dvdhawk - I'm starting a new thread with details on the proposed ICF building project. Here's the background information our moderators like.

Location: Western PA -USA

If you looked at a satellite photo of my location you would see all the forests and farmland, and you might think that outside -> inside noise wouldn’t be much of a problem in such a rural setting. Not true. We just have different problems than the suburbs and cities. We’re in the middle of a small cluster of homes along one of PA’s primary 2-lane roadways and we’re just 1/2 mile from Interstate-80. We’ve got great neighbors and we all try to be respectful and not make too much racket, early or late. I personally don’t need much volume to be happy and I’m much more likely to pick up an acoustic guitar or play an unplugged electric. But due to some unresolved karmic debt from a past life, my son plays drums. Thankfully he’s not a basher, but still, a 16 yr. old drummer playing the kind of music 16 yr. olds and his friends would play. (on the loud side) I own no less than 3 decibel meters, and have never measured the dBs inside or out when he's playing. I’d have to guess 95-100 dB inside would be the maximum inside level.

Project Description:

Multi-Function 55’ x 32’ Multi-Level Building attached to existing home.

Goals of the entire building project:

To make the most sound-proof and energy-efficient building possible on a reasonable budget.

2-car Garage with Workspace and Storage.

Recording and Production Space for my solo projects, band projects, and my 16-yr. old son’s band(s)

Production Space for occasional outside recording projects, and A/V post-production.

Control Room that can double as client-friendly Video Screening Room

Rehearsal Space for me and my son’s bands ( they practice a lot more than us old guys )

Workspace, Office Space, & Storage for the A/V Contractor business.

Project Status: Making final decisions about design, construction scheduled to begin with footer work in the spring, basement walls immediately after, - March if we’re lucky. It’s not too late to make changes!

Known Construction Challenges:

Attaching to existing house at correct heights.

Sloping lot - 30ft. drop over 300ft. length of lot.

Excessive ground-water needs adequate drainage.

Driveway needs reworked.

The patience of my wife of 25 years, who does not like change.

Noise Issues: Typical neighborhood noises - not complaining, just listing all the things that could wreck a recording.

Road noise - cars, trucks, Harleys, punks with car stereos I can literally hear coming a half mile+ away.

Moderate truck traffic with potential for much more if they make I-80 a toll road through PA. (which state lawmakers are trying to do)

The big trucks are a problem here. They're either coasting and Jake-Braking down one grade, or going like hell to get up the other side.

Neighbor’s idling big rig - sometimes rumbles for hours at a time, especially in cold weather.

Snow plows - an earthshaking rumble as they scrape the ice and snow off the roads in the winter.

Barking bird dog(s) in their pen - sometimes hours on end - year round.

Hunting related gunfire - sporadic and seasonal.

Lawn mowers - Neighborhood lawn mower brigade runs for hours - spring through fall.

Motorcycles (on and off-road) - loads of Harley traffic and the occasional ATV or dirtbike on the property behind us.

Helicopters - the good folks at Stat MediVac fly over regularly, between 2 local hospitals and interstate accidents.

Jets - that’s right... Jets. A couple times a month - F18s, A10s, C130s, etc. ripping through here full-throttle at tree top level. We apparently live at a navigation point for training flights and they hit a spot 1/4 mile East of here and bank hard North just outside my window. That leaves us in the loud wash, but it doesn’t happen enough to be a huge problem. And heaven help me, I love watching them go by, when I can look fast enough.

Vocation: I run my business out of our medium-size 2-story farmhouse style home.

Sound/Video Contractor - specializing in churches & schools. (95% of my business)

Professional Sound System Installation ( mixers, power amps, speakers, mics, racks, the works )

Video Projection Systems - ( screens, projectors, presentation software )

Theatrical Lighting - conventional lighting consoles & dimmers, plus new LED technologies

A/V production - Pro Tools & FinalCut Pro (5% of my business)

Special Interest / Corporate Video Production

Radio Commercial Production

Remote Recording - Live Concerts etc.

Recreation:

Still making music 2-3 times a month in a 3-pc rock / blues band

Golfing, fishing, motorcycling ( not enough free time do to any of these lately )

Research:

I have several great books including Rod's, and I've been doing my homework, reading everything on the Auralex & GreenGlue sites, at John Sayers' forum, and recently joined up here at recording.org to name a few resources.

Drawings and Pics to follow because, 'That’s all I need in life, a little place for my stuff.' - George Carlin

Topic Tags

Comments

Speed kills, so I am not eager for that :) But I do look for the

Speed kills, so I am not eager for that :) But I do look for the detail and either I am missing it or it has yet to happen? Conduits, separate slabs, sand based slabs any type of preparation, electrical...anything?

Building houses I know, so we haven't hit a wall, so to speak, that I haven't seen. I'm a junkie ah-ite?

All valid questions Mr. Spacely. I can only use 4 pix per post,

All valid questions Mr. Spacely. I can only use 4 pix per post, so I haven't dwelled on the conduit, but about 4 pages back you'll see some of the conduit poking up out of the snow in one section of the control. They are below the basement slab - room to room, control room to equipment space, mixer to racks behind sweetspot [gray Schedule40 for electrical]. As recommended low-voltage positioned low in the room / high-voltage at ceiling height. Plus every pour has been preceded by all kinds of utility penetrations through the walls as needed for low-voltage and high-voltage wiring, ductwork, plumbing & utilities. And there a lots of 1 3/4", 2", 4" 6" sleeves in a variety of places to allow for wiring to pass through the concrete walls. [outside to GFI and exterior lighting / new meter base - electrical service entrance] [ water, natural gas, comm, sewage shared with the house. We've also got several places with round 14" sleeves through to accomodate 12" duct plus a sizeable square hole formed through the Insuldeck floor for another HVAC chase from the mechanical room off the garage.

The only area the basement slab connects from one room to the next is through the 2 doorways on either side of the stairwell. I don't believe they put any kind of break at those doors. The concrete for the floor does not touch the footer and is poured inside the ICF providing a 2 5/8" foam bumper around the floor in the CR and the TR. But if I determine I need to separate the slab, it's 2 x 3ft cuts. The Insuldeck slab at garage level has a thermal break in it dividing the garage from the inhabitable space. It should cushion the vibration front to back - in addition to keeping the garage floor from cooling the inhabitable space when you would want heat / and vice versa. There 5 or 6 heating/cooling zones all together.

The two small 4' 9" x 8' 5" iso-booths within the stairwell walls will have no use for an 11' 7" ceiling height, so I intend to box off several feet of that ceiling height and use that space to provide an area for pipes and ducts that can be isolated from the little isos.

well that's all I've got for now- it's 5:49am and I just got back from a job a short time ago with another one tonight, another bright and early Sun. morning, and so on.

Hey DVD. vibrations here and just wanted to let you know how im

Hey DVD. vibrations here and just wanted to let you know how impressed I am and how much I can empathize with the burnout kinda stuff. I get the money making to feed the money drain on the project thing. Right now i'm struggling financially (besides just the studio build) to keep progress forward, so I'm selling about anything that's not nailed down. Your build looks like fast movement, and it is, but the process to get to this point is very draining in many more ways than one, I know and just look what Max has gone through! I'm sure each one of us crazy enough to persue this dream has and will go through similar stress and is rootin' for ya all the way. Soooo...replenish, revive and keep on keepin' on. Yippie! It's so great to be insane huh?! (speaking for myself of course) I'll go back to lurking now but i just wanted you to know I'm out here rootin' for ya. ciao

Thanks JP, always good to hear from you, but sorry to hear about

Thanks JP, always good to hear from you, but sorry to hear about the belt tightening measures.

You're absolutely right (and know all too well) about the process. It was Fall 2007 when I first met with the guy who was going to take my design and draw up plans and give me approximate cost. Feb. 08, when we got the first set of plans that were somewhat close to the place where 'what I wanted' and 'what I could afford' intersected. Then Aug. 08 was when we got all the building permits and somewhat close plans approved by all the engineers and local authorities. Site prep - tree removal and excavating in Oct. 08. And then spent the rest of 08 and most of 09 waiting for the original ICF contractor to get a break in his schedule that was going to work for both us. He could have started in Nov. 09, but with winter bearing down on us I didn't like the prospects of having to put a roof on this thing in the dead of winter. And at the same time the economy was taking a nosedive, so I decided the smart thing to do was wait until Spring 09 - but then that guy got booked up solid again. Finally in the first week of Dec. 09 we got hooked up with a different Concrete Contractor and we were off to the races. A week and a half later, the footer was formed and poured and we were finally underway. After waiting so long, then the stress became... am I forgetting anything? At the pace they're going - will I be able to keep ahead of them with the things I need to do?

The Inspector visited this morning and gave the thumbs up for todays pour. The ICF salesman stopped in again today and brought another potential customer to take the tour. I told him if he's going to keep using my project as his company's 'model home', I was going to want a commission. He laughed - because he thought I was kidding. Naive people are just ADORABLE. It was also good to see the guy who will be setting the roof trusses. He came by to give me an idea of the specific place he wants the trusses to be dropped off. My General Contractor is expected to be back in action this week, and we could/should be setting trusses next week.

This is probably the last time you'll have to see the Putzmeister.

He was set up in front of the house today rather than down behind the basement door

If he wanted to show off, he could have easy reached from the far side of the house - that would be cool.

Some of the many sleeves for utility penetrations. These are through the very top of the basement wall and will pass under the attaching breezeway and through an access door on the existing house. The thinking at the moment is to put in a new/separate 200A electrical service entrance for the new building and share the rest of the utilities with the existing house. I don't expect the new building to require much gas or water.

Tomorrow should be a clean-up day, so we'll see if we can find anything else under the debris that's worth photographing.

Not much to report, waiting on roof trusses and the General Cont

Not much to report, waiting on roof trusses and the General Contractor to catch up from his time off.

The same sleeves shown a while ago, except from the inside. There are 1 x 4-inch , 2 x 6-inch , 4 x 2-inch to accommodate: incoming power, natural gas, water, phone, DSL, sat TV, security, plus outbound waste water.

A couple 14-inch sleeves for HVAC 12-inch round and several 6-inch for HVAC. That will all cut into the 11ft. height in that corner, but we'll box it in and trap the corner above the door. The relatively small iso-booth will not need a 11' 7" ceiling - so we're going to take about 4 ft. of the headroom above and use it for ductwork and silencers. With the raw dimensions of the room, [57 x 101] an angled ceiling averaging 84" should yield acceptable room ratios [ 1, 1:5, 1:6 ] for a small room. By my calculations using ratios (published by Eric Desart) 56 x 89.6 x 84 employing some angles and traps should be OK for a tiny room. I don't think the math cares that the small number is the width rather than the height.

Ductwork will also feed out the other side of the iso to the CR too (along with water lines for the in-floor heat - up by the ducts) Some additional gray electrical conduit and the white PVC is the radon-vent which will have to be run up all the way through the roof.

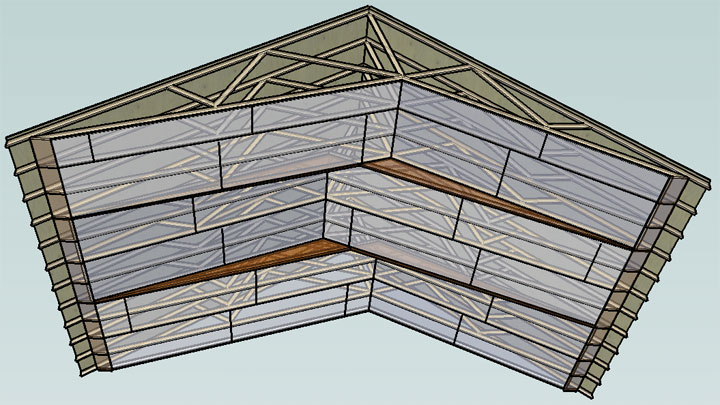

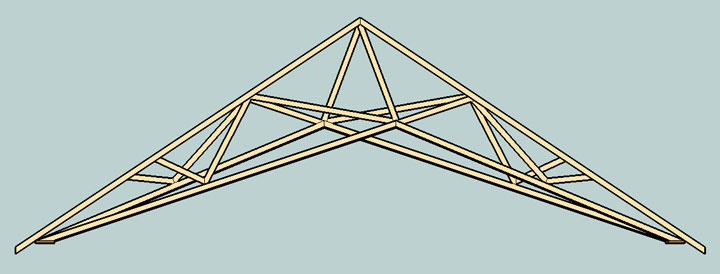

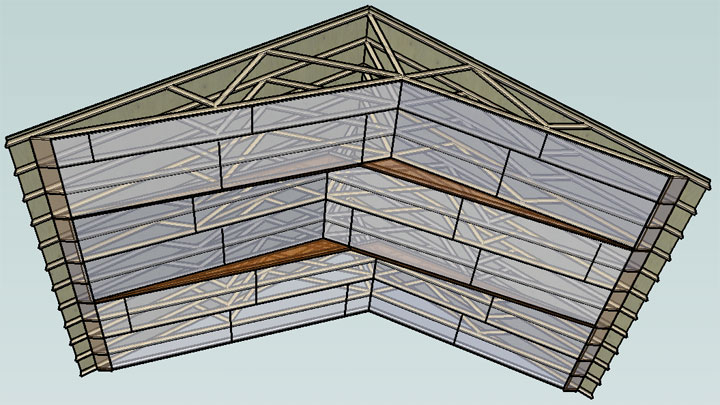

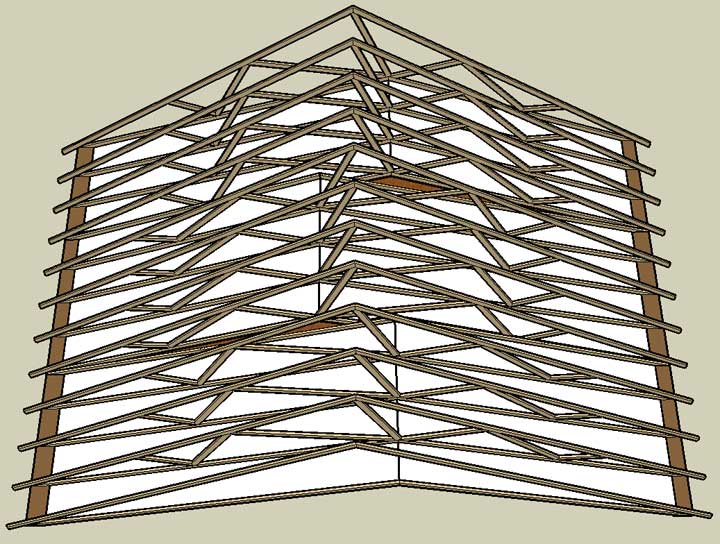

Two more 14-inch round duct sleeves (and a 2ft. service access) from the 2nd floor out into the scissor trusses over the vaulted ceiling of the 1st floor. We're using offset scissor trusses to create some variation to the ceiling. The roof pitch will be 8/12 . Inside the bottom chords will be 4/12 and 5/12 - meeting about 21" off-center. Alternating the off-set every few trusses - if that makes sense. So instead of just 2 ceiling planes - at least 6 planes.

I'd better try this with illustrations..... standby...

As I was trying to explain ... The trusses over the back of the

As I was trying to explain ...

The trusses over the back of the 1st floor are offset and we plan to switch directions every 8 ft. or so. This is what the two trusses would look like endview.

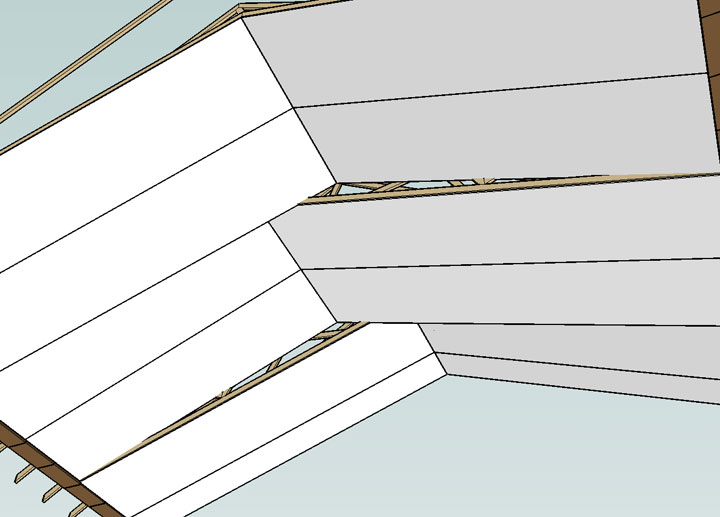

And this is what I'm trying to explain about the planes. How to handle the gaps is still being discussed. {more compound angles, vertical triangular pieces} - we'll see what works.

Why? edit: "So instead of just 2 ceiling planes - at least 6 pl

Why?

edit:

"So instead of just 2 ceiling planes - at least 6 planes."

4 planes. This is still symmetrical diffusion. I think I know what you are going for, but I would like to read what you read in order to have a better feel for why I think it is not worth the effort :)

"an angled ceiling averaging 84" should yield acceptable room ratios [ 1, 1:5, 1:6 ]"

This has been talked about at length, averaging, in the only one of two forums I hang out in. I'll give you my take...

When those guys, Sepmeyer and Louden did the work they did, it was inside a predictable rectangular room with hard boundaries using specific ratios. It was a process that was repeatable.

When we attempt to splay or alter those paths, the ratios have to be altered to account for that.

Averaging is something Eric might can do, but the rest of us, good luck :)

As a foot print to build a room, yes, I think that like you this is a fantastic starting point. But anything I do to change that, that now it is not a rectangular environment, averaging is as close to guessing as we may get.

Space, post: 343790 wrote: Why? It amuses me. For the cost o

Space, post: 343790 wrote: Why?

It amuses me.

For the cost of a couple 2x4s I can add a little variation to the ceiling. The guy who drew up my final plans thought of it. He used to own a studio that was cursed with low ceilings - maybe this is his revenge. He told me what he had in mind, I thought it would look unique, and don't see how breaking up the ceiling planes would in any way adversely affect the sound of the room. So we're proceeding in that direction.

If you explain to me why it's a bad idea say so.

It complicates the building process. It adds a level of difficul

It complicates the building process. It adds a level of difficulty that has no reward. If it were a smooth bending plane, maybe, that might be useful. But building all the jagged places directly overhead...it's bound to come back in your face...literally.

But, Dave, it is your build, you made it public, that is just my opinion, an educated opinion, but an opinion just the same. Still, hard data is always welcome.

Brien

I'm humbly wonering, why not keep external ceiling calcuable (i

I'm humbly wonering, why not keep external ceiling calcuable (is that even a word?), and build internal shell to suit? Unless you have a specific plan, it may conflict w/ internal design, and HVAC, at no benefit. While your design doesn't intoduce much more work/materials (they gotta put the roof up either way) contractors will say it will. i feel like more/correctly placed rockwool/insulation above a designed internal ceiling could yeild a similar effect, while leaving the trade workers (who are doing just "another job") to what they are used to. Plus, w/ a jagged roof like that, whoever puts on the roofing material (shingles?) will have a field day ($$$) at the so called "complications". Drainage will certianly be an issue, so will bending roofing material. My modest thought is- a consistent external structure will make room for a more consistent internal acoustic estimation/design.

K-metal perhaps you aren't used to reviewing drawings but the pr

K-metal perhaps you aren't used to reviewing drawings but the proposed method of truss installation does not affect the exterior roof planes it will only be two continuous planes. It only affects the interior ceiling and that only as often as you reverse the orientation of the trusses. As to whether or not an acoustic value surpassing the construction cost is achieved I don't have an educated opinion, though this will certainly create a nightmare in extra framing blocking, sheetrock install, acoustic caulking, finishing, etc.

kmetal, maybe it's the illustrations that are confusing, I shoul

kmetal, maybe it's the illustrations that are confusing, I should have done a better job in the top drawing of distinguishing the foreground truss from the background truss.

But as JG says - the pitch of the roof (exterior) is a normal 8/12, the pitch of the ceiling (interior) is a combination of 4/12 and 5/12 that creates the offset. Only the bottom chord of the trusses vary, the top pieces that make the "A" are all alike and will make a very conventional roof.

Maybe this will help clear that up:

The vertical areas could either be wood, as shown, or drywall.

dvdhawk, my advice, you are trying to create diffusion with the

dvdhawk, my advice, you are trying to create diffusion with the angled ceiling. Check the angles because this design is NOT an ideal diffusor. Do some number crunching, make some drawings, calculate the reflection points, get a graph on what this will actually do. This design will work, but only as long as it's done with the correct measurments.

Thanks camsr, I would like to note, this room is NOT the primar

Thanks camsr,

I would like to note, this room is NOT the primary recording room, just a more lively room for when that higher ceiling sound is preferred. [10' 6 at the sides, 16' 2 at the apex]

I have no illusions that this is an "ideal" method of diffusion, or even much diffusion at all. And honestly, I'll be surprised if I don't end up hanging some sort of absorptive cloud panels and other proper diffusors after the character of the finished room is revealed.

Admittedly the angles were a shot in the dark by the guy who drew up the plans. And I could draw reflections in 2D from a variety of locations in the room, til the cows come home - but I'm not sure how that helps me predict how a spherical radiation of low-end will behave in 3D in the room. One of the most enlightening developments in Max's meticulously crafted tracking room, is that he's still experimenting and finding the sweet spot(s) in his room for specific instruments. I'm sure proximity to the walls and the specific ceiling height in each area all come into play.

I've read all I can, but I surely don't have all the answers, and I'm sincerely open to suggestions.

So if you've got some hard data, a formula, or link you would recommend I use, I'd appreciate it.

Yeah, dumb post by me. Sorry. Still learning. The drawings po

Yeah, dumb post by me. Sorry. Still learning. The drawings posted were clear, i just didn't "read" em right.

Maybe some calculated angles at the long ends of room (thinking wall/ceiling compound angles) instead, would aid diffusion/bass trapping. Just brainstorming.

This is just a thought but, looking at pics of powerstations' "Rythm" Room, it seems to have a main truss, non-jagged ceiling, and NO compound angles at far ends. Can't tell what the ceiling clearance is. It, has extensive slat style woodwork, which i don't think you want in this build.

The "compound angles" i'm talking about, are on the Rough idea of powerstations' "Main Room", where there aren't parellels on any sides. Specifically the ceiling/ceiling/wall "V" or "A" shapes.

Mic technique can ruin a "good" room as well as make a "crappy" one useable. (bar sound gigs, and basement studio experience spoken for)

As i am listening to a fairly powerful weather storm (Massachusetts 3/14/10.), i hear rain tapping, and wind on my house. My concern is a conjoined roof design for your Non-primary live room.

Rock on! Keep up the incredible work!

IMVHO, EVERY room has it's own "sweet spot" and conversely... a

IMVHO, EVERY room has it's own "sweet spot" and conversely... a "worst spot" for whatever application.

It's what "we" define as the sweet spot and it's allusive and subjective qualification as to whether it gets a vote as to its level of suitability and desirability.

I am firmly a believer in my tracking room's geometry... not that I wasn't prior to building... but I have gained a LOT more confidence (read big brass nads) that this is as fine of a drum tracking room as you'll find for a room this size (and even some quite a bit larger) as there is.

It's not just the non parallel walls and not just the ceiling... but the room as a whole enclosure that makes it such a wonderful room to track in. However, I have a lot of confidence in saying that the ceiling geometry has a lot to do with it.

The geometry of the ceiling has a focal spot where the room mic could be just about anything... from a mono U87, a stereo pair, XY, ORTF, Blumlein to even a DECCA tree, and it won't matter... you'll get a great sound.

And that great sound is almost enough to be the sole source of drums (or whatever instrument you put in the "sweet spot") for a recording.

Again, not that I'm dissin' on your design, but I still encourage you to make a road trip down here for a day or so to check the shop out and see/experience it for yourself, before committing to your proposed design.

With as much cash as you'll bleed on this, you don't wanna have to bleed any more than you have to, right?

(btw... the build IS lookin' incredible!)

dvdhawk, post: 343898 wrote: So if you've got some hard data, a

dvdhawk, post: 343898 wrote: So if you've got some hard data, a formula, or link you would recommend I use, I'd appreciate it.

Check out this little program: [[url=http://[/URL]="http://www.randteam…"]ABEC[/]="http://www.randteam…"]ABEC[/]

It will do a 3d pressure field analysis which will help in designing the ceiling. Lucky for you, this program is simple, and the room is not very complex ;) You'll see why when you try it out.

Hi Brien, I just saw your edited post. I respect your input, s

Hi Brien, I just saw your edited post. I respect your input, so I'll address your questions - and a few of my own.

Space, post: 343790 wrote: 4 planes. This is still symmetrical diffusion. I think I know what you are going for, but I would like to read what you read in order to have a better feel for why I think it is not worth the effort :)

As for reference materials - I've read most of the usual suspects (Gervais, Newell, Everest, and a couple 20yr old college textbooks on Studio Techniques and the Physics of Music and Sound) and I can't say any of them have addressed this specific issue. The offset truss design was conceived by my friend who did the architectural drawings for my plans. He was born into the building supply business and was a local legend of live sound since the 70's. He owned and operated a studio for years along with a thriving audio install business. Probably about 10 years ago he was forced to change paths and take over the family business. So in addition to being a CAD wiz, well versed in building materials, building practices, and building codes, he really does know a thing or two on the topics of sound and acoustics - but I can't say if he is basing the design on a specific published theory - I'll have to ask him.

The reason I didn't take much persuading to buy into the concept was based on observations more than anything I'd read. I spend a significant part of my year with my head in other people's rafters doing install work. And what I've noticed over the years is that the old-school architects who wouldn't have relied on amplification generally did a much better job of tuning a room. And if there's a common theme I see in the building practices of these old churches that sound good, it's a wide variety of angles. High ceilings, plaster and exposed beams, wood and glass. Since these rooms have to be functional and look good too, it's all symmetrical relative to the room and it still sounds good. There are some unfortunate parabolic designs and there are some amazing sounding rooms that were built in the early 1900's. With a few exceptions, most of the stuff I see built from the 60's - 70's is pretty forgettable and the stuff built since the 80's is usually relying heavily on amplification with zero consideration given to acoustics at all. And whether it's built from the late 1800's or last week, the sweetest sounding rooms I've heard have had something interesting going on with their ceiling. They can't monkey with the floorplan without wrecking the function of the room, so they tend to alter the ceiling geometry. Just my observation...

So having said all that,

- Is this a room that I expect to be used for tracking very often? - No.

- Is this truss offset going to make a huge difference in diffusion? - Probably not.

- Is it going to make the room sound any worse? - I really don't think there's much danger of that.

- Is it going to take much extra effort? - GC who's setting the trusses and hanging the drywall says "No".

- Is this bit of effort going to net something that sounds a little better than no effort? - I believe it will.

- Do you hate it when someone asks a series question and then answers them too? - Yes, people who do that should be taken out back and beaten.

class="xf-ul">

Space, post: 343790 wrote: Averaging is something Eric might can do, but the rest of us, good luck :)As a foot print to build a room, yes, I think that like you this is a fantastic starting point. But anything I do to change that, that now it is not a rectangular environment, averaging is as close to guessing as we may get.

All true. If there's anyone who denies room ratios are at least a good starting point, I'd invite them to come stick their ears in my downstairs control room and tracking room. In their raw unfinished state, they have the exact same height and length - but about 3ft. different in width. The sonic difference is BEYOND night and day. The control room sounds very decent as is, with just a few building materials stacked in it, while the tracking room is nearly empty and unbelievably reverberant.

If I'm not mistaken, Rod has said somewhere that sloping the ceiling in a small booth can make a world of difference. And Eric, or Ethan say somewhere that averaging an angled surface into the ratios will be the best a mere mortals like myself will be able to do to get in the ballpark.

Again, we're so far from the stage of fine-tuning an iso-booth I don't know whether to laugh or cry. The only reason some of these topics have come up so early in the build is that with ICF construction you have to try to anticipate everything, because there is so little wiggle room later without involving hammer drills, jack hammers, and diamond tip saws.

So, we had 2 beautiful warm days (for March in PA) and the backf

So, we had 2 beautiful warm days (for March in PA) and the backfill problem has been dealt with. Here's the BEFORE picture with 3-5 ft. of mud covered snow in the trench.

I had the somewhat costly pleasure of watching a master excavator in action. It was an unbelievably tight fit between the new building and the house. It was just amazing to watch him swing the boom around with the bucket inches from the porch roof while the tub is missing the rain gutter by less than an inch. The rest of it was just dicey considering the amount of rock and dirt that had already caved into the hole he was parked over.

Two truckloads later (neighborhood of 50 tons) of dirt, rock, and snow later - we could hand shovel back down to the top of the footer and form-a-drain.

After the whole thing was mucked out, we got the waterproof layer applied up the first 6ft. and then banked in the first 100 tons of 2B gravel. There's between 75 and 100 more tons before we're finished. But now that we're 6ft high with the gravel on the front 1/3 of the building, the rest of the waterproofing material can go on and the rest of the gravel filled in.

.....I love hammer drills, diamond tipped saws and an apprentice

.....I love hammer drills, diamond tipped saws and an apprentice who loves jackhammers......Also a good hoe operator is a fine thing to witness. My last operator was a real gem. A couple of ditches to swimming pool equipment houses through existing services (Locators was only three feet off on average) back to an underground service lateral to parallel the run to the pool service. This guy could feel the difference in a rock, a root and a hot wire. Good stuff.

Davedog, post: 344150 wrote: ....a good hoe operator is a fine t

Davedog, post: 344150 wrote: ....a good hoe operator is a fine thing to witness.

MadMax, post: 344167 wrote: No kiddin'... A good operator is like watching a ballet.Intricate moves, performed so delicately and with amazing precision and finesse...

Good to know I'm not the only one who appreciates a good heavy equipment operator!

Since I was a kid I have always recognized when someone was a master of their craft. Guitar, piano, drums, electricity, plumbing, building, driving, wrenching, whatever - it doesn't matter what trade, a virtuoso will usually make me stop and take notice. I have always liked watching them do their thing, because there is almost always something in the way they practice their trade that you can apply to your own trade.

On another note, I may have stumbled into a deal on some doors. But it's too soon to get excited about that - not until they actually show up at my place anyway. So here's hoping..... I could use a break.

MadMax, post: 344340 wrote: About them doors... what's the werd

MadMax, post: 344340 wrote: About them doors... what's the werd bird? :confused:

Encouraging signs yesterday, I'm told it's going to take an exursion to a jobsite on my part, just think .... Somewhere in the world, they're tearing down an old hospital....

I heard about a hospital being demoed and asked a guy working on that project, "have you been taking any doors out of the radiology dept?" The guy says, "yeah, some of those doors are heavier than hell." I'm sure my poker face would have been gone by this point as I said, "yep, those are the ones I'd be most interested in having a look at."

Still just cautiously optimistic. It's going to take some good old fashioned finagling, but it looks good as of yesterday.

EXCELLENT!!! Those doors will be (in all likelihood) 2-6, 3-0,

EXCELLENT!!!

Those doors will be (in all likelihood) 2-6, 3-0, and PROBABLY 3-6 and 4-0...

If you do decide to use a larger door and saw it down, be sure you use a GOOD quality respirator when sawing... and be sure that your saw can handle the abuse of cutting through the lead.

The "rule of thumb" is 1/8" of lead up to a MINIMUM height of 7'-0" for diagnostic and CT. And they used to line the inner frames all the way around... so if you can get the frames too... DO IT!

If it's possibly in an oncology area... oooof... 3/8" isn't uncommon... up to 1/4"... Take 5 men and a small boy with ya if they are in oncology.

The hinges are gonna be worth the effort to save as well...

Good luck!!!

Keepin' my fingers crossed for ya!

dvdhawk, post: 344054 wrote: And if there's a common theme I se

dvdhawk, post: 344054 wrote: And if there's a common theme I see in the building practices of these old churches that sound good, it's a wide variety of angles. High ceilings, plaster and exposed beams, wood and glass. ... Just my observation...

Mine to. The volume of the room, height of the ceiling, the hard surfaces of marble, granite, oak, glass, etc. and the complete lack of sheetrock. That is a variable worth considering, since it has [sheetrock] ability to absorb and most of those other materials do not do that very well. So you get an acoustically live building. Not that it will not be lively, but the actual frequencies that are able to live in a sheetrock covered room are reduced in specific areas. 150-200Hz? Is that about right?

dvdhawk, post: 344054 wrote:

So having said all that,

- Is this a room that I expect to be used for tracking very often? - No.

- Is this truss offset going to make a huge difference in diffusion? - Probably not.

- Is it going to make the room sound any worse? - I really don't think there's much danger of that.

- Is it going to take much extra effort? - GC who's setting the trusses and hanging the drywall says "No".

- Is this bit of effort going to net something that sounds a little better than no effort? - I believe it will.

- Do you hate it when someone asks a series question and then answers them too? - Yes, people who do that should be taken out back and beaten.

class="xf-ul">

All I can think about this is it can add an interesting visual effect. That is always interesting, but it will be sheetrock correct? The volume of the room, which escapes me now, is important as you have said and I am learning. Even still, the chances of this ceiling getting covered by clouds or broke up in some other way...heck, it's your room...I'm just here for the beer, as they say.

dvdhawk, post: 344054 wrote:

If I'm not mistaken, Rod has said somewhere that sloping the ceiling in a small booth can make a world of difference. And Eric, or Ethan say somewhere that averaging an angled surface into the ratios will be the best a mere mortals like myself will be able to do to get in the ballpark.

There again these are efforts to reduce parallel boundaries, diffusion.

I finally have something, or rather found something that points me to specific reading material on room ratios. It comes from this link at JohnSays forum:

[[url=http://[/URL]="http://www.johnlsay…"]John Sayers' Recording Studio Design Forum • View topic - Room dimensions[/]="http://www.johnlsay…"]John Sayers' Recording Studio Design Forum • View topic - Room dimensions[/]

"And their work, in turn, was based on previous algorithms; primarily those of Louden.

And Louden, in turn, was based on Bolt (ca. 1938). What is often omitted in the presentation of Bolt's famous ratio graph is the supplemental graph that gives the volume dependence of the "ideal" ratio bubble"

Posted by Jeff D. Szymanski, Chief Acoustical Engineer, Auralex Acoustics, Inc.

At least four more books that I must get just to be able to stay in a constant state of confusion :)

And this is why I ask questions!!!

It was a beautiful day for swinging trusses. Gives a

It was a beautiful day for swinging trusses.

Gives an idea of height of the vaulted ceiling (7ft door)

A few hours later the realization ... we're one truss short because of some changes the lumber yard missed to the final floorplan. A bit frustrating since it has been brought to their attention over and over again. Apparently I'm going to have to personally shred the plans they have on file. So now we'll have to wait until tomorrow to set the last two trusses (the missing common truss and the gable end) and set them without the crane to boot. The GC sets trusses this way (by hand) all the time, but as you're watching the crane drive away you can't help think doing them by hand is an avoidable PITA.

The missing truss was delivered right before lunchtime. It and

The missing truss was delivered right before lunchtime. It and the gable end were up within 15-20 minutes after lunch. Hurricane straps, blocking and bracing etc. all done earlier in the day.

jg49, post: 344614 wrote: So did you alternate the vaulted trusses ? If so how many times does the ceiling change over the entire length?

I decided to go ahead and alternate the middle section more or less as illustrated below. The GC already has the 2x6's in place for the transition from one angle to the next. "Relatively easy", he says. He's doing the drywall too, and he's got a good handle on where we're going.

The drywall will be oriented the other way, but it should look something like this when it's finished.

camsr, post: 345446 wrote: It's looking less and less eastern bl

camsr, post: 345446 wrote: It's looking less and less eastern bloc every day. Not that it means anything, but it's sad to see it go.

It would have been a hard sell, telling the Mrs. we're attaching a GULAG to our old-fashioned farmhouse.

But now that I think of it, as I sit here with a stack of bills for all the roofing materials, 200 tons of gravel, the remaining ICF, etc. - It has become a self-imposed forced labor camp of sorts. So on that happy thought I'd better have my cup of gruel and get back to work.

dvdhawk, post: 345459 wrote: It would have been a hard sell, tel

dvdhawk, post: 345459 wrote: It would have been a hard sell, telling the Mrs. we're attaching a GULAG to our old-fashioned farmhouse.

But now that I think of it, as I sit here with a stack of bills for all the roofing materials, 200 tons of gravel, the remaining ICF, etc. - It has become a self-imposed forced labor camp of sorts. So on that happy thought I'd better have my cup of gruel and get back to work.

whats wrong with a GULAG ?

Back to lurking. Learning a bunch about ICF to. Thanx.

Hi PITA - believe me, I'm pro-labor..... but I'd also like to se

Hi PITA - believe me, I'm pro-labor..... but I'd also like to see if I remember what a day off is like.

I'm kinda at a standstill with the building at the moment - trying to catch up on some bills before I greenlight any more work. Next step windows and doors.

Hune, thanks.... Welcome to RO. I appreciate the compliment. I hope you'll come back and contribute more to the conversation than just your link.

2 months is pretty quick if you ask me! Maybe Space is just eage

2 months is pretty quick if you ask me!

Maybe Space is just eager to see how the inside gets setup.

But I'm sure not as eager as you, but then as you know (and I too) you can be as eager as you want but the wallet has to keep up! Ha!

Thanks for posting the pics, it gives me a good feel of the size especially with those last dimensions you mentioned.

snow, snow stay away.