider, but for the price I paid for the doors I still think I'm ahead by a lot. My question is, since I have to change the rough openings and build my own door frames/jamb, etc. - is there a better way to get a good seal compared to the typical door inside the frame of a normal door. Since my door is currently a foot wider than the existing rough opening, and about 1 1/2" taller - I was wondering if I might get a better seal if we made the new opening 2 inches narrower than the door slab and didn't trim the door slab's height down. It would leave a 46" passage way and give an inch or more surface area around the top and sides of the door to build a really good seal. Using the inch border or more for a good compressed gasket or magnetic seal as illustrated below. Then 3/8" - 1/2" or whatever height we have to deal with for the threshold to gasket. I'm just wondering if it would be a better surface for gasketing than a series of staggered edges like the bank-vault door. The sound will have to travel through two of these heavy doors about 10 ft. apart and if additional mass needs to be added to the door it would be on the room side, opposite the gasket side. It will be a shame if we have to cover the beautiful oak veneer on either side, but we'll do whatever we have to do to get the isolation up if we test it and it isn't up to par. The walls on either side of the stairwell are also thick enough to put a door on both sides if necessary.

I was thinking we could frame it with something like 4x4s anchored into the concrete wall floor to ceiling and 4x4 across just above the door to help stiffen up the vertical 4x4s to support the weight of the door outside the opening. I don't know if I'm explaining it properly, hopefully the illustrations will help. (bear in mind the 4x4 wouldn't protrude 4" into the room, because we would remove the 2 5/8" of foam and anchor the 4x4s directly to the concrete wall)

Waste of time? Dumbest thing you've ever heard? Less airtight than the other way?

We'll have to get the rough openings cut out either way, so if you think it's a bad idea please say so.

Thanks.

Here is what the offset hinge would look like in motion - if it

Here is what the offset hinge would look like in motion - if it helps.

[[url=http://[/URL]="http://www.hawkprom…"]Offset Hinge[/]="http://www.hawkprom…"]Offset Hinge[/]

As long as you're bank vaulting the opening/door face, I can't e

As long as you're bank vaulting the opening/door face, I can't envision there being a problem with the offset hinges... but then too... I'm not Rod, nor am I quite as experienced.

I'm guessing that you probably don't have the mfr information or hinge model numbers to check the ratings... but they do look rather stout. I would only be concerned that with the mass you may end up needing to add to the door, that 3 hinges might not quite be enough to hold it.

Just thunkin' out loud here... I wonner' if adding two more regular EHD ball bearing hinges between the existing would be worth it... for insurance of a door that won't fail.

I'm gonna stick my neck out a bit and say that the plan of using a 4x4 post should work. Just be sure you're using an anchor system rated for your door's load.

Ooof... that's one I'm liable to get wrong David... but what the

Ooof... that's one I'm liable to get wrong David... but what the hey... it won't be the first time, right?

Structurally, I don't know if it makes a difference... but it might. That's for a more knowledgeable mind than mine.

Acoustically, I would think that it would be quite a bit more difficult to get an optimal seal on the door, unless the entire side facing edge of the door was also in the pocket. Which at that point, all I think you're really doing is putting bracing all along the exterior face of your wall... which might not be a good thing, unless you can really tie that exterior bracing/frame to the wall surface. (Make sense?)

With the door sitting inside the rough opening, once the door is set and shimmed, you're relying on the rough opening framing to both support the weight, and the rest of the door frame/sill to be in "friction" with the rest of the framing.

I hope that gives you at least a bit of food for thought until better minds can chime in with real understanding.

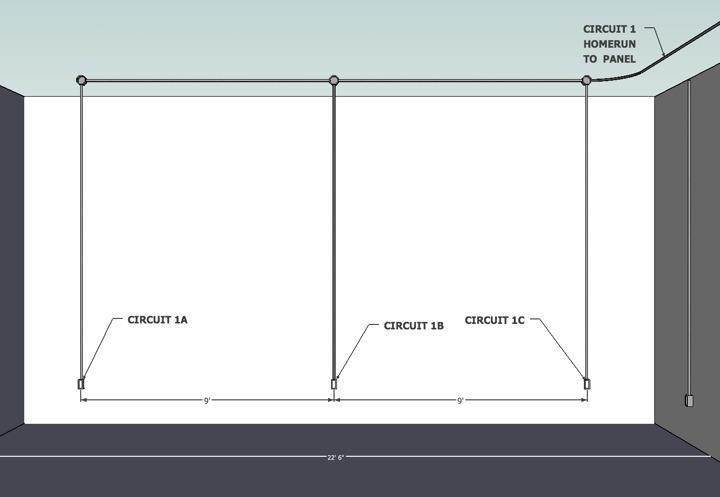

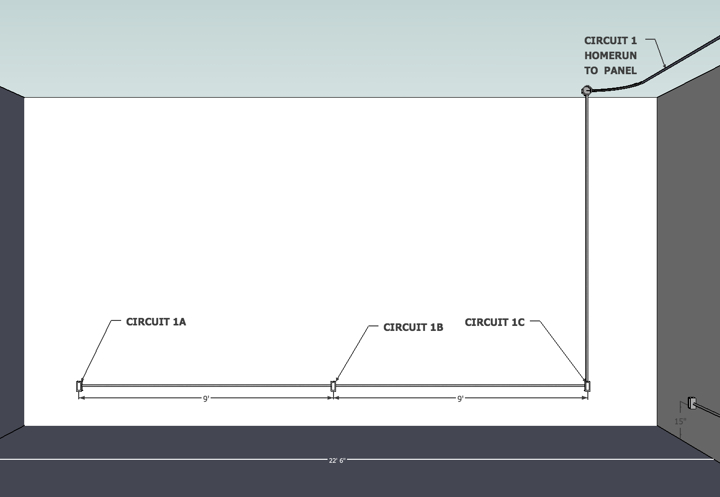

In the interest of keeping, "the low voltage wiring runs low in

In the interest of keeping, "the low voltage wiring runs low in the room and line voltage wiring runs high", would it be best to drop vertically down to all the individual receptacles - like Figure 1?

Or, (although I doubt it) is the typical horizontal box to box low approach OK since it's in conduit, as long as I keep the circuit homeruns to the panel high - as in Figure 2?

At this point, I plan to do Fig. 1, using stranded 12AWG THHN in rigid 3/4" EMT metal conduit (with isolated grounds). Even though it uses a few extra joints of conduit and fittings - and a lot more wire - my tendencies would be to avoid any junctions using wirenuts, and connect one receptacle to the next without an inline splice, unless one of the experts tells me it's not worth the added expense - or offers a better alternative.

Also, if using Fig. 2 is acceptable, should I bump the boxes up a little higher than the typical 15" to put a little more distance between the high voltage and low voltage runs? I don't want the low voltage so close to the floor they might catch a nail from any baseboard mouldings.

Thanks

I did all my wiring as figure 1... Two reasons... 1) I was abl

I did all my wiring as figure 1... Two reasons...

1) I was able to use romex and saved a LOT on labor for lack of conduit.

2) The home run to each box meant that there was no way that a low voltage conduit coming up out of the floor would interfere with an electrical conduit, nor would there be any chance of EMF interference due to proximity.

Also, in figure 1, my runs would be Circuit 1, Circuit 2, Circuit 3, etc... It has the added benefit reducing the amount of extra ground wire forming your star ground.

Thanks Max, I will be using regular romex in the garage and ups

Thanks Max,

I will be using regular romex in the garage and upstairs for the less critical power, but I was thinking stranded was the way to go for the studio power.

Did you use regular NM romex (PVC jacket) solid conductor? or an armor clad AC version?

So rather than have the North wall all on the same circuit, you've got 1A, 2A, & 3A on the North wall and then 1B, 2B, & 3B on the East Wall, and so on? or is every single receptacle 1:1 with a dedicated breaker?

Can you explain how that method reduces the amount of ground wire? I must be thick in the head tonight, cuz' I'm just not seeing it.

Thanks again !

Each clean duplex is a dedicated NM 12/4 solid, dirty duplexes a

Each clean duplex is a dedicated NM 12/4 solid, dirty duplexes are NM 12/3 solid, with each as a home run circuit on it's own breaker... whether it be clean or dirty power.

Clean and dirty sit next to each other in the tracking room in 2 quad boxes and there are two clean/dirty quad's in the control room. Clean power only in the hall and iso. Dirty everywhere else in the building. The dirty power is in there for maintenance, video lights, etc...

1:1 saves individual star ground compared to running conduit in daisychain... as all grounds in the star must be homerun back to the ground bus... and thus, labor and materials are less cost as you don't have all that extra time stepping up conduit sizes to handle fill.

I mixed clean and dirty to save penetrations, but used white recep's for clean, and beige for dirty.

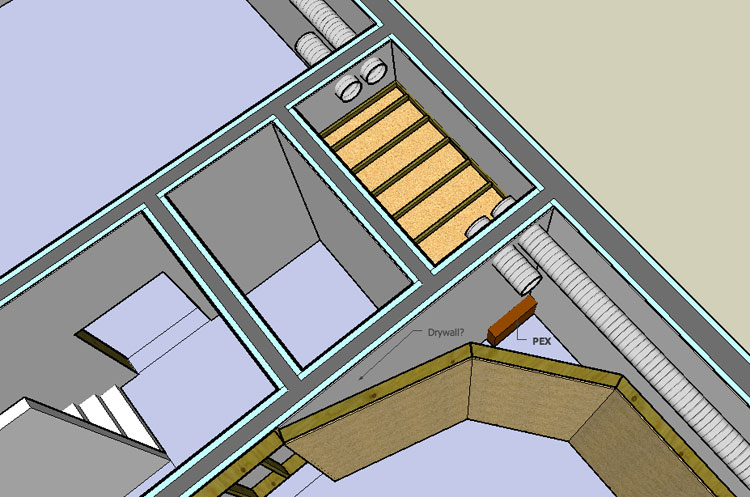

As we look forward, planning ahead a bit on the step after, the

As we look forward, planning ahead a bit on the step after, the step after next ....

When it comes time to drywall the interior walls of an ICF structure, can anyone tell me how putting the drywall directly against the styrofoam works in terms of the 'leaf' considerations? There's 2 5/8" of foam inside the concrete core with furring strips embedded in the foam every 8 inches. Attaching it should be relatively easy, but is there a better (naturally more difficult and expensive) way? The styrofoam isn't exactly what you would consider mass, but not exactly air either.

A significant portion of the outer perimeter walls are below grade, so that 'is what it is' - which would go:

dirt / gravel / water barrier / foam / 10" concrete / foam / drywall / room. [just add drywall]

I'm particularly wondering about the two interior walls between the control and tracking rooms wanting to avoid the dreaded triple-leaf. The layers for those two walls in their simplest form (barring adding any more layers) would go like this:

tracking room / drywall / foam / 6" concrete / foam / drywall / 8' 5" stairwell / drywall / foam / 6" concrete / foam / several inches of air / free-standing room within a room wall studs with drywall / control room.

I could go on, but is any of this anything I need to worry about? I'm hoping someone knows how this kind of wall assembly behaves.

This is a refresher of the basic shell of the basement as it stands (minus the stairs at this point).

The second thing I want to ask about is MLV. I know the consensus on MLV here is that it's not the best cost/performance ratio. Now suppose you were able to find several 4' x 30' rolls plus some significant scraps for virtually nothing out of pocket. So, if you take the cost out of the equation, what might you do with it - if it were you?

I'm thinking it might be useful in the stairwell construction. Any thoughts? Strips between the floor and the stringers? Over the treads? Strips between the stringers and the treads? On the landings?

Would it be useful under the bottom plate of the room-within-a-room walls?

Or is it more trouble than it's worth?

400' slip n slide?

"The styrofoam isn't exactly what you would consider mass, but n

"The styrofoam isn't exactly what you would consider mass, but not exactly air either. "

True, the styrofoam is more of a problem than air. The code suggests that you have to have drywall (paraphrase) on the interior side of an ICF type construction.

What you have to get passed is an interior framed wall assembly with an air gap from the existing exterior wall that you sheath with sheetrock.

To maximize the benefits, you want to frame an interior wall assembly...that is your intent yes, a basic mass/spring/mass assembly?

I'm sure the code you're reading is the same, but so we're liter

I'm sure the code you're reading is the same, but so we're literally on the same page, this is the specific [[url=http://[/URL]="http://nudura.com/L…"]ICC code document[/]="http://nudura.com/L…"]ICC code document[/] provided by the ICF manufacturer, that I've been using for reference. This is way outside my field, so I'm grateful for any help I can get.

4.2.2 Interior Finish.

4.2.2.1 ... ICFs exposed to the interior of the building must be finished with an approved 15-minute thermal barrier, such as minimum 1/2-inch-thick (12.7 mm) regular gypsum wallboard ...

In your interpretation does that mean I need to drywall the ICF in the voids which are not visibly exposed to the interior? I've had builders answer both ways, so I suppose I should probably call my inspector to see how he interprets the word 'exposed' - since he will be the final word. The bigger voids will house wiring, ductwork, and the PEX in-floor heating manifold.

Are those unseen walls still considered 'exposed' to the interior?

If the inspector says the drywall has to be there, will that be a problem?

I intend to drywall all of the walls with 5/8" that are part of the outer perimeter and will need to drywall the stairwell area. The only real question at this point would be the control room side of that interior stairwell wall.

The room-within-a-room framing is really to change the geometry of the room to a shape more suitable for a control room and provide spaces for the HVAC and bass traps.

4.2.2.1 ... ICFs exposed to the interior of the building must be

4.2.2.1 ... ICFs exposed to the interior of the building must be finished with an approved 15-minute thermal barrier, such as minimum 1/2-inch-thick (12.7 mm) regular gypsum wallboard ...

The idea is to protect the foam from heat and fire. So a double framed wall assembly with double 5/8 sheetrock (I assume this is part of your plan) >should

But that meeting of code will require a fire stop plan at the top of the walls to maintain the rating on the interior/air space part of a m/a/m, that if left unchecked and a fire started either from within or on the outside, would allow passage of fire to start or get inside of this "chimney" which has an unrestricted path to the upper living area.

Space, post: 387050 wrote: But that meeting of code will require

Space, post: 387050 wrote: But that meeting of code will require a fire stop plan at the top of the walls to maintain the rating on the interior/air space part of a m/a/m, that if left unchecked and a fire started either from within or on the outside, would allow passage of fire to start or get inside of this "chimney" which has an unrestricted path to the upper living area.

heehehehehe.... Welcome to the hell of Satan's Handcream

Max, you don't have to be so giddy about my satan's handcream he

Max, you don't have to be so giddy about my satan's handcream hell!

If it was ever exposed to a flame-source the ICF would produce obscene amounts of noxious smoke, but in the control room and tracking room in the basement - a fire couldn't burn more than a few inches before it met a fairly thick concrete barrier.

In addition to drywall and insulation, I can definitely see fire caulk going around the wood construction floor above the garage area to discourage fire/smoke/fumes from getting to the floor above. Because the smoke would be a killer, I'm putting smoke detectors in every room wired to a central alarm that would be audible (and with strobes) in all rooms (and my house next door). Plus carbon monoxide detectors in several places in and around the garage and mechanical room.

With the monolithic wall design I'm already airtight where the basement wall meets the floors above and below - even before the drywall. So, where am I going to need lucifer's lube there? Around the room-within-a-room framing? The wood framed stairwell?

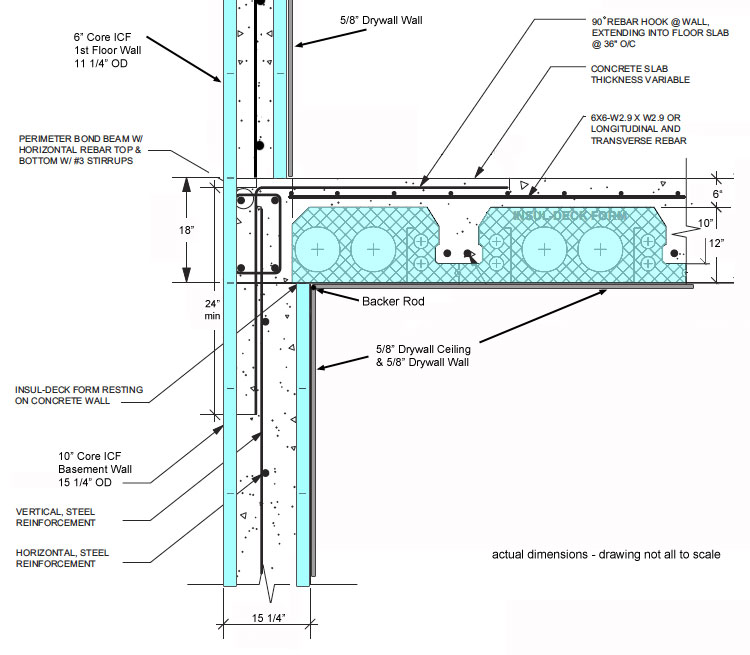

The walls and floor in question are 3 separate pours, but the result is about as monolithic as possible. As part of the concrete floor poured above the studio area, there a 18" rim of solid reinforced concrete above all the exterior basement walls as well as the interior/stairwell/iso walls. Everywhere a wall meets the floor above, 18" of concrete. Anywhere there's a span not resting on a wall, that's formed as shown below. Vertical rebar is embedded in the top couple courses of 10" basement forms, some straight up to bond to the 6" forms in the walls above, and some bent as shown to bond the floor to the wall.

This was the closest tech drawing I could find to modify to the specs of my situation. [not necessarily to scale, but the dimensions are real] I know the rebar at the bottom of the concrete beams is closer to 1 1/2" in diameter.

InsulDeck Spans

One from the way-back machine circa 1/21/10: This is the floor above the control room, before it was poured to the top of the form.

"Around the room-within-a-room framing? " Concrete burns too :)

"Around the room-within-a-room framing? "

Concrete burns too :) But if you have concrete on all sides of the perimeter then a fire stop may not be required. It is any penetration that can be breach by the gas or the actual fire that is going to be a concern locally. Based on the above photo, the exterior perimeter may get a pass...but if you have an interior framed wall assembly (control room/tracking room) there will be an area that could be breached, allowing passage from the one room to the other room...and this may be your point of concern with a fire stop.

Got it, thanks. Any thoughts on the MLV question? The second t

Got it, thanks.

Any thoughts on the MLV question?

The second thing I wanted to know was about MLV. I know the consensus on MLV here is that it's not the best cost/performance ratio. Now suppose you were able to find several 4' x 30' rolls plus some significant scraps for virtually nothing out of pocket. So, if you take the cost out of the equation, what might you do with it - if it were you?

I'm thinking it might be useful in the stairwell construction. Any thoughts? Strips between the floor and the stringers? Over the treads? Strips between the stringers and the treads? On the landings?

Would it be useful under the bottom plate of the room-within-a-room walls?

Or is it more trouble than it's worth?

400' slip n slide?

If you can get mass loaded vinyl, and the cost is nothing to you

If you can get mass loaded vinyl, and the cost is nothing to you, then it is a good product to have.

It isn't going to be much of any good as a barrier between plates and the concrete floor, nothing will take the place of a good 3 rows of caulk on the rat sill sitting on a level floor.

In your case, in the consideration of a fully decoupled /double wall assembly in a Northern region....you would install a vapor barrier on the interior side of the interior framing. At this point, theoretically, you could install the MLV with the mass attributes plus take the place of the VB, which would be a heavy mill plastic.

The one thing that matters, to prevent diffusion of vapor thru the overlapping layers, will be the seal at these overlapping joints...maybe a vinyl cement would be something to look into?

Where a hard framing member is, it isn't going to help as much as it would in the void areas. Like the stairwell walls would benefit, but the treads wouldn't make it worth the effort...now the area where the riser is, that if open could benefit if a contiguous layer were installed this would be better, like in the case of the vapor area.

camsr, gullfo, Thank you gentlemen, I appreciate your input.

camsr, gullfo,

Thank you gentlemen, I appreciate your input.

Glenn, do you have any thoughts on using the MLV in conjunction with the "Super-Chunk" bass traps, or ceiling clouds?

Camsr regarding the door situation, on the final draft I did change that Control Room door to swing in. Although I was considering whether or not it would be wise to add another (out-swing) exterior door or storm-door flush with the outside wall - given the thickness of that wall. The ICF is 15 1/4" O.D. (foam to foam) then add 1 inch air-gap and the thickness of the angled room-within-a-room wall (approx. 4 3/4" and I will be pushing 21" of wall thickness. That seems like a potential tunnel that would hold moisture on the north-east side of the building that rarely gets any direct sunlight.

Cam, can you explain why building code would object to an out-swing door underneath a balcony, or in this case deck? I'm a greenhorn, but don't see what would make that an worse than any other porch roof situation. I assume they are concerned something (snow for example) will prevent the door from opening, trapping someone inside? In which case, I assume there's an exception for storm-doors. I will certainly run all this by the local code authority, but I would like to educate myself.

Again, gotta run to a job - but thank you all for your time!

gullfo, post: 388794 wrote: i would use the MLV as limp membrane

gullfo, post: 388794 wrote: i would use the MLV as limp membranes in the room treatments -

Certainly another option. Good catch Glenn.

But there is going to be the issue of high frequency, like in the case of installing plastic over treatments, same effect.

I think, overall, the rooms would have to be tested to figure out what is required, and how this MLV is going to effect the overall response.

Is this an accurate procedure that you would use?

definitely test the room to spot any significant issues. like mo

definitely test the room to spot any significant issues. like most treatment approaches using broadband first, the limp membrane has broadband effects because it has enough density to have a range of modes across its surface and the proximity of the insulation to dampen widens the Q. using panels on top of POA (plain old absorption), or plastic under the cloth, to improve the MF-HF response is a good way to ensure the room response is even.

Aaaah, the beauty of having many different eyes looking at this

Aaaah, the beauty of having many different eyes looking at this from different perspectives. I would have used it in the construction of the stairwell, or something else stupid, and by all accounts completely wasted the MLV and needlessly complicated the stair construction. Rather than waste any of it on construction - a few beads of caulk under the bottom plate and I'll be able to save the full allotment of MLV to put to better use once the doors are in place and we can perform some meaningful tests. I hadn't considered using it in the treatments. And if it would have ever occurred to me, it would have probably been too late.

Thank you all for your suggestions! Brien, Glenn, camsr - much appreciated!

The building fund has taken another 1..2.. punch to the chops (s

The building fund has taken another 1..2.. punch to the chops (son's sophomore year of college / daughter's wedding). Slowly recovering, and looking forward.

As we get ready to get some sawdust flying during the cooler months, I'd welcome some input from you all.

If you had a few hundred bucks in the form of a store credit (that is going to expire soon ) at a store that sold tools, what would you buy to best serve the framing and finishing that are ahead of me? I don't do much large-scale woodworking, so I want to buy wisely. I do still occasionally make some custom flight cases by hand, so a real saw would be useful for cutting plywood once in a while. Although my normal trade is more Sawzall, grinder, and oscillating saw kinda work.

I believe I can borrow a radial arm saw and/or table saw from my dad for the duration if needed. So, I'm thinking about a [[url=http://[/URL]="http://www.sears.co…"]track saw[/]="http://www.sears.co…"]track saw[/] for cutting large sheet goods by myself. Near as I can tell that with a decent compound miter saw would be the best investment for me and give me a lot of capability for cutting precise angles - and they won't take up a ton of room when the dust settles.

I would be happy to hear other opinions from you guys who have a lot more building experience than I do.

Thanks!

While not a rough cut saw, a multi tool like this has proven to

While not a rough cut saw, a multi tool like this has proven to be invaluable for a myriad of jobs from cutting outlet pockets (high and low voltage) as well cutting trim and bolts and fabricating sheet panels etc.

[[url=http://[/URL]="http://www.homedepo…"]18-Volt JobPlus Base with Multi-tool Attachment-P340 at The Home Depot[/]="http://www.homedepo…"]18-Volt JobPlus Base with Multi-tool Attachment-P340 at The Home Depot[/]

This isn't an add for Ryobi. I own a Ryobi and am happy enough but every major brand has these at your usual locations.

Thanks John, It's a great suggestion, but luckily I already hav

Thanks John,

It's a great suggestion, but luckily I already have the Dremel corded version of an oscillating saw for just the kind of work you described. It's been a good investment for my regular work. And oddly enough my "Dremel tool", was made by Ryobi - love it.

If there's anything left, the cordless osc saw would be great.

Get the Kreg system!!!!!!!! I was an idiot for not getting one u

Get the Kreg system!!!!!!!! I was an idiot for not getting one until recently. Face frames and cabinetry in general is seriously simplified!

You don't need to get all the fancy clamps. You can use regular clamps just fine. Also, get a big set of the 3/4", 1" and 1-1/4" screws.

Finish and/or framing nail guns and a compressor are definitely in your future. A lot of guys like Paslode, but the nails are a bit more expensive. Again, I went with DeWalt for the 16 Ga nailer and found a decent Ryobi 18 Ga nailer for not much money. So far, they've both held up just fine.

Other options are a smaller joiner or the DeWalt DW735 planer.

I'm specific about the DeWalt, because the biggest PITA in planers is blade setup, and it can take up to a coupla' hours to reset blades. The DW735's blades have alignment pins that makes blade setup a 15 minute task.

Granted, I had to plane down all that lumber from raw stock, but when you get to the steps, cabinets, rack finishes, etc., having the ability to get precision milling done in the shortest amount of time will keep your attitude in better shape.

A small joiner will also make tasks of squaring up edges a lot easier. You can square edges on a table saw, but it's kind of a PITA to do it on a radial arm... unless you get a seriously stout saw that won't allow the blade assembly to flex.

You may also want to think about good quality saw blades, and clamps. You can't have enough clamps. (I have about 16 clamps, and I run out every now and then.)

One set of clamps I would strongly suggest are deep throat wood screw clamps. So many times, you need to clamp things well past the edge, and it's usually an inch or three deeper than regular 3" and 4" deep clamps.

If you're doing any laminate work, you might wanna keep an eye out for a vacuum press. Essentially, they're a big plastic bag that you put the sheet to be laminated in, attach it to your shopvac and suck all the air out. That vacuum really bonds the laminate to the sheetgood/substrate.

Oh... and the most important thing to keep you off the sofa... a ShopVac with extra long hoses!!!

My guess is that I've done a pretty decent job of spendin' your store credit, huh??

Gentlemen, thank you! Keep the suggestions coming. Max, you do

Gentlemen, thank you! Keep the suggestions coming.

Max, you do have a knack for torpedoing a budget. I knew talkin' tools would get you a little excited though. The credit will help, but I never expected it would cover everything. I have had every intention of kicking in whatever extra cash is needed to make sure I'm equipped with decent tools. I hate tools that don't work properly. I've got no patience for tools you have to fight every step of the way. My install tools are all of serious-get-some-work-done quality DeWalt, Milwaukee, Dremel, etc. The Dremel osc. saw is the only thing I would categorize as homeowner-grade. But for knocking quick clean holes in drywall it rocks.

I just checked out the Kreg system, that looks awesome, thanks! That looks ingenious.

Have you checked out the track saw? It looks another one of those, 'why haven't we ALWAYS done it this way?' things.

I have a couple long pieces of aluminum U channel that I clamp to the work to make a fence for jigsaw or circular saw cuts, but you have to spend the time figuring the offset of the blade from the fence.

I'm not sure I'll need a planer, but will give that some serious thought. Jointer maybe.

New saw blades are almost certainly in my future no matter what.

I think I have a good enough air compressor 20 gal. tank 135 psi. I haven't decided on a specific make or model of nail gun(s) yet, so I appreciate any evaluation of the DeWalt, Ryobi, Paslode, and others.

I'm definitely going to get a dozen or more clamps.

Got 2 shop vacs.

Thanks again!!

dvdhawk, post: 394049 wrote: Gentlemen, thank you! Keep the sug

dvdhawk, post: 394049 wrote: Gentlemen, thank you! Keep the suggestions coming.

Max, you do have a knack for torpedoing a budget.

I just go with my strengths, babe...

Have you checked out the track saw? It looks another one of those, 'why haven't we ALWAYS done it this way?' things.

Damn... something ELSE I gotta get...

Got 2 shop vacs.

Now yer' just braggin'! thumb

MadMax, post: 394042 wrote: Get the Kreg system!!!!!!!! I was an

MadMax, post: 394042 wrote: Get the Kreg system!!!!!!!! I was an idiot for not getting one until recently. Face frames and cabinetry in general is seriously simplified!

You don't need to get all the fancy clamps. You can use regular clamps just fine. Also, get a big set of the 3/4", 1" and 1-1/4" screws.

I see they have the screws in coarse and fine thread. Which are you using for most of your projects?

Update. We're done with the structural shell and are happy to b

Update. We're done with the structural shell and are happy to be under-roof. The next step is windows, doors, soffit/facia, to get to where it's completely buttoned up. I'm not going to start working on the interior until we're 100% dried in. I've also got a 32' x 20' concrete apron that needs poured in front of the garage doors and the frost-walls for the piece that connects the new building to our exisitng house that need poured. A pad around the side for the A/C unit and 2 more pads outside the doors. Which brings us back to, 'where did all that extra money I had budgeted end up?'

The footer + the ICF forms + 245 CY of concrete + 5 miles of #5 rebar + 1/2 mile of #9 rebar, WWM = right on budget

Roofing materials = within 1% of estimate from last year's materials list

4-man crew to Install Roofing Materials = about what you would expect

Both bills at the same time - ouch.

Excavation honestly got very complicated = double original budget, but no regrets with decisions made or work done.

Washed 2B river gravel, good Lord the river gravel.... 100 tons to begin with in Dec., 200 tons more in April for backfill and we may need one more truckload.

Several things have gone considerably higher than expected and I'm going to grind away at this stack of bills before I press on. I'd rather avoid a trip to the banker, and I don't want to make my contractors wait to get paid - so I sent them on to their next projects, while I work every job I can get. There's plenty to do, and sufficient money in the pipeline. The next step (windows, doors, etc.) is in sight.

I've got a 200A panel and some electrical supplies accumulated plus thousands of feet of LV wire ready to go in when the time is right.

Meanwhile... jobs to do, bills to pay, next step...

The Mantra of the Month: "How do you eat an elephant? - One bite at a time."